Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Campaigns > Cutting-edge technology丨Advantages of SPCS structural system in underground space

Cutting-edge technology丨Advantages of SPCS structural system in underground space

2022.01.25

Trinity Construction

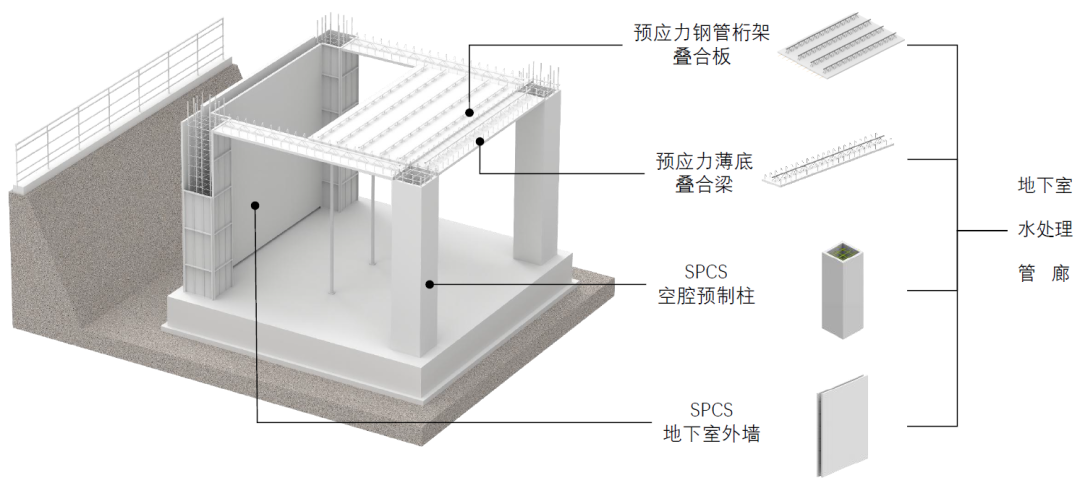

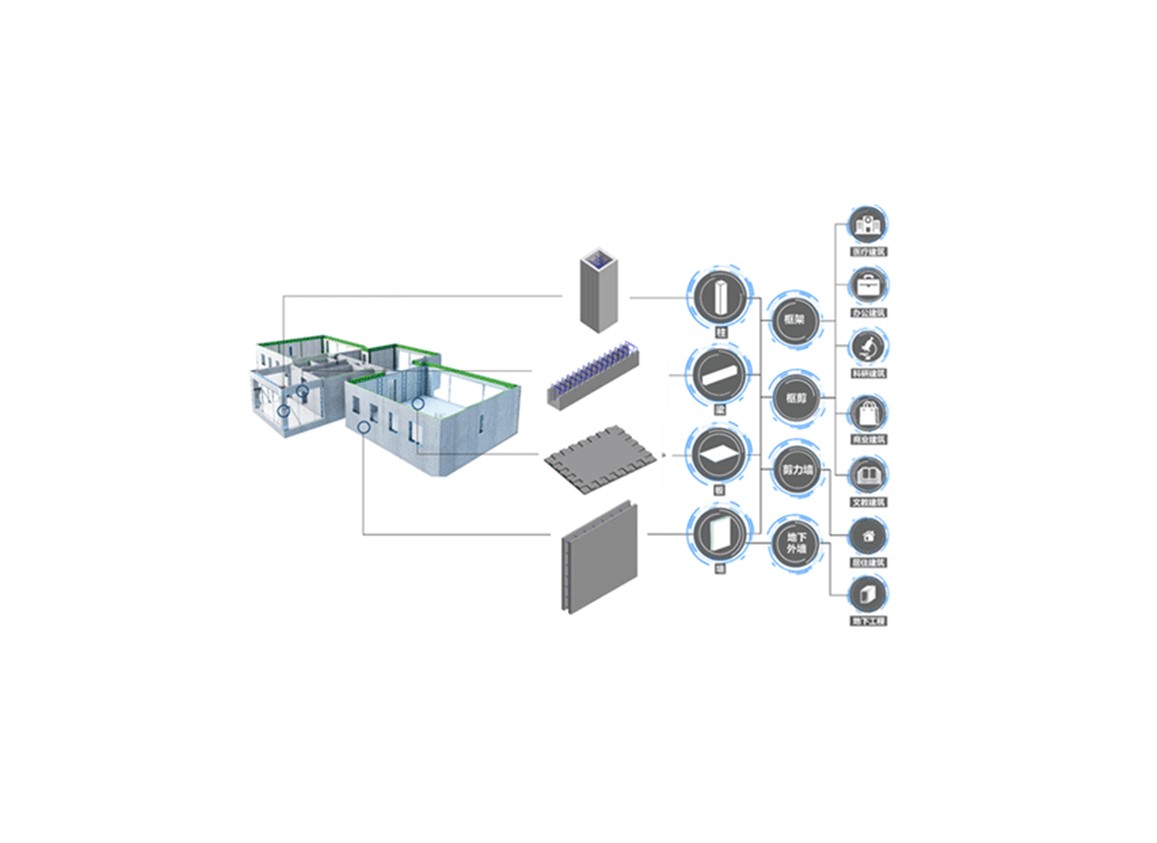

With the continuous development of the times, it has become a basic requirement for the construction industry to equip residential complexes with basements as parking areas. Due to the long-term erosion of groundwater, the underground space has a large hidden danger of water seepage, and the traditional basement construction has a series of problems such as long construction period, poor quality and high cost due to the large amount of support, formwork and steel bar. In this context,Trinity ConstructionScience and Technology Co., Ltd. and Shandong Wansida Technology Co., Ltd. jointly developed and launched the basement SPCS structural system, which realizes underground assembly through prefabricated exterior walls, prefabricated empty wall columns, PK beams and PK plates, which not only solves the problem of structural waterproofing, improves the quality impact caused by the operation level of workers, but also greatly reduces the demand for supports, templates and operators, greatly improves the construction speed, and greatly reduces the construction cost of underground space.

Fig.1. SPCS structure system in basement

Technical features:

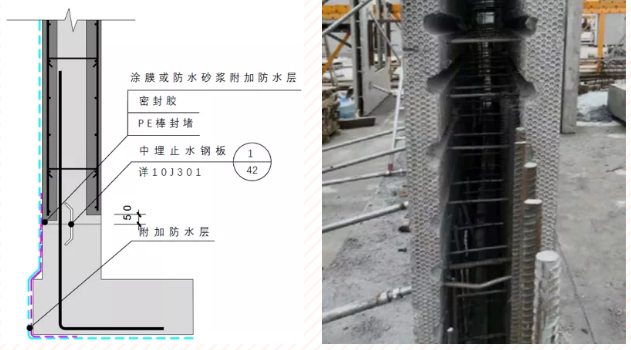

1. SPCS basement exterior wall: no reinforcement around the component, the internal cavity is poured back, and the reverse side of the bottom plate is inserted into the cavity for anchoring. The concrete in the cavity is connected as a whole, the structure of the component itself has high waterproof performance, and the joint position is waterproof with four layers (cast-in-place structure + waterproof sealant + two-layer membrane).

Figure 2 SPCS basement exterior wall node diagram and entity diagram

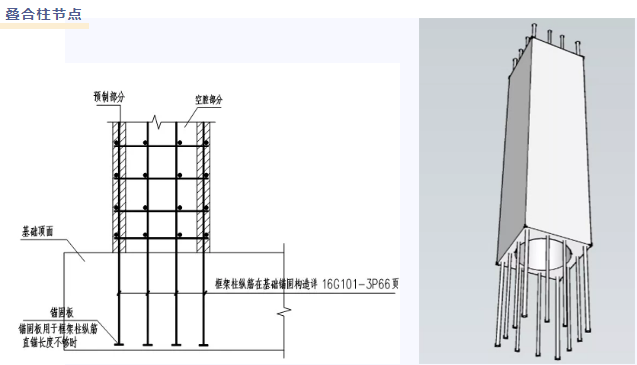

2. SPCS cavity prefabricated columns: two types of hollow wall columns

1) The two ends of the component are reinforced, the internal circular cavity is formed, and the lower steel bar is inserted into the foundation beam and the cushion cap steel bar for anchoring; The calculation method and scope of application are completely consistent with the traditional cast-in-place reinforced concrete columns, and can be applied to all basement structures.

Superimposed column nodes

Fig.3. Node diagram and model diagram of SPCS cavity precast column

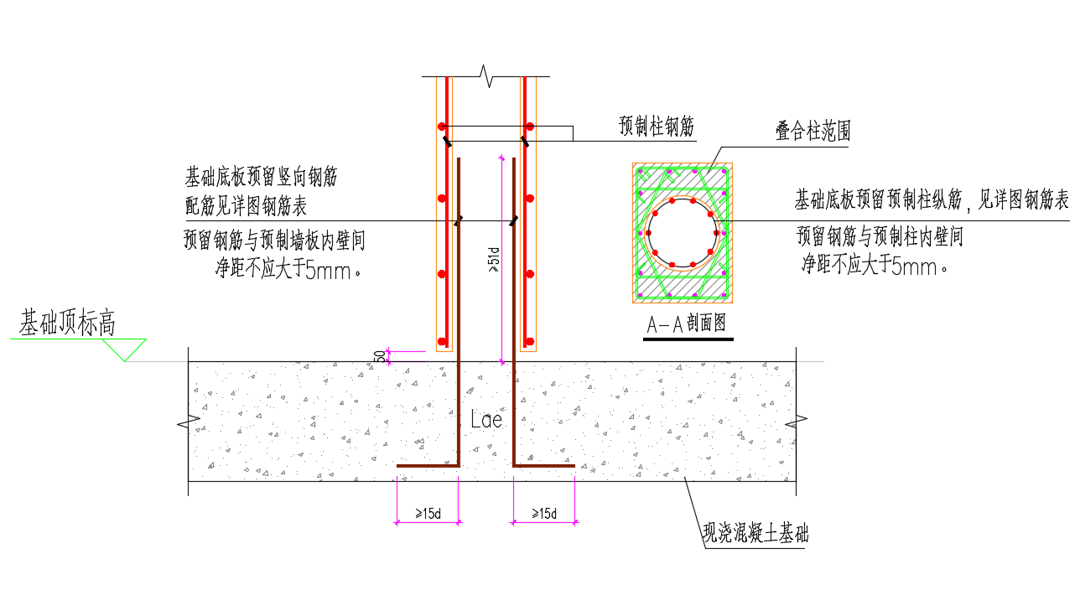

2) The lower end of the component is not ribbed, the cavity inside the component is formed, and the construction adopts the method of cavity interpolation reinforcement connection, which greatly reduces the production difficulty and improves the installation speed of SPCS hollow wall column by optimizing the structural measures and simplifying the connection mode.

Fig.4. Node diagram of SPCS cavity precast column

3. Prestressed thin-bottom superimposed beam: the prefabricated components are light, the prefabricated part is thin, the cast-in-place proportion is large, the integrity is good, the stiffness is large, and the prestress is high, which can effectively reduce the beam height, improve the net height of the basement, and achieve the effect of free decoration.

Fig.5. Solid diagram of prestressed thin-bottomed superimposed beam

4. Prestressed steel pipe truss laminated plate: The laminated plate adopts steel pipe truss prestressed tendons with high strength, thin thickness, light weight, good overall performance, and a maximum span of 12m, which can effectively reduce the number of supports; The plate adopts a dense spelling method without post-pouring belt, and the molding quality is good.

Fig.6. Solid diagram of prestressed steel pipe truss laminated plate

The application of SPCS structural system in basement space mainly has the following technical advantages:

Advantage 1: Faster construction

Fig.7. Field view of the exterior wall of the SPCS basement

1. The basement adopts SPCS prefabricated cavity wall and empty wall columns, which effectively reduces the workload of steel bars and formwork projects by more than 90%;

2. The horizontal structure adopts PK3 type laminated plate. PK3 laminated plate + PK beam has large stiffness, which can realize the advantages of large span, dense assembly, less support and less formwork;

3. The maximum span of PK3 laminated board can be 12m, which fully meets the needs of the basement structure, and the number is small if the size is large, which effectively reduces the number of hoisting;

4. Reduce the temperature stress shrinkage time of concrete;

5. The production of prefabricated components is synchronized with the foundation construction;

6. Reduce decoration time such as plastering;

7. In winter, rainy season, windy weather will not be affected, and the construction period can be controlled.

Advantage 2: High efficiency of earthwork backfilling

Fig.8 Comparison of slopes of traditional basement and SPCS structural system

In the traditional basement, the distance between the outer wall and the slope is 800~1000mm, and the amount of earthwork excavation and backfill is large and the cost is high; Using SPCS structural system, the distance between the exterior wall and the slope can be reduced to 300~500 mm, and the amount of backfill is small and the cost is low.

Advantage 3: lower beam height, less excavation, reduce buoyancy

Fig.9. Field diagram of PK beam and PK board

1. Using PK3 plate and prestressed superimposed concrete wide flat beam, the beam height can be reduced by 300-400mm. Therefore, under the condition that the net height remains unchanged, the amount of foundation pit earthwork excavation can be reduced;

2. Because the amount of earthwork excavation is reduced, the foundation in the area with a higher groundwater level is subjected to less water buoyancy, thereby reducing the number of anti-floating anchors, or bolts with smaller uplift bearing capacity can be used.

Advantage 4: Good quality of finished products

10 Field renderings of SPCS structural system

1. SPCS wall and PK3 board have good appearance quality and can achieve the effect of fair-faced concrete;

2. The exterior wall of the SPCS basement and the PK3 board can be densely assembled, the joints are neat, straight and beautiful, the overall appearance is good, and it can be decorated without decoration.

Advantage 5: The pipeline laying is simple and convenient

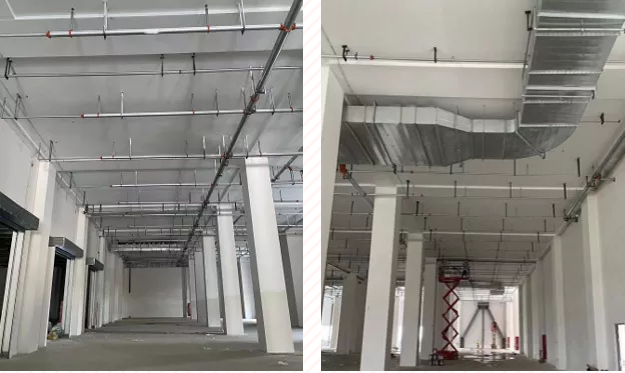

Fig.11 On-site pipeline layout

The bottom equipment pipelines of PK3 laminated plates and PKL laminated beams are easier to lay, more convenient for construction, reduce bends and avoidance, and save equipment pipelines.

Advantage 6: Good comprehensive benefits

1. Due to the fast construction speed of the basement, the sales node can be reached in advance, which brings greater capital benefits;

2. The basement can also be used as a material warehouse or processing room to relieve the site pressure on the construction site;

3. The municipal, garden, landscape, lighting, etc. of the follow-up construction can be inserted into the construction in advance to shorten the total construction period.

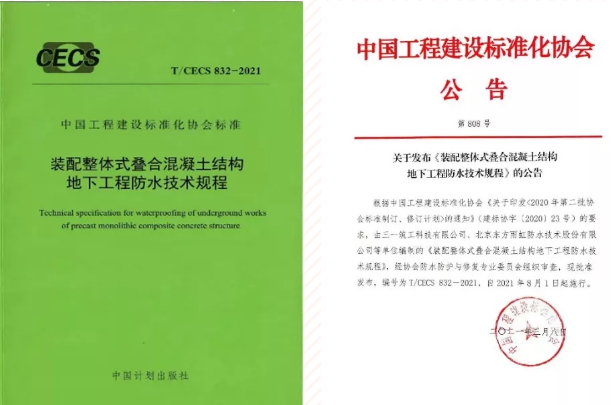

In order to further improve and promote the application of the basement SPCS technology system, the China Engineering and Construction Association standard "Technical Regulations for Waterproofing of Underground Engineering of Assembled Monolithic Superimposed Concrete Structures" T/CECS 832-2021, edited by Sany Construction, has been officially implemented on August 1, 2021.

Fig.12 Technical specification for waterproofing of underground engineering of assembled monolithic superimposed concrete structure

At present, the basement SPCS cavity exterior wall and hollow wall columns have been successfully promoted and applied in the Changsha Yungu Jiayuan project and the second phase of the Loudi Trinity Block project, and have been highly praised by all project personnel, industry experts and relevant government leaders for its increasingly mature technical system and strong advantages. It is believed that with the joint efforts of Sany Construction, Wansda and industry personnel, the basement SPCS structure system will become the mainstream technology of the prefabricated building industry with a vigorous development trend, give full play to the advantages of the system of "better, faster and cheaper", and realize the great vision of "making the world no difficult to do buildings".

SPCS structural system

Structural standardsRecommended products

Next article:The year is auspicious, and the year is healthy!

0 comments

Related testimonials

The power of example|Lu Yuelei, there is no time difference in service, and responsibility knows no borders

2025.07.08

Today's summer | The heat wave witnesses the struggle, and the sweat pours the dream

2025.07.07

We watched! 412 electric mixer truck endurance measurement [reprint] from Huzhou Xiaoluo

2025.07.02

0 comments