Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

"Stand" takes the lead | Sany X8 series engineering station debuts!

2022.03.21

In recent years, with the continuous promotion of national policies and the huge demand for infrastructure projects such as high-speed rail and high-speed,Concrete batching plantThe number has grown rapidly and has become an indispensable equipment in construction. However, with the acceleration of the pace of national infrastructure construction, the limitations of ordinary mixing plants such as long delivery cycle and inconvenient transfer are becoming increasingly prominent.

In order to break through this limitation and meet the customer's demand for rapid delivery and rapid production of the mixing plant to seize the market, the Sany R&D team has devoted itself to tackling key problems and launched the X8 series containerized engineering station, referred to as the X8 series engineering station.

The station breaks the traditional on-site construction of the installation method, with the characteristics of fast delivery, accurate measurement, efficient production, etc., and is equipped with a special control system for high-speed rail, which is the main product of the future engineering station, which can be put into use in 7 days at the earliest, giving you the opportunity to "station"!

Fast shipping and fast loading

Containerized batching plant: The product is designed based on the container structure, and the operation yard is more efficient.

Highly integrated modularization: metering layer, mixer pre-assembly and delivery; The liquid and gas supply pipelines and electrical components are all pre-installed, and they are quickly assembled on site; The structure of the main building is modular, and it can be put into use in as fast as 7 days.

Precise metering

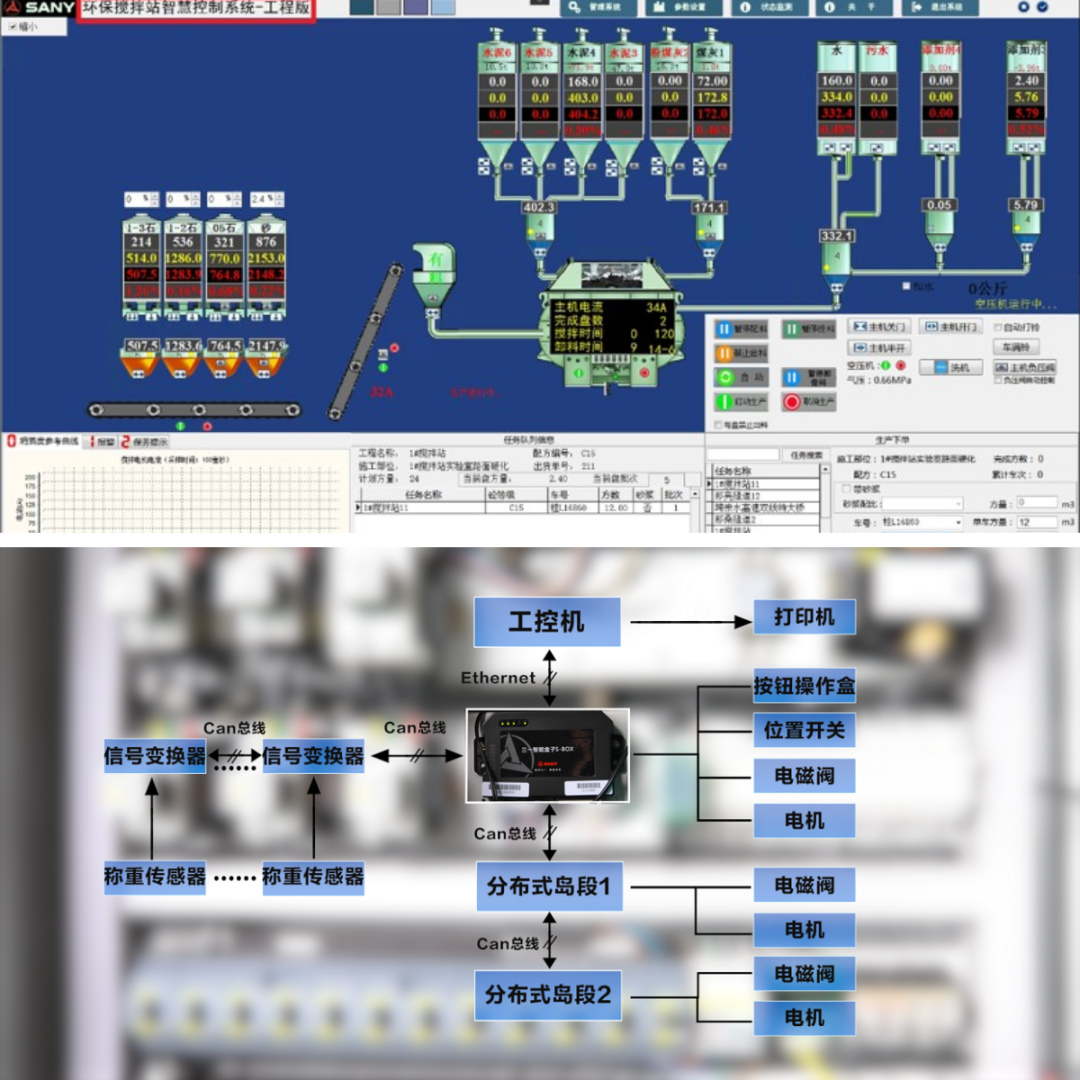

The industry's first CAN bus control technology for mixing plants, full digital transmission, stable and reliable; The special control system of high-speed rail is used to achieve accurate measurement. At present, the system has been maturely used in nearly 100 sets of high-speed rail stations.

The new weighing control algorithm improves the measurement accuracy and provides an information interface to meet the information needs of customers.

Batching station: aggregate precision weighing door adjustment rod, adjustable opening size; Add cylinder throttle valve, slow opening and fast closing; The admixture weighing system can be equipped with a precision weighing device;

In addition, it also adds a number of functions such as the selection of coarse weighing time sub-spiral working conditions, the automatic prohibition of discharging of each plate, and the alarm of vehicle data exceeding the standard to meet the needs of different customers.

Efficient production

No dry running: The seamless material flow technology of the mixing plant is used to eliminate the empty material and stacking of the inclined belt, and the aggregate batching efficiency is increased by 20%.

Non-empty: the use of intelligent waiting technology, automatic judgment of production conditions, aggregate conveying time reduced by 4S; According to the bulk density of the aggregate, the optimal opening time of the waiting hopper is matched, and the opening time of the waiting hopper is reduced by 2S+ on average.

Boiling stirring: Sany double-cycle boiling stirring host, optimizing the shortest mixing path, 360° all-round boiling and stirring of materials, full and uniform mixing, stirring efficiency increased by 10%, more than 4-5 trays of stirring per hour.

Stable and reliable

Less frequency of washing: The mixing host adopts anti-lock shaft technology, which is still as clean as new after producing 20,000 trays, and the frequency of washing is the least in the industry;

Stable and reliable quality: the main machine, batching station, assembled powder tank, etc. are manufactured by the full-process automated production line, and the blanking, molding, welding, painting, and assembly are fully automated, with shorter production cycle and higher stability.

Born for infrastructure projects, Sany adheres to the concept of "all for customers, all from innovation", and launches a series of Sany X8 engineering stations to lead innovation and help the intensive development of national engineering construction.

In the future, Sany will lead the development of the industry with smarter, more advanced and more reliable mechanical equipment and complete solutions, and boost the construction of a great country.

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationNext article:The spring breeze blows, and the warmth is born!

0 comments

Related testimonials

Low inlet strong load丨12T pure electric low-inlet chassis

2025.06.30

A new benchmark for kitchen collection and transportation丨12T low-entry kitchen truck

2025.06.29

Xibei Power and Sany Renewable Energy have cooperated strategically to jointly promote the application of sodium battery energy storage

2025.06.29

0 comments