Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Campaigns > SPCS technology: solve four major construction problems for prefabricated buildings

SPCS technology: solve four major construction problems for prefabricated buildings

2022.03.21

Trinity Construction

01 Identify the problem and grasp the pain point

With the rapid development of prefabricated buildings, the problems of traditional prefabricated buildings in the external wall are becoming increasingly prominent, including water seepage at the root of the external wall, difficulty in centering the steel bar, and falling off of the external wall insulation board.

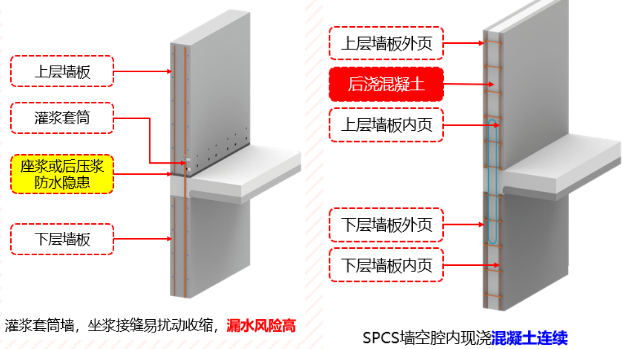

1. The traditional PC exterior wall is often due to the fact that the sleeve grouting is not easy to compact, or the upper and lower joints of the wall are easy to disturb and shrink, resulting in the hidden danger of water seepage at the root of the wall, as shown in Figure 1.

Figure 1: The traditional PC solid wall has a large hidden danger of water seepage

In 2021, the "Notice on the Special Inspection of the Construction Quality of Prefabricated Building Structure Engineering Organized by the Shanghai Construction Engineering Safety and Quality Supervision Station" (Document No. 50 [2021] of Shanghai Jian'an Quality Supervision) wrote: In this inspection, a total of 22 unit projects were tested by borehole endoscope method for sleeve grouting fullness, of which 7 projects did not meet the requirements, and the pass rate was only 68.2%.

2. The traditional prefabricated wall adopts the vertical connection technology of grouting sleeve. It is difficult to connect the rebar alignment with this technology, and workers who lack professional ethics will sometimes cut off the rebar directly because the rebar alignment is too difficult, which will directly lead to major safety hazards in the structure. This is shown in Figure 2.

Figure 2: Traditional prefabricated wall alignment is difficult

3. At present, the external wall insulation board on the market often causes a large area of the insulation board to fall off and catch fire due to improper material selection and non-standard construction, which brings serious harm to the safety of people's lives and property. This is shown in Figure 3.

Figure 3: Exterior wall insulation board falls off and catches fire

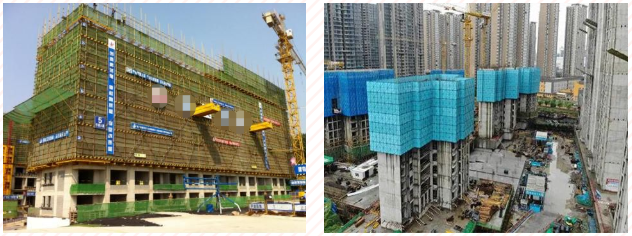

4. In the construction stage of traditional cast-in-situ structures, it is necessary to lease climbing frames or erect external scaffolds for façade formwork support, exterior wall structure repair, exterior wall masonry, façade decoration and other operations (as shown in Figure 4). A large number of external protective frames have greatly increased the cost of the project.

Figure 4: Exterior scaffolding construction

02Innovative technology solves problems

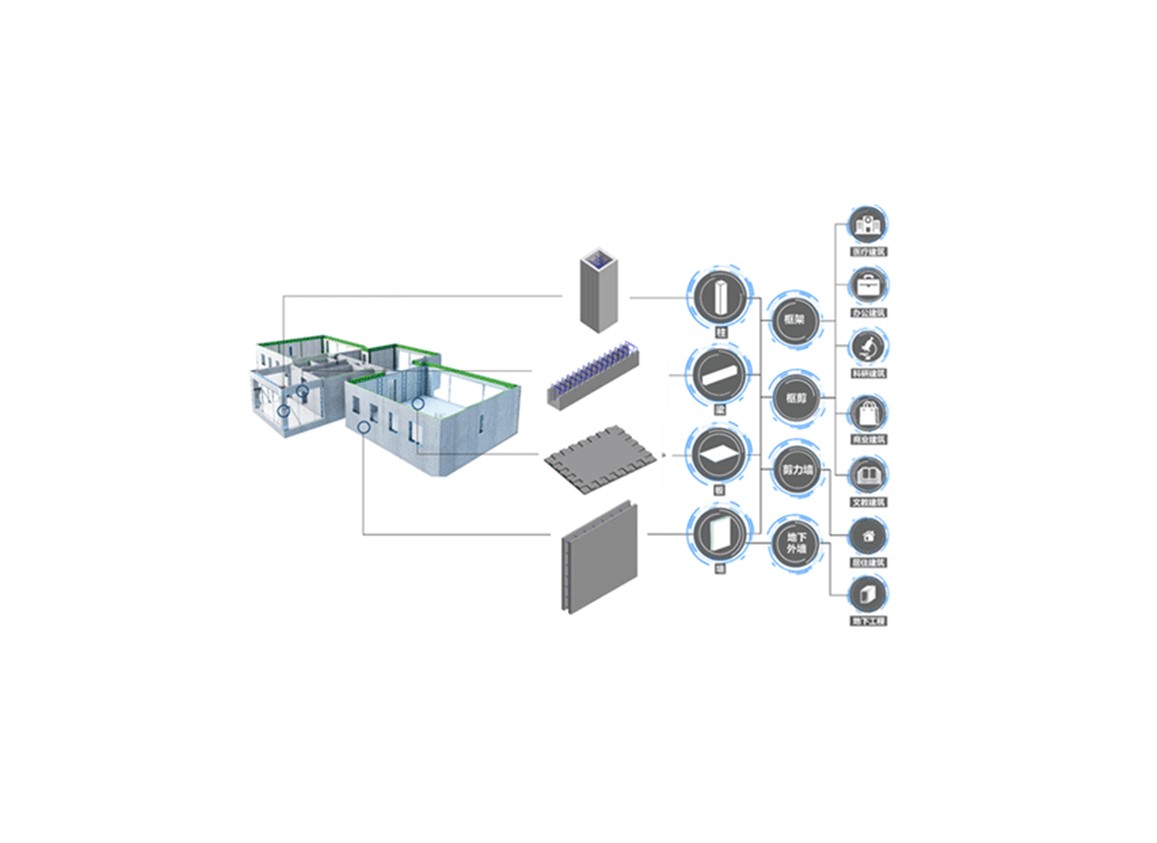

In response to the above problems,Trinity ConstructionThe R&D team of Science and Technology Co., Ltd. has successfully developed the SPCS structural technology system based on the technical route of "cavity lap plus post-casting, equivalent isomerism is good and fast and saving". The structural technology system can play a number of significant technical advantages in the exterior wall part of the building, including good waterproof performance of the exterior wall, less formwork of the exterior wall, integration of thermal insulation, light weight and easy construction, good appearance and quality of finished components, and thin plastering.

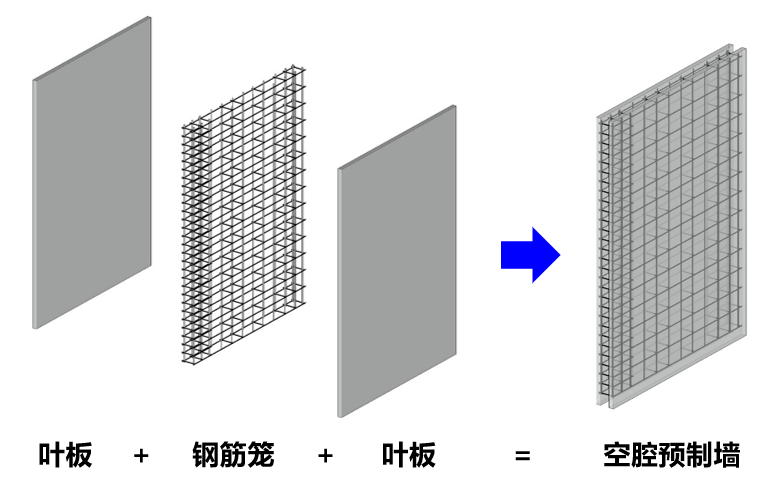

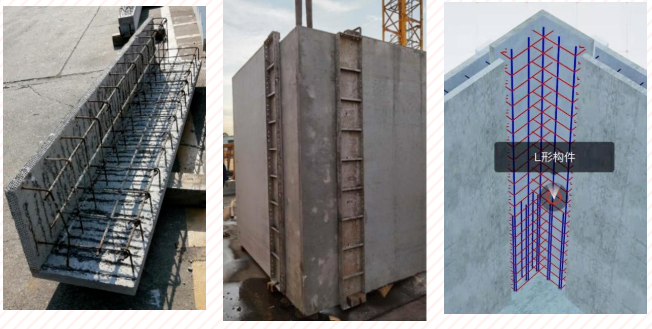

The basic form of SPCS cavity wall components is "fully prefabricated on both sides, no reinforcement on all four sides, large cavity in the middle, and strong connection of ladder reinforcement" (see Fig. 5). Among them, two-sided full prefabrication refers to the production and prefabrication of two-sided concrete slabs in the factory; The practice of full prefabrication on both sides realizes less lashing, less formwork and less labor on the construction site. The four sides do not have reinforcement, that is, the longitudinal and transverse steel bars in the two-sided precast concrete slab do not extend out of the slab; The practice of not producing ribs on all sides realizes the standardization of the mold in the production process, and there is no need to open rib grooves on the mold. The large cavity in the middle refers to a large cavity left in the fully prefabricated slab on both sides, and the cavity part will be poured with concrete in the construction stage. The practice of large cavity in the middle can reduce the weight of the component, increase the size of the component, and realize the advantages of less joints, less formwork and less binding of large components. The strong connection of the ladder bar refers to the effective connection between the ladder reinforcement and the vertical longitudinal bar, so that the two-sided prefabricated slab will not be misaligned due to external force in the transportation link and construction link.

Figure 5: Basic form of SPCS cavity wall

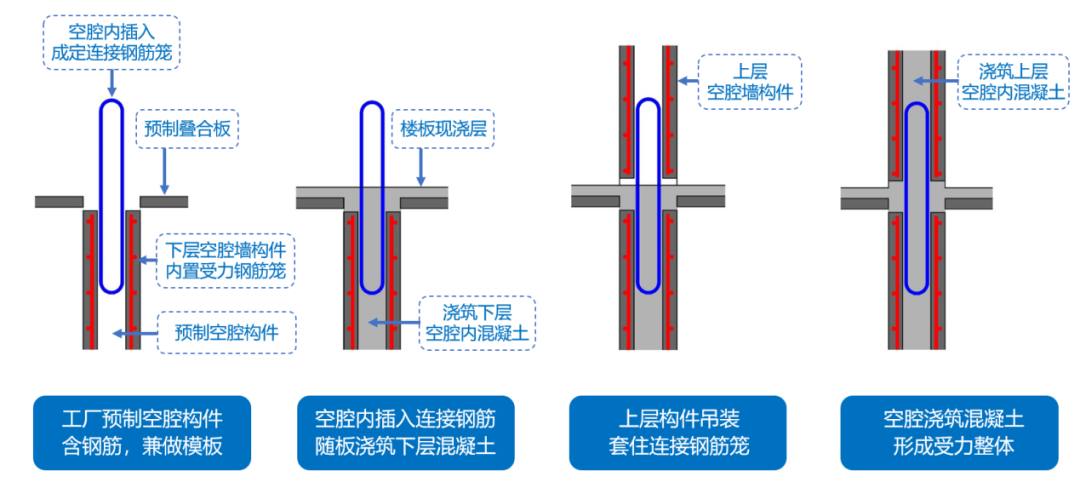

Figure 6: Vertical connection of SPCS cavity wall

SPCS cavity wall "cavity + lap + post-pouring" up and down connection mode (as shown in Figure 6) is a kind of "industrial post-pouring" technology, which not only retains the traditional cast-in-place practice, the overall safety, good waterproof performance, high quality, but also uses the way of industrial production to improve the production efficiency and construction efficiency, reduce the construction cost.

03 Obvious advantages and wide acclaim

Advantage 1: The waterproof performance of the exterior wall is good, and the vertical connection form of the SPCS exterior wall adopts the cavity + lap + post-pouring method for upper and lower connection (as shown in Figure 6). This connection form can eliminate the hidden danger of leakage of traditional assembly, so that the prefabricated part is closely integrated with the cast-in-place part (Figure 7).

Figure 7: Waterproofing structure of SPCS cavity wall

Advantage 2: Exterior wall dense spelling less formwork SPCS cavity wall can use exterior wall dense spelling technology to achieve less exterior wall formwork and avoid wrong tables. SPCS cavity wall close-fitting technology is not only suitable for slotted joints (as shown in Figure 8), but also can be applied to L-shaped joints (as shown in Figure 9).

Figure 8: "One" character dense spelling node

Figure 9: L-shaped close-knit node

Advantage 3: Integration of external wall insulationIn order to solve the problem of fire and falling off of traditional external thermal insulation, Sany Construction Engineering has developed SPCS external wall insulation integration technology, which can realize the integration of external wall insulation, waterproofing, fire prevention and structural functions. In addition, after the installation of the SPCS exterior wall using this technology, there is no need for subsequent external construction, reducing the risk of working at height and significantly improving the construction speed. For the integrated technology of thermal insulation, Sany Construction has launched a variety of processes, see Figure 10 for details.

Figure 10: Three processes of thermal insulation integration

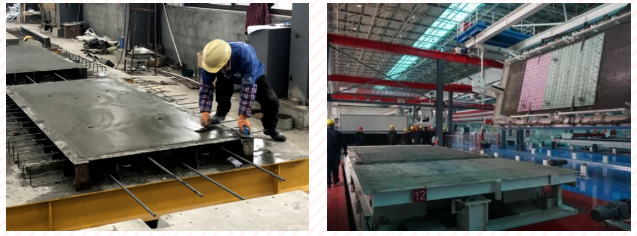

Advantage 4: Light weight, large size, less joints, easy constructionAt present, the longest size of SPCS exterior wall components produced by Sany Construction can reach 8m, and the weight is only more than 3 tons (Figure 11). Due to the internal cavity of the SPCS cavity wall, the vertical lap rebar is easier to center, the lifting is faster, and the self-weight of the component is lighter than that of the solid wall. Under the condition that the tower crane model remains the same, the size of the SPCS cavity wall can be larger than that of the solid wall, so that there are fewer joints between the walls, less on-site formwork binding, and the construction is faster.

Fig. 11: SPCS cavity wall has a light weight

Advantage 5: The quality of the finished components is good, and the traditional solid wall system is produced by a single-sided mold table, which requires manual plastering, which not only consumes a lot of man-hours, but also requires the surface production accuracy of manual plastering is difficult to control. Due to the intelligent production of double-sided formwork, the SPCS exterior wall has good appearance quality, which can achieve the effect of fair-faced concrete, and the flatness can reach within 2mm. (As shown in Fig. 12), the SPCS wall can easily adjust the position of the wall due to the light weight of the components, so that there is basically no misalignment between the cast-in-place nodes between the walls and the prefabricated walls. (Figure 13)

Fig. 12: SPCS cavity walls are produced with double-sided die tables

Figure 13: SPCS cavity wall has high flatness

It is reported that at present, SPCS cavity wall has been successfully promoted and applied in many projects in recent years, and has been highly praised by project personnel, industry experts and relevant government leaders for its increasingly mature technical system and strong technical advantages.

SPCS structural system

Structural standardsRecommended products

Next article:Sany mobile screening station was released

0 comments

0 comments