Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Campaigns > New breakthrough|Plastic formwork was successfully applied in Yungu Jiayuan project

New breakthrough|Plastic formwork was successfully applied in Yungu Jiayuan project

2022.03.22

Trinity Construction

Since the start of the SPCS architecture of Building 3# of Changsha Yungu Jiayuan Project in October 2021,Trinity ConstructionTechnology Co., Ltd. is constantly experimenting with the use of different templates. The plastic formwork has been used in all nodes from the beginning of the node test stage to the present. For the first time, the perfect combination of plastic formwork and SPCS system is a further step on the road to realizing the vision of "industrializing buildings".

1. Project Overview

The Yungu Jiayuan project is located in Sany Industrial City, Economic and Technological Development Zone, Changsha City, Hunan Province, with a total construction area of about 240,000 square meters, including a basement construction area of 51,000 square meters. Building 3 of this project has a building height of 72.35m, a construction area of 11,626 square meters, an SPCS application area of 9,492 square meters, a construction area of about 452 square meters per standard floor, and a floor height of 2.95m.

Figure 1 Project renderings

Figure 1 Project renderingsSecond, the introduction of plastic formwork

The plastic formwork panel material used in Building 3# of Yungu Jiayuan Project is made of PP+ long glass fiber, which has the characteristics of moisture resistance, acid resistance, alkali resistance and corrosion resistance, and can be sawed, planed and nailed, which is energy-saving and environmentally friendly.

Light weight: the weight of the formwork is about 15KG/㎡, light weight, complete specifications, light support and removal of the formwork, safe and reliable construction operation and handling, low labor intensity, and high construction efficiency.

High turnover rate: the formwork material has the advantages of high strength, strong toughness, impact resistance, strong elasticity, and is not easy to deform, and the turnover times are about 60 times, which can meet the turnover construction operations of most projects.

Fast installation speed: the professional handle of the formwork is quickly connected, and the thread removal is simple, which greatly saves labor costs and material costs, makes up for the defects of general wood formwork and paste formwork, and shortens the construction period.

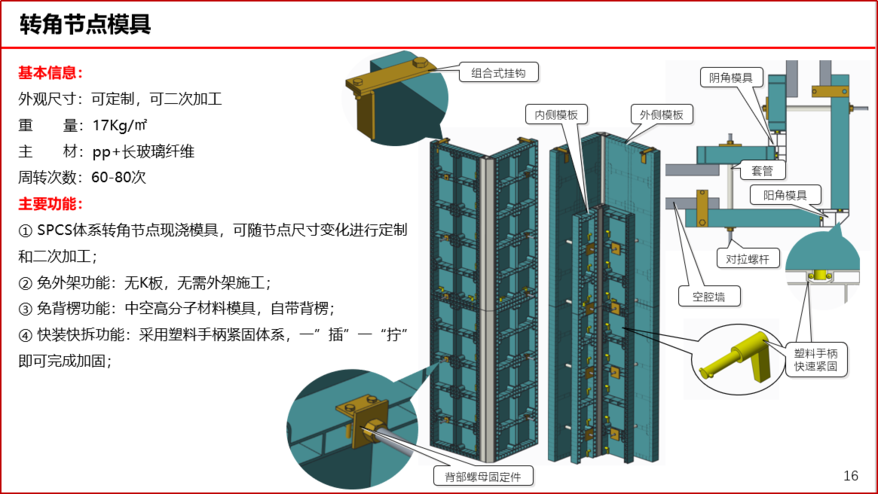

Fig. 2 Corner node mold

Fig. 2 Corner node mold3. Vertical template application

The installation of the vertical plastic formwork in Building 3 of the Yungu Jiayuan project can be completed by only one person, and the whole process of real-time installation and demolition process on site is as follows:

Figure 3 The whole process of vertical formwork installation and dismantling

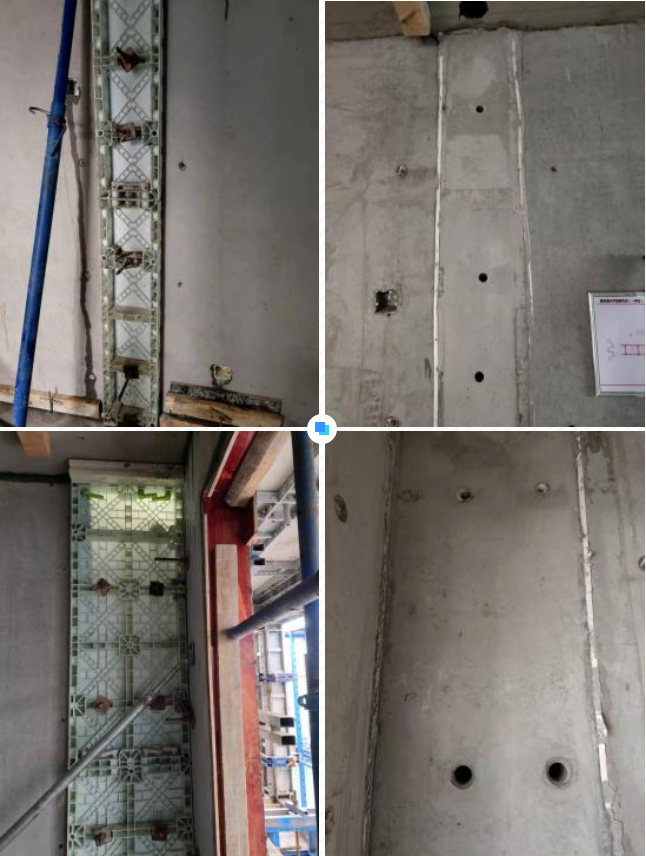

The practical application of vertical plastic formwork in Building 3 of Yungu Jiayuan Project is as follows:

Fig. 4 Sensory effect of vertical formwork (left) installation and demoulding (right).

Fourth, the application of horizontal templates

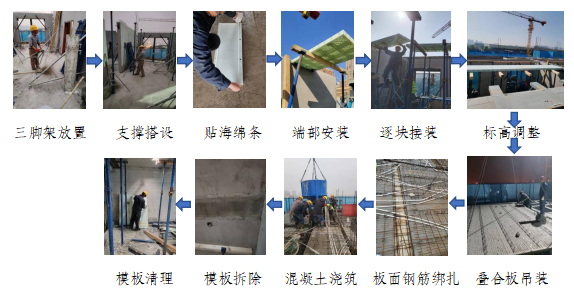

The whole process of real-time installation and dismantling process of horizontal plastic formwork on site of Building 3 of Yungu Jiayuan Project is as follows:

Figure 5 The whole process of horizontal formwork installation and dismantling

Figure 5 The whole process of horizontal formwork installation and dismantlingThe practical application of the horizontal plastic formwork in Building 3 of Yungu Jiayuan Project is as follows:

Fig. 6 Sensory effect of horizontal formwork (left) installation and demoulding (right).

The application of plastic formwork in the Yungu Jiayuan project for the first time has attracted extensive attention from industry experts, technicians and engineers. When it was installed for the first time, it was perfectly integrated with vertical components because of its simple construction process, low material loss, fast installation speed, and perfect combination with vertical components. It has won unanimous praise from the on-site observers, and they all said that the technical advantages of plastic formwork are very obvious in the node construction link in the prefabricated industry. The successful application of plastic formwork in Yungu Jiayuan project provides favorable technical conditions for the construction of SPCS cavity wall system of Sany Construction, and also lays a solid practical foundation for the promotion and application of vertical cavity wall in Hunan.

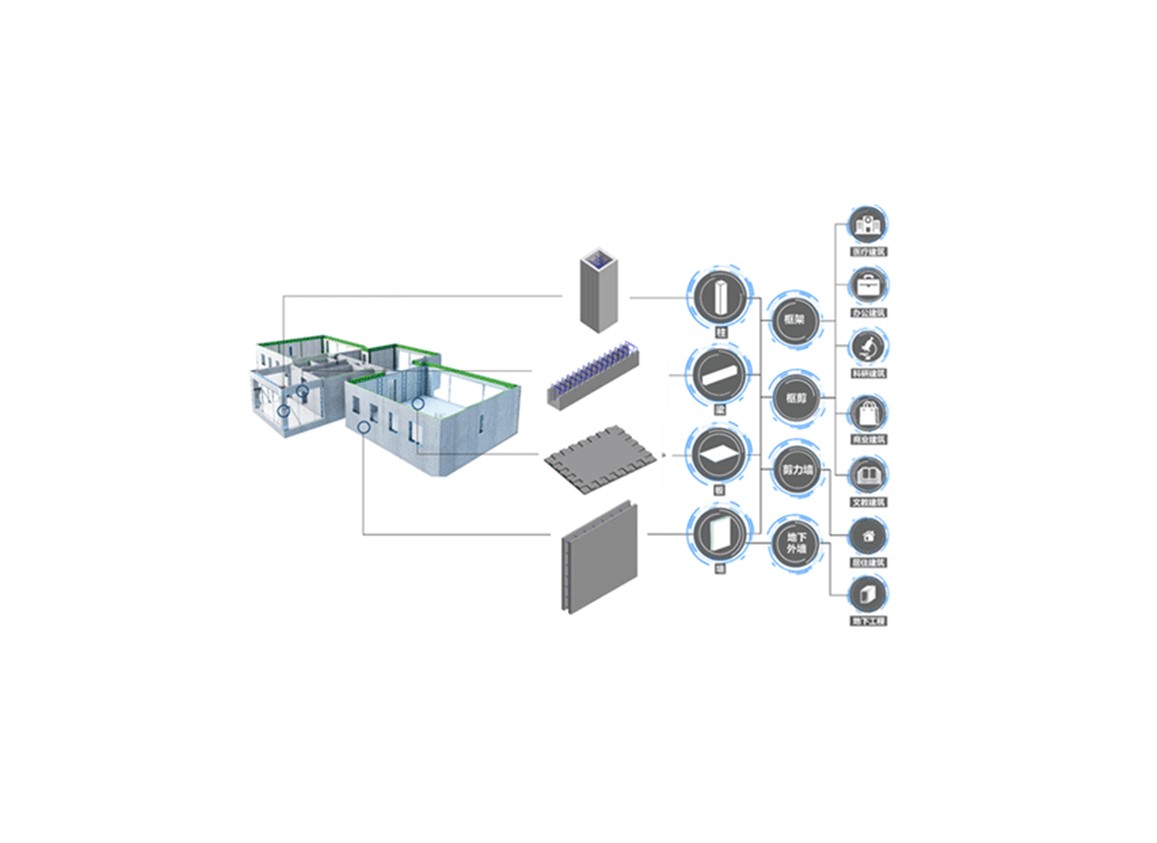

SPCS structural system

Structural standardsRecommended products

Next article:Warmly celebrate the successful delivery of the complete fracturing unit of Jinshi Engineering

0 comments

Related testimonials

Build the Greater Bay Area together|Sany rotary excavator group is in full swing to create a Shenzhen skyline

2025.06.26

Su Chao & Sany Dream Linkage, Exclusive Benefits Revealed!

2025.06.26

Sany Heavy Machinery's first overseas factory localized supply chain return training ended successfully!

2025.06.26

0 comments