Good news | Congratulations on the successful delivery of the second phase of the PC production line project in Henan Green Building

2022.04.12

Trinity Construction

Recently, Henan Green Building Integration Technology Co., Ltd. (hereinafter referred to as Henan Green Building), a wholly-owned subsidiary of Henan Seiko Green Building Technology Industrial Park Co., Ltd., successfully delivered the second PC production line purchased by Sany Construction. As a strategic partner of Sany, Henan Precision has purchased two PC integrated lines, an ALC production line, a set of double 180 commercial mixing stations, and 10 sets in SanyMixer trucksAs well as 2 loaders and other products, the two sides will work together in construction industrialization to promote the high-quality development of prefabricated buildings in Henan.

The first PC production line of Henan Green Building has been put into operation in 2021, and the second PC production line put into operation this time will have an annual production capacity of 100,000 cubic meters. Under the condition that the Sany professional installation team worked overtime and took into account the quality assurance, the installation and delivery of the equipment of the second phase of the PC production line was shortened by 42% compared with the original schedule, and the installation efficiency was the highest in the industry. At the project site, representatives of Sany Construction Engineering and Henan Lvzhu customers pulled up the banner of "Congratulations to Henan Lvzhu Integrated Technology Co., Ltd. on the delivery of the second phase of the PC production line project and the wide progress of financial resources", and took a group photo.

In order to help customers put into production as soon as possible, Sany Construction provides customers with nanny services in the whole process of pre-sale, in-sale and after-sale with the standard of turnkey project. From factory planning, process design, equipment selection, production line in-depth design, equipment manufacturing, delivery management, installation and commissioning to quality assurance inspection, every link is meticulous and strives for perfection to ensure perfect delivery for customers.

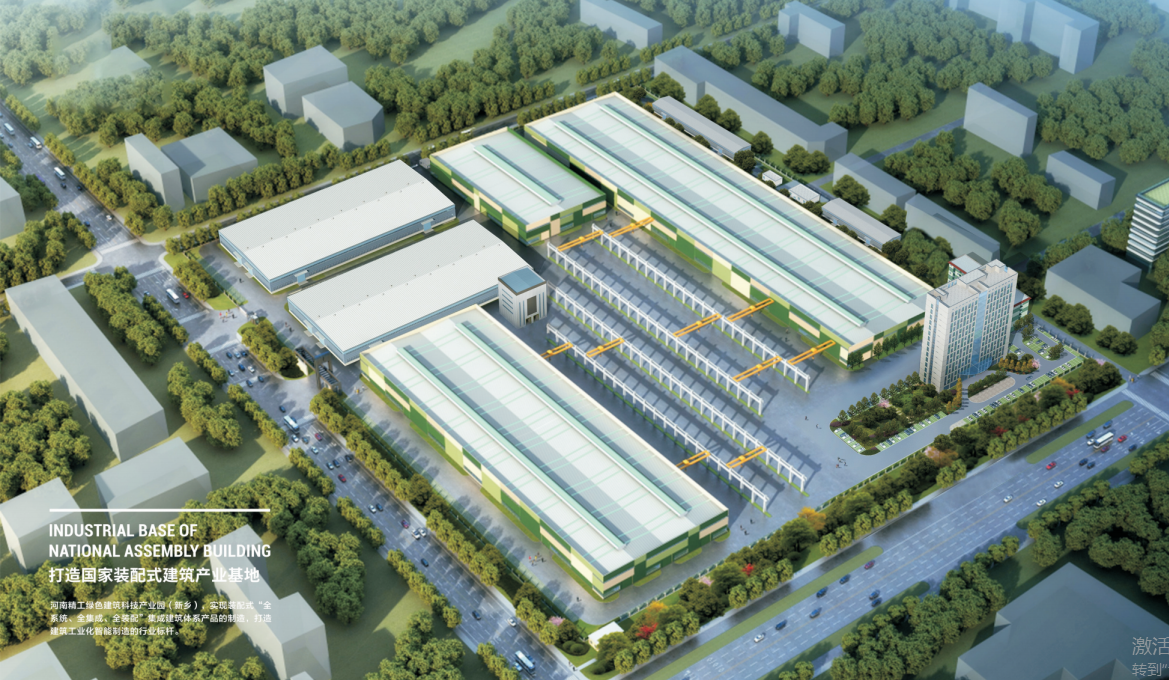

Henan Seiko Green Building Technology Industrial Park Co., Ltd. (hereinafter referred to as "Henan Seiko") was established on May 8, 2018, jointly funded by Zhejiang Seiko Group, Henan Green Industry Cluster Development and Investment Co., Ltd., and Xinxiang Muye Development Management Co., Ltd., covering an area of 200 acres.

The company's business covers prefabricated building design, parts and components production, general contracting construction, etc., and can provide customers with engineering integration services for the whole life cycle of integrated buildings.

The prefabricated building industry base in Henan Province includes steel structure workshop, PC concrete prefabricated production workshop, commercial concrete station, etc. Among them, the steel structure workshop has 4 steel structure intelligent production lines, intelligent robot welding, high-power laser cutting machines and other advanced equipment, with an annual production of about 80,000 tons of steel structure accessories. There are 3 PC intelligent production lines in the PC concrete precast production workshop, with a high degree of automation, and the annual production of prefabricated components is about 100,000 cubic meters; High-performance autoclaved aerated concrete (ALC) integrated production workshop, with an annual production capacity of 300,000 cubic meters of ALC slats. There is also a commercial concrete station with an annual output of one million cubic meters.

The company's business covers prefabricated building design, parts and components production, general contracting construction, etc., and can provide customers with engineering integration services for the whole life cycle of integrated buildings.

The prefabricated building industry base in Henan Province includes steel structure workshop, PC concrete prefabricated production workshop, commercial concrete station, etc. Among them, the steel structure workshop has 4 steel structure intelligent production lines, intelligent robot welding, high-power laser cutting machines and other advanced equipment, with an annual production of about 80,000 tons of steel structure accessories. There are 3 PC intelligent production lines in the PC concrete precast production workshop, with a high degree of automation, and the annual production of prefabricated components is about 100,000 cubic meters; High-performance autoclaved aerated concrete (ALC) integrated production workshop, with an annual production capacity of 300,000 cubic meters of ALC slats. There is also a commercial concrete station with an annual output of one million cubic meters.

Henan Green Building Integration Technology Co., Ltd. is a wholly-owned subsidiary of Henan Seiko, with the second-level qualification of general contracting, a first-class construction management team, mature prefabricated building project management experience and industry-leading prefabricated building technology - high-rise steel-concrete hybrid structure technology, which won the first prize of the National Science and Technology Progress Award at the end of 2019. The company's self-developed green building PSC integrated residential products can realize the whole system, full integration and full assembly of "structure + floor + exterior wall + interior wall + equipment + interior decoration", with an overall assembly rate of 70%~95%, which can effectively meet customers' needs for waterproof, sound insulation, energy saving and other performance of prefabricated buildings, and provide customers with safer and more comfortable high-quality residential products. It can undertake various large and medium-sized prefabricated building construction projects such as residences, hospitals, schools, venues, apartments, etc.

Henan Seiko attaches great importance to scientific and technological innovation, and at present, it has established close school-enterprise cooperation with Zhengzhou University and Xinxiang Vocational and Technical College, and jointly built Zhengzhou University Green Building R&D Center, Postdoctoral Research Station, Internship Training and Teaching Base, Xinxiang Vocational and Technical College Industry-Education Integration Training Base, Teacher Enterprise Practice Station, etc., to carry out in-depth exchanges and cooperation with colleges and universities on talents and technology. In the future, the company will carry out more comprehensive and in-depth cooperation with colleges and universities in the research and development of prefabricated building materials, technological innovation, and talent training, so as to further promote the rapid development of prefabricated building products and technologies, and improve the core competitiveness of Henan Seiko. Henan Jinggong will continue to adhere to the principle of "working hard and turning the impossible into possible; Treat people sincerely, move yourself to move others", and work together to build Henan Seiko into a benchmark in the prefabricated building industry!

Mixer truck SY412C-8H( VI.)LNG

Mixer trucksRecommended products

SY412C-8H( Ⅵ )LNG

Mixer truck SY412C-8H( VI.)LNGRelated testimonials

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

Deepening strategic cooperation and jointly expanding the Southeast Asian market -- Sany Group successfully signed a strategic cooperation agreement with well-known enterprises in Southeast Asia

2025.06.20

0 comments