The hydraulic system must not be mixed with air!

2022.10.14

Sany crane

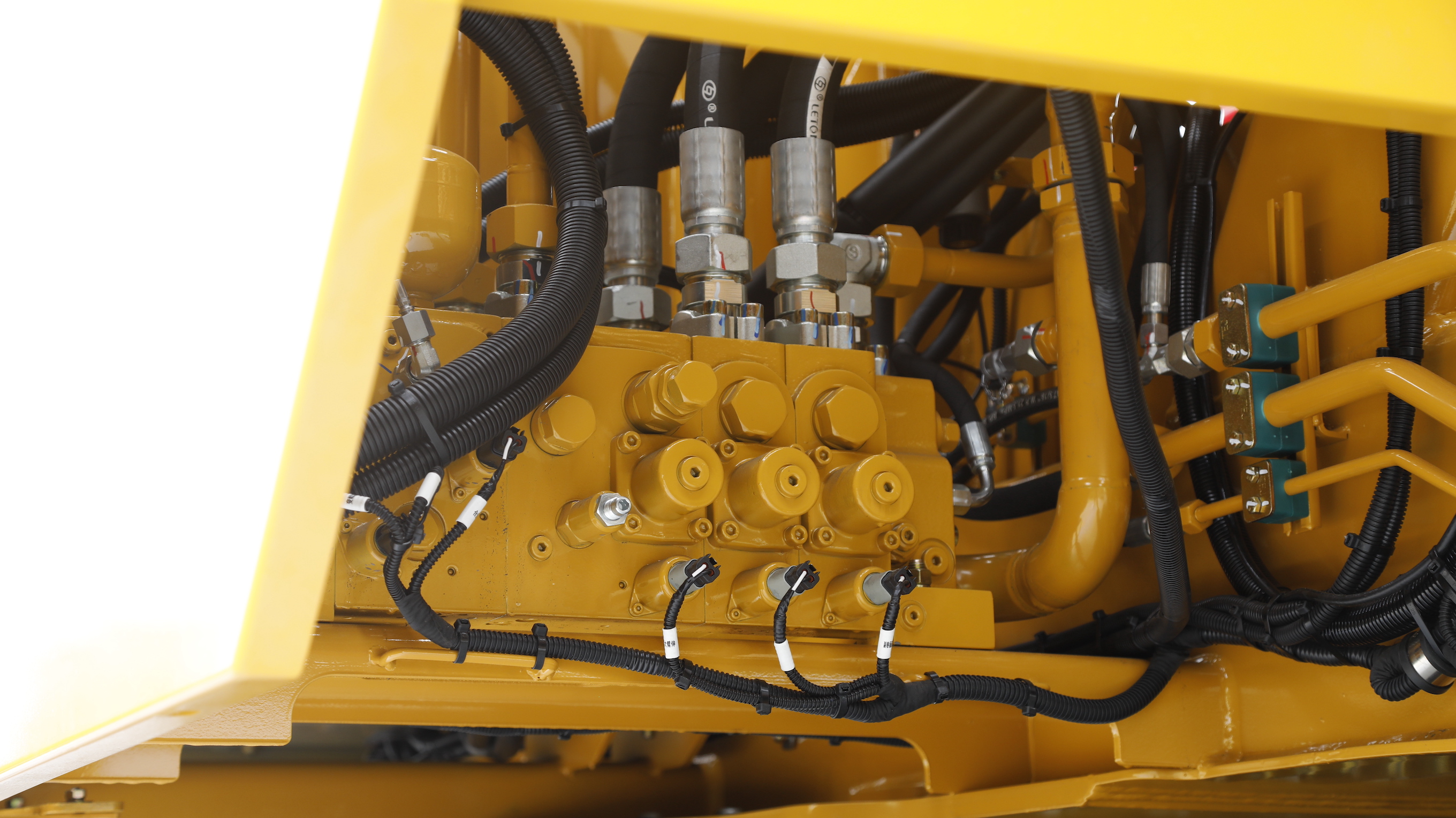

In the process of energy and signal transmission of hydraulic system, hydraulic oil is required to have good stiffness and continuity, if the hydraulic system is mixed with air, it will lose its inherent stiffness and continuity, and the stability and reliability of the hydraulic system can not be guaranteed.

When the hydraulic system is mixed with air, it will cause the following 5 hazards:

1. The rigidity of the hydraulic oil decreases sharply, resulting in the slower response of the hydraulic system and the reduction of efficiency, resulting in crawling and vibration of the actuator.

2. Air bubbles will cause the inability to form an oil film between the moving parts, resulting in poor lubrication and aggravating the wear of hydraulic components.

3. The air contains a certain amount of oxygen, which will accelerate the oxidation of hydraulic oil and system components.

4. After the bubble is pressurized, it can produce high temperature, which will promote the heating of the hydraulic oil.

5. The pressure impact generated by the bursting of the bubble after high pressure will cause cavitation of the hydraulic components.

The above 5 hazards can cause hydraulic system failure and shorten the service life of hydraulic components.In order to prevent air from entering the hydraulic system, the following precautions need to be taken:

1. If air bubbles are formed due to carelessness during refueling, they are brought into the tank and mixed into the system. Special components should be set up in the fuel tank to reduce the generation of air bubbles in the system. A partition should be set between the oil return pipe and the suction port of the hydraulic pump, and an air bubble separation net should be set above the suction pipe, which can separate about 90% of the air bubbles.

2. Air is inhaled due to loose joints or damaged oil seals and sealing rings. The hydraulic system should have good sealing, and the joints should be firmly fixed, and ensure that the fuel tank is well sealed, so as to prevent outside air from entering and polluting the system.

3. The suction pipeline and the pipeline connecting the system are worn through, abrased or corroded, so that air enters. The structure of the hydraulic system should be reasonably designed to rationalize the layout of the pipeline; It is necessary to keep the pipeline clean and reduce external corrosion.

4. Make sure that the hydraulic oil level in the hydraulic oil tank is higher than the return oil level, if the oil return level is higher than the hydraulic oil level in the oil tank, a large amount of air will be mixed. Therefore, the hydraulic oil in the oil tank should not be lower than the lower graduation line, and it should be in the middle position as the best.

5. After replacing the hydraulic parts, open the exhaust port of the parts, such as the hydraulic main pump, you can choose an oil port at the highest place to open, and add hydraulic oil for exhaust.

6. The breathing valve installed on the hydraulic tank cover should be checked and cleaned regularly. Avoid the breathing valve blocking the oil passage due to dust, affecting the air discharge of the hydraulic oil tank.

If you have other maintenance-related questions, you are welcome to leave a message in the comment area.

Related testimonials

Car report: Sansan Shoutai 2025 750 tons all-ground first-hand evaluation: loose master, return to the cost of a sharp weapon

2025.05.06

Wind power sharps hoisting new peak SCC18000TM-8 participated in the construction of the country's first 185m mountain mixed tower wind power construction

2025.05.01

Sany wind turbine + Sany main crane, independently supporting the challenge of 185m the country's highest mountain mixed tower wind power

2025.05.01

0 comments