Shock! The world's largest span up-bearing steel tube concrete arch bridge is escorted by Sany equipment!

2022.10.20

Trinity Pumping

The surging Wujiang flows eastward, and the wall rock narrow road creates a miracle.

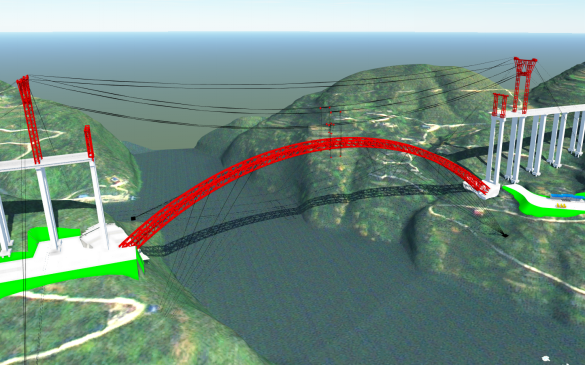

On the Wujiang River, a long rainbow flies in the trenches. Two red towers stand by the river, and a curved steel arch spans the natural danger, outlining a magnificent figure, which is particularly eye-catching.

This is the Wujiang Bridge of Guizhou Deyu Expressway under construction, in which the busy figure of Sany concrete equipment has become a beautiful scenery in the construction site.

With a total length of 1,834 meters, the Wujiang Bridge is an important control project of the Deyu Expressway and the world's largest span up-bearing steel tube concrete arch bridge. Its main span is 504 meters, which is 4 meters longer than the diameter of the "Sky Eye", and the top-bearing steel tube concrete process integrates cable-stayed bridges, suspension bridges and other complex processes, with new technology, high precision, difficult control, and the construction difficulty is at the forefront of the same type of bridge in the world.

The project is located at the junction of Fenggang, Shiqian and Sinan counties in Guizhou, and since the start of construction, it has faced many difficulties such as difficulty in the construction of side roads, difficulty in concrete construction temperature control, rainy weather and epidemic prevention and control for many days, which seriously affect the construction progress of the project. Since its entry in early September, Sany pump truck has perfectly adapted to the construction site environment with its efficient, safe and reliable product performance, providing a strong guarantee for the high-quality, safe and efficient construction of the bridge, and pressing the "fast forward button" for the construction of the Deyu Expressway.

The Wujiang Bridge adopts the pumping jacking method of conveying pumping, from the arch foot to the vault, according to the designed horizontal bridge infusion sequence and the longitudinal bridge to the "three-stage relay infusion method". Three pipes are arranged on both sides of the bridge, and both sides of the bridge need to be poured continuously at the same time each time, without any deviation, let alone failure.

In order to ensure that the project progresses as scheduled, Sany pumped 3 28 megapascal tractor pumps and one 28 megapascal pumpOn-board pumpsIt has become the main force of this pumping task, basically maintaining a 24-hour uninterrupted working state, and the single pouring of concrete in a single pipe can reach up to 800 square meters.

Zhu Wei, project leader of Hunan Sanjing Zhongbang Co., Ltd., who undertook this project, said: "The whole project is technically complex, the construction volume is large, difficult and the construction period is tight, coupled with its very strict standards and requirements for construction efficiency and quality, and the concrete construction of most of our high-rise buildings here is basically all Sany equipment, so we still chose Sany equipment this time." ”

The pouring task is tight and difficult, and the equipment is constructed 24 hours a day, which is a great challenge for the pump truck. "The quality of the equipment pumped by Sany is really reliable, adaptable, and the efficiency is not to be said, and the performance, durability rate, and failure rate are also very advantageous, and the performance is very good." Mr. Zhu, the person in charge, said with deep emotion.

In this construction, Sany equipment met the strict conditions of construction with consistent stability and safety, and won high recognition from the project party for its outstanding performance.

As the world's largest span top-bearing steel tube concrete arch bridge, the Guizhou Deyu Expressway Wujiang Bridge is technically difficult and a great challenge to the construction team and equipment performance.

In order to ensure the construction period and construction quality, Sany staff escorted all the way, followed up the progress of the project in real time, dispatched technicians to provide on-site guidance as soon as possible, and the service personnel would also regularly go to the project site to check the operation of the equipment, ensuring the smooth progress of the project, and interpreting the service concept of "exhausting all means to make Sany service unrepeatable" with actions.

Deyu Expressway is the only highway project in Guizhou Province selected as the first batch of demonstration projects of the Ministry of Transport to create demonstration projects of the "Ping An Centennial Quality Project", and has entered the sprint stage of completion and opening to traffic on schedule, and the Wujiang Bridge is one of the key control projects.

It is reported that after the completion of the Wujiang Bridge and the opening of the Deyu Expressway, it will form a composite interchange with the Hangrui Expressway and the Yande Expressway, which is of great significance for promoting the construction of a demonstration province in the western part of Guizhou's transportation power, and promoting the upgrading of industrial structure, resource development and utilization, and the development of the tourism industry along the line.

Sany will work together with all parties to strive for the early completion of the bridge and the early opening of the highway! And continue to contribute to the promotion of national development and the rejuvenation of Made in China!

Vehicle Pump SY5145THBF-9025C -10S

On-board pumpsRecommended products

SY5145THBF-9025C-10S

Vehicle Pump SY5145THBF-9025C -10SRelated recommendations

CCTV-2 focuses on Sany heavy trucks New energy heavy trucks grow in both domestic and overseas markets

2025.10.29

Sany Construction Miluo Factory-1# Hard-core "intelligent manufacturing" of the plant

2025.10.29

CCTV once again focused on Sany Renewable Energy, and the "Lighthouse Factory" lit up the road to lean manufacturing

2025.10.29

0 comments