Secret weapon! The strongest brain of the mixing plant - Sany C10 intelligent control system makes your operation so easy!

2023.02.10

Trinity Pumping

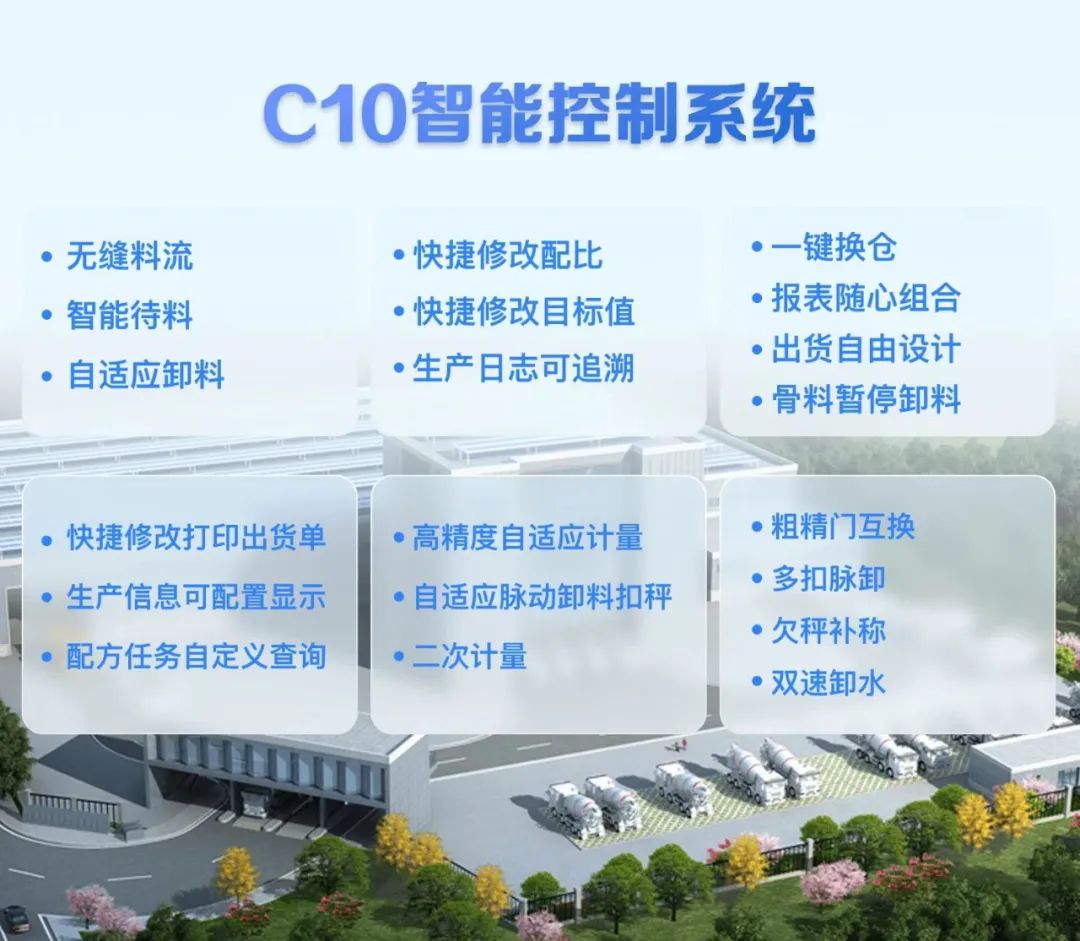

With more than 20 years of technology precipitation + 3 years of intelligent technological innovation research, Sany Heavy Industry has launched a new generation of C10 mixing plant control system, more than 20 technological innovations, supporting intelligent brain control center, independent learning and iterative production control parameters, and is your intimate assistant in production.

What is the difference between Sany C10 intelligent control system?

Minimalist experience :The new user experience adopts a flat design, removes redundant and complicated decorative effects, highlights the theme content, adopts eye-protecting color matching, reduces visual fatigue, provides a variety of quick operations, supports historical input retrieval, and is more convenient to operate.

New intelligent control technology:24 new functions have been added, fully covering the existing functions of similar products on the market, and a number of Sany characteristic functions (high-precision parameter-free production, multi-level screening of reports, flexible customization of shipping orders/reports, quick warehouse changes, operation log traceback, etc.), accurate data statistics, more stable and smoother software operation, achieving efficiency ↑30%, labor cost ↓50%, comprehensive cost ↓10%.

Carry out comprehensive upgrades for the "five major problems"

More accurate measurement :In view of a series of measurement pain points such as uneven raw material fluidity, difficulty in mastering the setting of measurement parameters, large scales and small materials, difficulty in meeting the accuracy standard, and inability to accurately supplement the scale, Sany C10 intelligent control system prescribes the right medicine, and independently develops high-precision adaptive measurement technology, adaptive pulsating discharge buckle scale technology, secondary metering technology, and secondary discharge technology to improve the measurement accuracy of the mixing plant in an all-round way.

1) Measurement accuracy is increased by 1 times: the error of a single disk <1%(行业±2% ),达标率="">is 95%;

2) Large scales can be measured in small sizes, and the lower limit of measurement reaches 10% of the range;

3) The error can be set, -1%~1%, and the measurement accuracy can be adjusted;

More efficient production :In view of the problem that poor raw material blanking affects efficiency, Sany C10 intelligent control system develops advanced technologies such as weighing after unloading, seamless material flow, intelligent waiting, and adaptive discharge parameters, intelligently identifying various production conditions, automatically adjusting the metering scale to open the door for discharging, and realize the seamless material flow transportation of aggregates, further improving production efficiency on the basis of ensuring production accuracy.

Easier control:In order to improve the user experience, the C10 intelligent control system operating system has added a number of control technologies: parameter adaptive technology, report combination at will, a variety of quick functions, etc. (quick warehouse change, one-click effect, automatic completion of silo switching, to ensure accurate recording of production consumption) operation is so easy!

The interface is more technological :The main promotion is the technology blue color scheme, the overall layout and installation function is uniformly partitioned, the interface is clean and tidy, highlighting the high-end temperament of the system, and supports 4 skin switching.

The software is smoother :It has been upgraded from three aspects: database structure, software architecture, and communication mechanism, making the control response faster, the system more stable, and the operation smoother.

0 comments