The first project in Fengtai District, Beijing to adopt the SPCS system: the first crane of the Longhu East Riverside Project was successfully completed!

2023.02.22

Trinity Construction

On February 20, 2023, the good news of early spring came: with the installation of the last prefabricated wallboard in place, the hoisting of the first section of SPCS prefabricated cavity wall of the Longhu Dongheyan project in Fengtai, Beijing was successfully completed.

The East River Along Project is jointly developed by Longfor Group and China Construction Real Estate, and constructed by Beijing Construction Engineering Construction Co., Ltd.Trinity ConstructionThe company provides prefabricated solutions, which is the first project in Fengtai District, Beijing to adopt the SPCS system, which is a milestone for the further improvement of the prefabricated building market in Fengtai District. The successful completion of the first crane has been unanimously recognized and praised by the owner, the general contractor and the construction team, reflecting the advantages of the SPCS system.

The total construction area of the Dongheyan project is 123,763.97 square meters, the above-ground construction area is 74,646 square meters, the underground construction area is 49,117.97 square meters, and the seismic fortification intensity is 8 degrees. The project has a total of 19 single buildings, with 8-10 floors and a maximum building height of 32.25m, all of which adopt SPCS system.

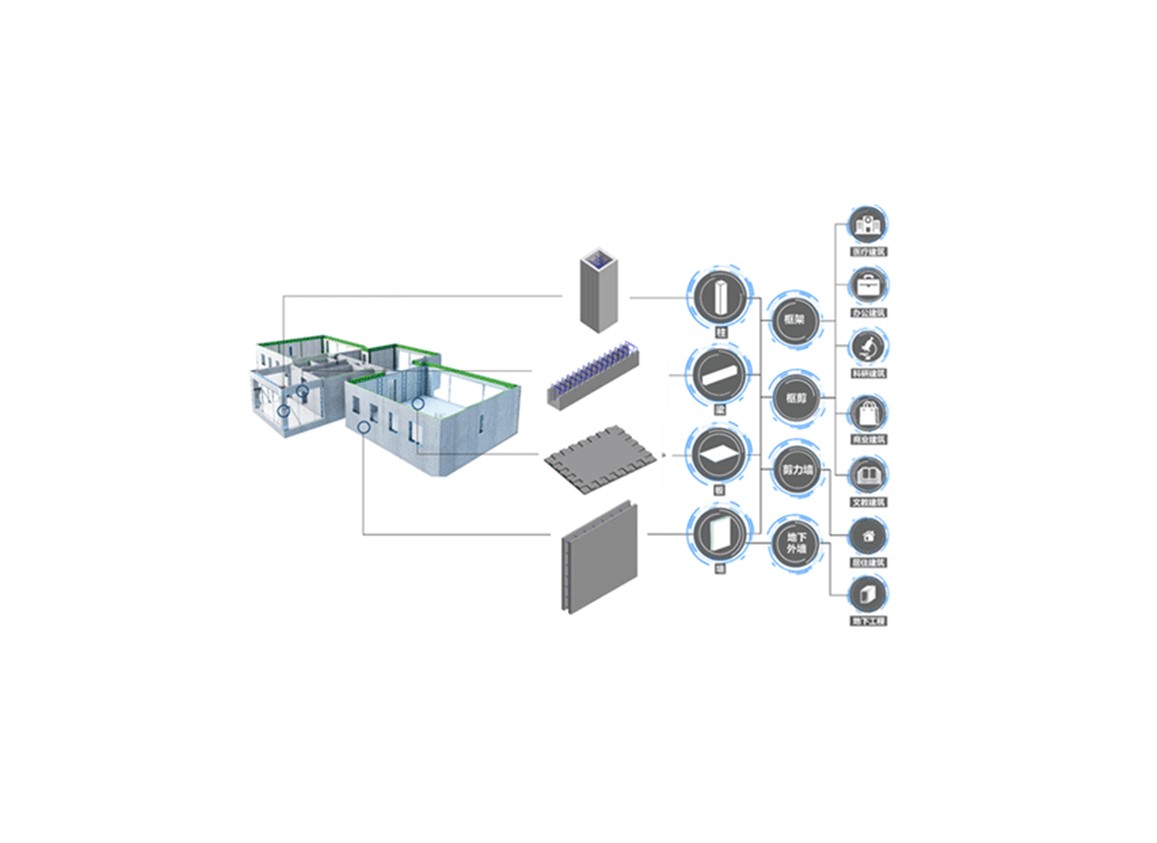

The project will use prefabricated laminated floor slabs, prefabricated air-conditioning panels, prefabricated staircases, SPCS cavity walls and other components, and the assembly rate will reach 60%. The application of a variety of prefabricated components reflects the high degree of industrialization of the SPCS system, and also shows the many achievements of Sany Construction Engineering in new technologies, new materials, new processes and new equipment.

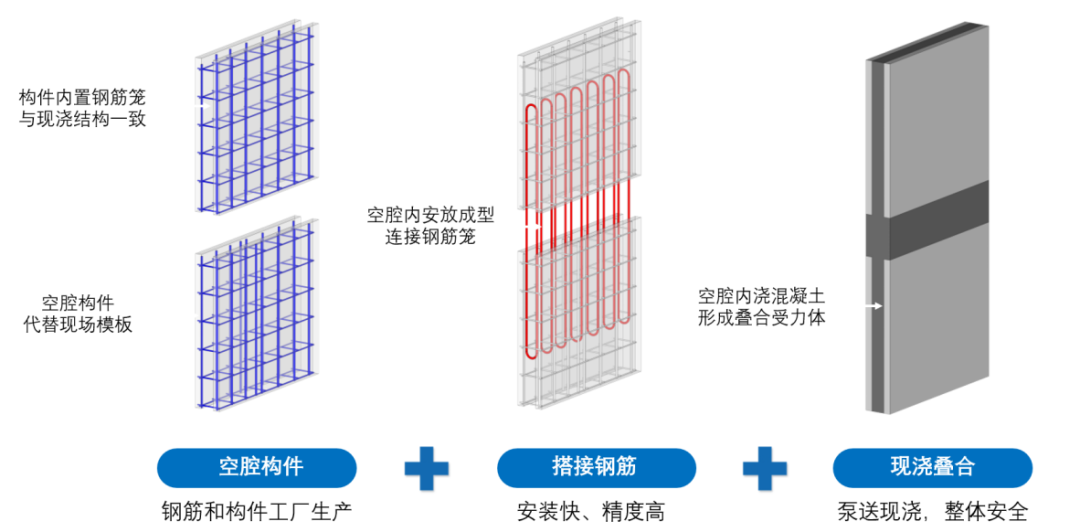

The construction process of SPCS structural system is streamlined and standardized, and through the comprehensive penetration of the technical route of "cavity wall column + equivalent isomerism + mold technology + in-plane operation", "full prefabrication of walls, columns, beams and slabs, and full assembly of aboveground and underground" can be realized.

During the first hoisting period, through the on-site guidance of the construction empowerment personnel of Sany Construction Engineering, the first hoisting worker can hoist a wallboard in less than 10 minutes, which greatly improves the installation efficiency of components, accelerates the construction progress, and improves the construction efficiency; The assembled integral superimposed concrete structure form of "cavity lap and post-casting" also makes the overall safety of the structure higher and the waterproof performance better, so as to achieve the equivalent cast-in-place effect in the real sense.

At present, the East River along the project has officially entered the stage of big trunk and fast development, and the multiple advantages of Sany Construction's SPCS structural system will inject strong strength into the realization of the overall goal of the project.

Through the implementation of one project after another, the SPCS structural system has been widely recognized by social colleagues and industry experts, and it is believed that the SPCS system will be promoted and applied in more and more places in the future, and the SPCS inside will be truly realized - prefabricated buildings, with low structural safety costs; Build and enjoy cloud construction, green and low-carbon, fast and saving! Down-to-earth, unremitting and long-term work, while committed to "industrializing construction", Sany Construction is willing to work with all construction enterprises to build an open and collaborative new ecology of intelligent construction.

SPCS structural system

Structural standardsRecommended products

Related testimonials

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Three records! The Beijing-Harbin Expressway Sany unmanned paving machine group has been under continuous construction for more than 480 hours

2025.06.20

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

0 comments