Well-known construction experts from Hainan Province & Beijing Municipality successfully carried out the SPCS technical exchange meeting in Sany Construction Engineering and gained a lot!

2023.03.20

Trinity Construction

In recent years, Hainan Province attaches great importance to and vigorously develops the prefabricated building industry. In 2020, the Hainan Provincial Government included prefabricated buildings as one of the four landmark projects for Hainan to build a national ecological civilization pilot zone. The development of prefabricated buildings is not only an important measure for Hainan Province to promote the transformation and upgrading of the construction industry, but also an important support for Hainan Province to achieve carbon peak and carbon neutrality.

In order to learn from each other and exchange valuable experience in prefabricated buildings and promote the development of intelligent construction in Hainan, Duan Xiaonong, chairman of the Hainan Civil Engineering and Architecture Society, and other Hainan construction experts visited Sany Construction on March 18. The expert group visited the Beijing project under construction and the Beijing PC factory, and conducted in-depth exchanges with Beijing experts such as Huo Wenying, chief engineer of China Architectural Design and Research Institute, on the development of prefabricated buildings and the SPCS system of Sany Construction. Xu Wenhao, deputy general manager of Sany Construction Engineering, Ma Yunfei, chief engineer, Mao Daoqin, general manager of South China Region, and other company leaders received the reception.

Hainan experts first came to visit the Asuwei Directional Resettlement Housing Project in Baishan Town, Changping District. The SPCS application area of the project is 92,600 square meters, with a total of 10 prefabricated buildings, and the component type is mainly prefabricated cavity walls, with an assembly rate of 51%.

Afterwards, he visited the production site of Sany Construction Engineering Beijing PC Factory, and observed the whole process of producing a high-quality prefabricated component by various station equipment such as mold table cleaning, automatic marking, automatic mold layout, and automatic flipping, as well as how the central control room uses "platform plan collaboration, online transmission of design data, and digitally driven intelligent equipment" to produce components.

In the afternoon, Hainan experts came to visit the Longfor Yunjing project located in Shahe Town, Changping District, which is the first large-scale application of SPCS commercial housing landing project in Beijing, which is the 5G lighthouse construction site of Sany Construction, using SPCS cavity prefabricated walls, superimposed floor slabs, prefabricated stairs and other prefabricated components, with an assembly rate of more than 50%.

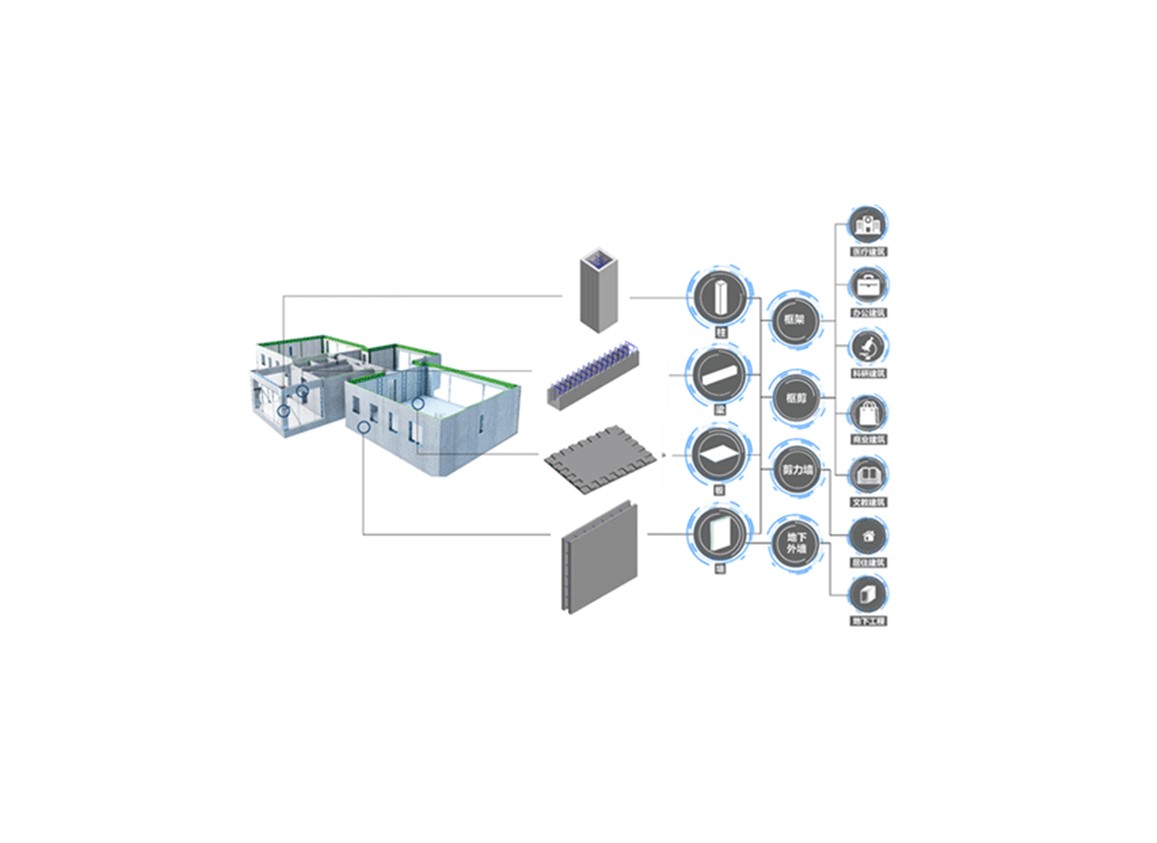

During the discussion, Xu Wenhao, deputy general manager of Sany Construction Engineering, first extended a warm welcome to the experts who came from afar, and introduced that Sany Construction Engineering is committed to "industrialization of construction", relying on the advantages of the group's "top three global construction machinery" and the industrial Internet of Things, focusing on prefabricated concrete buildings, through the research and development and basic research of intelligent equipment and structural technology from 2013 to 2017, and the standard construction and project engineering practice from 2018 to 2019, to create a "cross-shaped" Sany Building Industrialization System - SPCS Among them, "one vertical" is the core technology route (cavity wall column + equivalent heterogeneous + mold technology + in-plane operation), and "one horizontal" is "5231" hard technology (5 types of equipment,Category 2 standards, 3 types of software, 1 platform).

Duan Xiaonong, chairman of the Hainan Civil Engineering and Architecture Society and chief engineer of Yuanzheng Architectural Design Consulting Co., Ltd., said that he had a certain understanding of SPCS structural technology before, and that the road of building industrialization in Hainan was still in the process of exploration, and it needed to go through a lot of experimental verification and in-depth discussion.

Zhang Airong, vice president of Sany Construction Engineering Architectural Design and Research Institute, introduced the SPCS structural technology system in detail. The system has the advantages of "high building quality, good waterproof performance, and light weight of components", and has successively formed a number of technical standards in recent years, and has built a perfect closed loop of design-production-construction-acceptance standards. At present, SPCS structural technology has been popularized and applied in many provinces and cities across the country, with a cumulative landing area of nearly 10 million square meters.

Li Ran, deputy director of the Prefabricated Structure System Technology Center of China Academy of Building Research, and Ren Chongcui, assistant to the dean of the Structural Institute and director of the Institute of Structures of the China Academy of Building Research, China Academy of Building Research, Science and Technology Engineering Consulting and Design Institute, systematically introduced the SPCS experimental research.

Since 2017, relevant research has been carried out on the basic theory, SPCS frame structure and SPCS shear wall structure, and the conclusion is concluded through the data and repeated verification of scientific research such as SPCS mechanical property test of superimposed beam, mechanical property and seismic performance test of superimposed column, and seismic performance test of superimposed shear wall.

After several rounds of exchanges, the expert group believes that the SPCS structural technology system has formed a complete stressed body due to the continuous pouring of concrete, and the overall structure is safe, with the same mechanical performance as the cast-in-place structure, and at the same time, the waterproof performance is good, which avoids the two major pain points of the traditional prefabricated structure safety questioning and water leakage. Experts also put forward reasonable suggestions, such as: when the size of the post-pouring section between the SPCS superimposed shear walls is less than 600, this part of the cast-in-place concrete can also be included in the calculation of the assembly rate.

In the future, Sany Construction will continue to be based on technological innovation and market demand, unswervingly increase investment in research and development, and work with the Hainan Provincial Government and colleagues in the construction industry to create a more stable and long-term win-win mechanism, so as to contribute more Sany strength to the transformation and upgrading of the construction industry in Hainan Province! Make every effort for the high-quality development of the industry and the national economy!

Members of the Hainan Expert Group:

Duan Xiaonong, Chairman of Hainan Civil Engineering and Architecture Society and Chief Engineer of Hainan Yuanzheng Architectural Design and Consulting Co., Ltd.; Zhang Ming, Chief Engineer of Hainan Baisen Architectural Design Co., Ltd.; Sun Yaodong, deputy general manager of Hainan Provincial Architectural Design and Research Institute; Li Yanjun, deputy general manager and chief structural engineer of Hainan Branch of Beijing Zhonglian Huanjianwen Architectural Design Co., Ltd.

Members of the Beijing Expert Group:

Huo Wenying, Chief Engineer of China Architectural Design and Research Institute; Li Hongqiu, Executive President and Chief Engineer of Beijing Weituo Times Architectural Design Co., Ltd.; Tian Dong, Deputy Chief Engineer of Beijing Architectural Design and Research Institute and Deputy Director of Industrialization Engineering Technology Research Center; Ren Chongcui, assistant to the dean of the Structural Institute of the China Construction Research Institute of China Construction Research Science and Technology Engineering Consulting and Design Institute, and director of the Institute of Structure; Li Ran, deputy director of the Prefabricated Structure System Technology Center of China Academy of Building Research; Tian Chunyu, deputy chief engineer of China Construction Technology Group Co., Ltd.

SPCS structural system

Structural standardsRecommended products

Related testimonials

Sany Heavy Machinery's first overseas factory localized supply chain return training ended successfully!

2025.06.26

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

0 comments