Best Practices for Building Industrialization: Shanghai SPCS Resettlement Housing Project Construction Operation "Four Days and One Floor"

2023.05.08

Trinity Construction

Recently, the affordable housing project in Xinbang Town, Songjiang District, Shanghai, which fully applies the SPCS system, has successfully completed the construction operation of the standard layer "four days and one floor" in accordance with the standard construction period template.

The Xinbang Town Affordable Housing Project has a total land area of 32,384.2 square meters, a total construction area of 102,030.72 square meters, a plot ratio of 1.996, and a building area of 64,637.46 square meters.

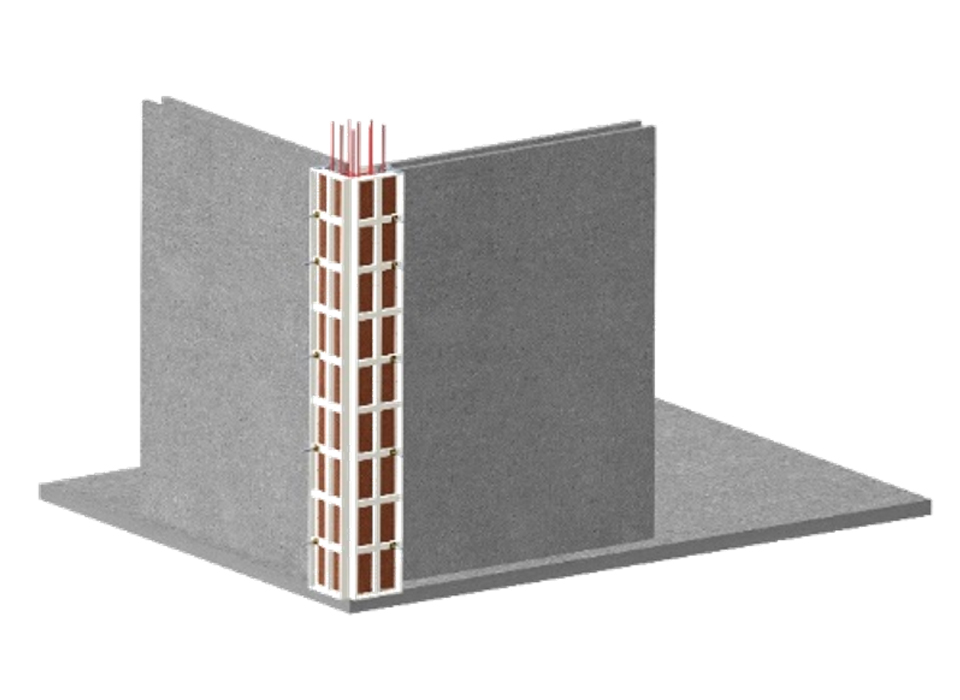

The project has a total of 12 single buildings, 17 floors above ground and 1 floor underground, and the residences of 2-12# buildings all adopt SPCS system, with a seismic fortification intensity of 7 degrees, 0.1g, and component types include SPCS cavity walls, stairs, etc.

△ Bird's-eye view rendering

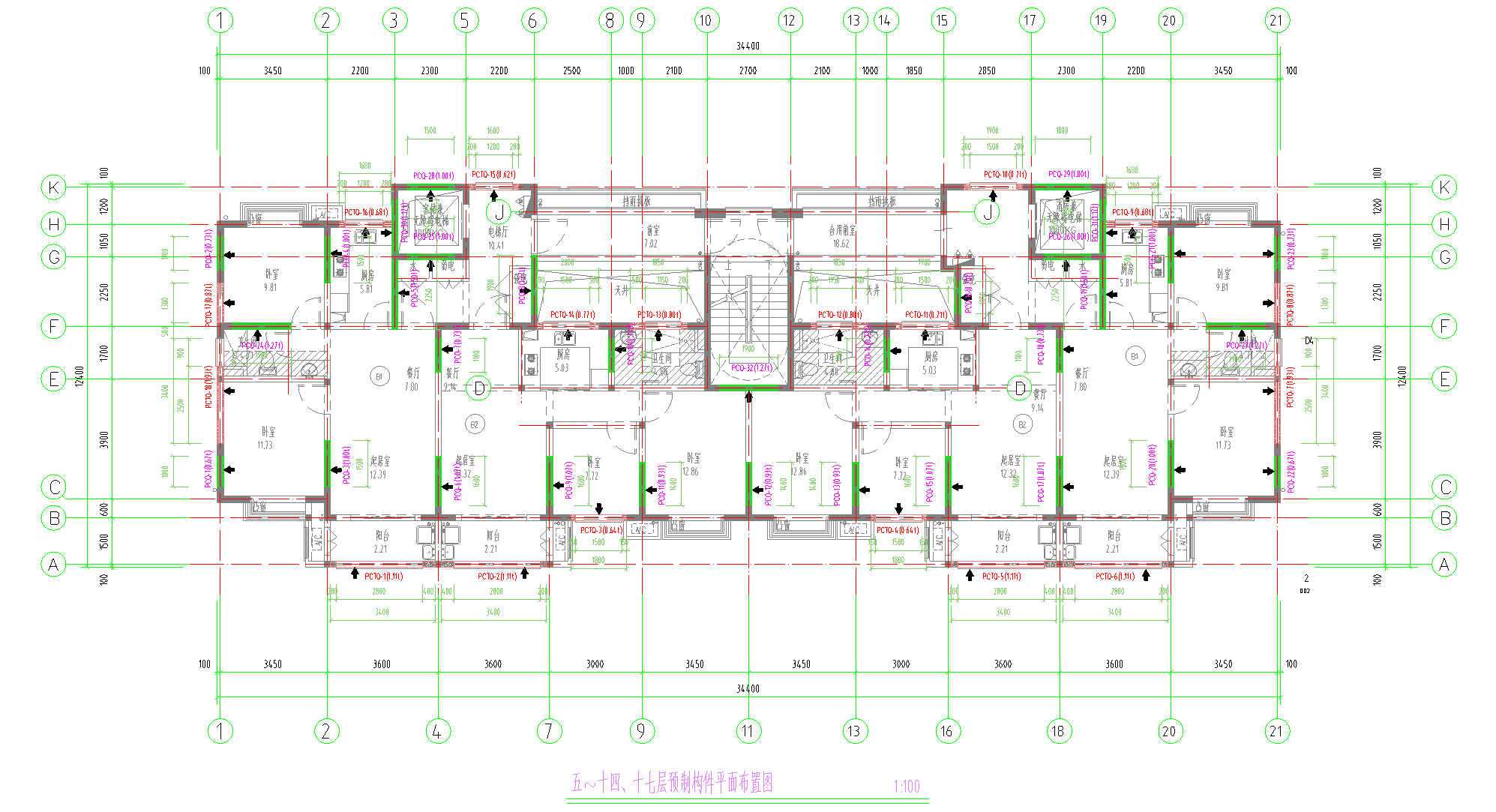

△ PC component installation floor plan

During this period, Sany Construction provided professional and perfect project implementation plans and technical assurance measures for the project party and the general contractor, and provided full empowerment and guidance to ensure that the project successfully completed the construction progress of "one floor in four days" with a total time of "33.5 hours", and the number of workers was not increased in each process in the construction process, and the advantages of "faster" SPCS system were clear at a glance.

April 27thThe first day of construction is 10 hours of work

The work starts at 6:00 on the same day and is completed at 17:00. Complete the measurement and pay-off, working face preparation, SPCS wall panel hoisting, steel bar binding and other work, including 46 SPCS wall panels, the average hoisting time of each piece is 6 minutes.

In the working face preparation stage, the wall control line is popped up on the concrete surface of the working layer according to the construction drawings; The cushion block copy test is carried out in advance, and the elevation of the cushion block is clearly marked; Use a steel tape measure to check the positioning of the reinforcement against the edge line of the wall panel, and correct the deviation that exceeds the allowable deviation to ensure that the vertical reinforcement does not affect the hoisting of the cavity wall. Doing a good job of hoisting preparation in the working face preparation stage can improve the hoisting efficiency of cavity wall.

Before the SPCS wall panel is hoisted, check the component type and number according to the hoisting plan, confirm the installation position, and mark the hoisting sequence; When hoisting, ensure that the center of gravity and the lifting point of the cavity wall are in the same vertical line, and when the cavity wall is in a vertical state, the wall is installed to avoid secondary lifting. Due to the light SPCS cavity wall component and the high fault tolerance rate of the cavity 100mm insert bar, the hoisting efficiency is far better than that of the traditional PC component (the normal operation of a tower crane is hoisted this time, and the hoisting efficiency of the cavity wall is 6 minutes per block on average).

In the steel bar binding stage, the node steel bar binding can be carried out synchronously with the cavity wall hoisting, and the cross operation can be carried out; For the installation of horizontal annular connecting bars in the cavity wall, the horizontal annular bars and the steel cage of the post-pouring node can be firmly tied with the binding wire, and at least one intersection of the ring bars can be tied. Because the SPCS cavity wall does not have reinforcement on all sides, the prefabricated cavity wall and the node reinforcement rely on the horizontal annular reinforcement to insert the cavity connection, so the node reinforcement binding can be carried out synchronously with the cavity wall hoisting or even front, which can greatly improve the efficiency and compress the construction period.

April 28thOn the second day of construction, the operation is 13 hours

The operation starts at 6:00 on the same day and completes the horizontal operation at 19:50 (other teams leave work at 17:00). finishNode templateMold matching, installation, support erection, floor formwork support, etc.

The difference between the stage of mold matching, installation, support erection, and floor formwork support of the node formwork is that the lower part of the SPCS cavity wall panel is a 50mm gap, and a special fixture is selected for plugging to ensure the pouring quality.

April 29thOn the third day of construction, 7.5 hours of operation

The operation started at 6:00 on the same day and was completed at 15:38, but due to the rain on the day, there was no homework from 9:30 to 12:00. Complete the installation of vertical formwork, water and electricity, floor reinforcement, formwork reinforcement, etc.

In the stage of hydropower installation and floor reinforcement installation, the hydropower is embedded before the steel bar binding of the working face, and the floor steel bar can be installed according to the drawing, positioned in advance, installed the steel bar and placed the oblique support anchor ring. The positioning of the reinforcement ensures precision, it is set in the center of the cavity, and after the installation is completed, the joint acceptance is carried out.

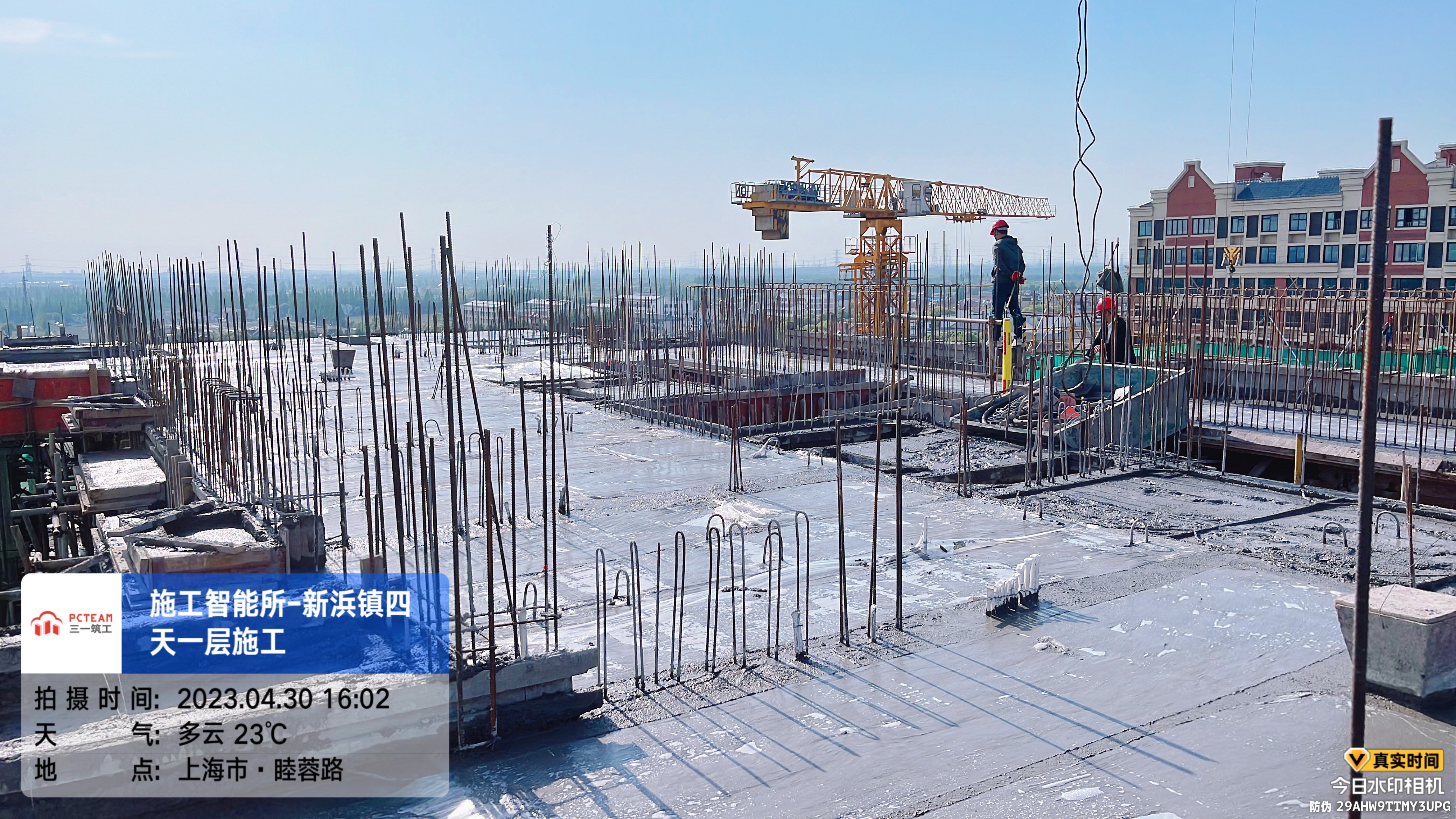

April 30thOn the fourth day of construction, 3 hours of work

The operation started at 12:00 on the same day, and the concrete pouring was completed at 15:00.

Before pouring concrete, the prefabricated components are fully watered and wetted, and the concrete is poured in layers, and the layered height should not exceed 1 meter, and the vibration is compact. Pay attention to fast plugging and slow unplugging, the time of each insertion and vibration is 20-30 seconds, the front end of the vibrating rod should be inserted into the previous layer of concrete, and the insertion depth should not be less than 50mm.

Sany Building Industrialization System Solution-SPCS adopts the technical route of "cavity wall column + equivalent heterogeneity + mold technology + in-plane operation" to solve the two major pain points of questionable structural safety and high cost, and realize the overall goal of "low structural safety cost, green and low-carbon, fast and saving" of prefabricated buildings. In this project, the application of SPCS technology route has exerted the ultimate effect, so that workers can complete the construction of one floor with only simple assembly on site, which greatly improves the construction efficiency and construction quality.

The completion of the "four-day, one-store" operation of the affordable housing project in Xinbang Town, Songjiang District, Shanghai is not only a best practice for construction industrialization, but also an important milestone in the development of China's construction industry in the direction of high quality, high efficiency, low carbon and environmental protection. Sany Construction Engineering will continue to adhere to the SPCS technical route, improve the 5231 hard technology, continuously improve the SPCS building industrialization system solution capabilities, promote the coordinated development of intelligent construction and building industrialization, and make unremitting efforts to realize the great vision of "making the world no difficult to do architecture"!

Recommended products

Related testimonials

Su Chao & Sany Dream Linkage, Exclusive Benefits Revealed!

2025.06.26

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

0 comments