Monthly output exceeded 100,000 | Sany heavy shearer helps Hamachong Coal Mine break the record again!

2023.07.14

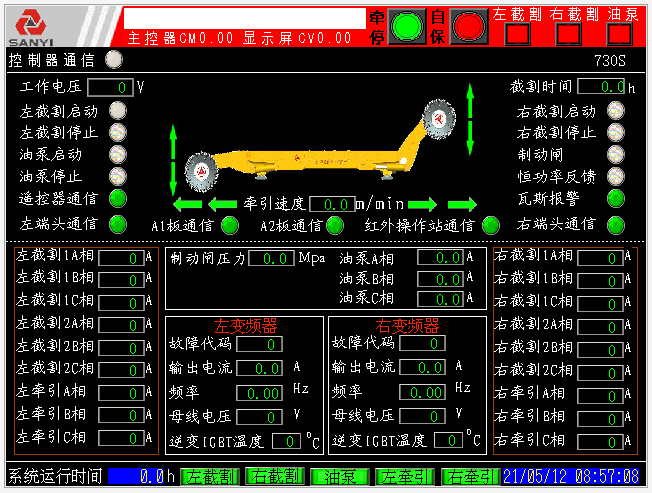

Hamachong Coal Mine is located in the Qiannan region of Guizhou Province, and as a loyal customer of Sany Heavy Equipment, it purchased complete sets of fully mechanized mining equipment from Sany Heavy Equipment in 2022. Among them MG2×160/730-WDShearersHigh production and high efficiency, no major failures since the use of the well, and the mining of the second working face was started in April this year.In order to ensure the completion of the production task, under the premise of ensuring safe production, the mine manager took the lead in holding a special meeting to refine the production organization and implement regular cycle operations.

In order to effectively reduce the failure rate of equipment, the mine insists on using the original accessories provided by Sany Heavy Equipment and meticulous maintenance. Not only that, Hamachong Coal Mine has also set up an equipment maintenance team, led by the mechanical and electrical mine manager to carry out daily maintenance of the shearer. During the equipment overhaul, the shearer shall be maintained in strict accordance with the "Shearer Maintenance Manual" provided by Sany Heavy Equipment.At the same time, Sany Heavy Equipment also provided an equipment checklist for the mine, and the cutting department, traction department, hydraulic and water system, electrical system and other parts of the shearer should be signed after maintenance, and the responsibility should be strictly implemented.

Sany Heavy MG2×160/730-WD shearer has won praise from the mine for its excellent quality and excellent after-sales service. In May, the output also reached a new high - the cumulative production of raw coal in a single month exceeded 100,000 tons, and the daily output reached a maximum of 4,000 tons.

Sany Heavy Equipment MG2×160/730-WD series shearer is a shearer with a rocker arm of double cutting motor, which is specially designed for the working face with a height of 1.4~2.5 meters, which can not only meet the mining of thin coal seams but also take into account the mining of medium and thick coal seams.At present, MG2×160/730-WD shearer has been exported to Guizhou, Yunnan, Shanxi, Shaanxi and other provinces, and the whole machine has been highly recognized by customers in terms of reliability, maintenance and advancement.

Technological advantages

- Mechanical system reliability

The research and development of new wear-resistant materials has solved the pain points of non-wear-resistant key components in the industry, and the life of key components has been greatly improved.

Guide sliding shoes: Innovative introduction of cemented carbide wear-resistant technology, anti-friction and wear-resistant, the life of guide sliding shoes can reach more than 6 months.

Internal spray: The ceramic wear-resistant technology is introduced to solve the problem of water leakage and lubricating oil contamination after the wear of the inner spray water pipe, and at the same time ensure the dust reduction effect of the spray.

Drum: a new type of alloy bean wear-resistant pick, which reduces the consumption of picks by 30% and reduces the mining cost.

Walking wheels: The walking wheels are made of deep carburizing technology, and one working face can be used without replacement.

- Hydraulic system reliability

Quantitative load sensing system: the combination of quantitative pump + load sensing multi-way valve can reduce the power loss of the system; Electronically controlled and manual dual operation modes, small size, sensitive and reliable operation.

Double pump and double circuit: the large pump is used for the height adjustment system, and the small pump is used for the braking system to ensure the reliable operation of the system.

Tubular cooler: cooled in the oil tank, takes up little space, and ensures that the oil is fully cooled.

- Mechanical system maintainability

The position of the swingarm and the traction hinge is connected by a self-lubricating bushing, which does not require oil injection.

The components inside the electric control box adopt a modular installation method, which is convenient for maintenance and repair.

The new clutch solves the problem that the clutch is inconvenient to maintain at the same time on the structure of the thin coal seam rocker arm double cutting motor, and realizes the purpose of controlling the opening and closing of the transmission mechanism on the goaf side of the rocker arm, which is convenient to use, easy to maintain, safe and reliable.

- Advanced electrical system

Perfect intelligent self-diagnosis system, with fault location and alarm prompt functions.

Black box data storage system with fault memory and query functions.

Recommended products

MG330/730-WD

Shearer MG330/730-WDNext article:Subverting the tradition, TASI personally tests to tell you how fragrant "smart climbing" is!

0 comments