Sany hydrogen refueling integrated station + hydrogen energy heavy truck | Create a zero-carbon overall solution

2023.08.10

Sany heavy truck

"The ultimate energy, the future has come" Sany's hydrogen energy overall solution has been commercialized!

Sany hydrogenation integrated station, for:Hydrogen production, storage, transportation, and fillingProvide a full set of solutions to solve the problems of high cost of hydrogen and insufficient hydrogen source in transportation scenariosHydrogen has low cost, high hydrogen production efficiency, and digital monitoringand other features.

by more than 20 years of industry experienceTOP leading talentsand 100+ top hydrogen energy R&D and process talents for structural design, electrochemical design, simulation and test testing.Build a hydrogen production system based on water electrolysis with independent intellectual property rights of Sany,Hydrogen refueling equipmentand core componentsIt has successfully laid out the whole industrial chain of green hydrogen production, storage, transportation and refueling equipment.

Hydrogen production

Alkaline water electrolysis to produce hydrogen

The maximum current density can reach 8000A/㎡

DC power consumption ≤ 4.3 kWh/Nm³

Power fluctuation range: 20~100 %

Hydrogenation

Hydrodosing pressure

The rated working pressure is 35MPa

Daily filling capacity: 500/750/1000kg/d

Maximum filling speed: 5kg/min

Filling rate: 95~100%

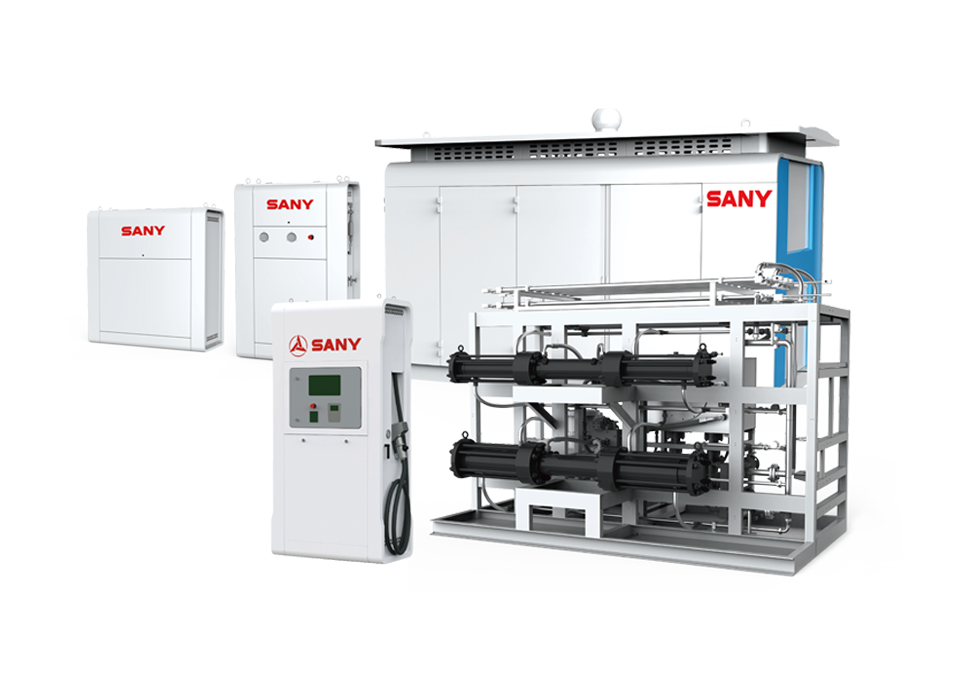

Sany provides complete sets of fixed and skid-mounted hydrogen refueling stations for customers to choose.

Stationary hydrogen refueling stations: Equipped with unloading, pressurization, storage and cooling modules, fast filling speed and high filling rate. It can realize remote filling, hydrogen metering, key equipment status monitoring, cloud computing and big data analysis functions.

Skid-mounted hydrogen refueling stationsIt integrates hydrogenation, cooling, metering, and digital control, and completes the processes of equipment manufacturing, testing, and commissioning in the factory, and the station is convenient and flexible, with high efficiency and short cycle.

The commercialization of the Sany hydrogen refueling integrated station,Realize energy supply and solve the range problem for the operation of Sany hydrogen fuel heavy trucks。

Sany hydrogen fuel heavy truck adopts a high-power permanent magnet synchronous motor with a rated power of 250kW, a maximum torque of 2400N·m, and a motor efficiency of more than 95%.Low hydrogen consumption, long battery life, light weight, weather resistance, and cool driving, with the Sany hydrogen refueling integrated station, to provide customers with a more controllable cost zero-carbon operation model.

Low hydrogen consumption

Low-speed/inverted/port and other scenarios

The economic speed is 40km/h, and the load is variable

The hydrogen consumption of the whole vehicle is less than 12kg per 100 kilometers, which is leading the industry

Long battery life

High-pressure 35MPa large-capacity hydrogen storage system, hydrogen refueling 38kg

The driving range under comprehensive working conditions at full load ≥ 340km

The constant speed is 40 km/h at full load, and the continuous driving ≥ is 450 km

Lightweight

The weight of the vehicle is only 10.7T, which is 3%+ lighter than similar products

Weather resistance

The ambient temperature is -30°C~50°C

The product has good environmental adaptability

Cool ride

12-inch central control screen + 7-inch LCD instrument

> 1.9-metre-high flat-floor cab

900mm star hotel zero-pressure sleeper

Four-airbag mount + airbag shock-absorbing seat

6-speed aluminum-shell AMT, pocket gear shift

Sany hydrogen refueling integrated station, good at reasonableThe chemical park is used to produce hydrogen from green electricity by using the nearby wind and solar resources, providing large-scale chemical hydrogen, building"Zero-carbon factory model".

Provide an overall solution with renewable energy, more controllable costs, cleaner and low-carbon:"Green electricity + water electrolysis to hydrogen + hydrogen refueling + hydrogen fuel heavy truck"to build a zero-carbon future.

0 comments