Sany Heavy Installation SV9210 vertical shaft impact crushing equipment was delivered to Hunan Huajian

2023.08.24

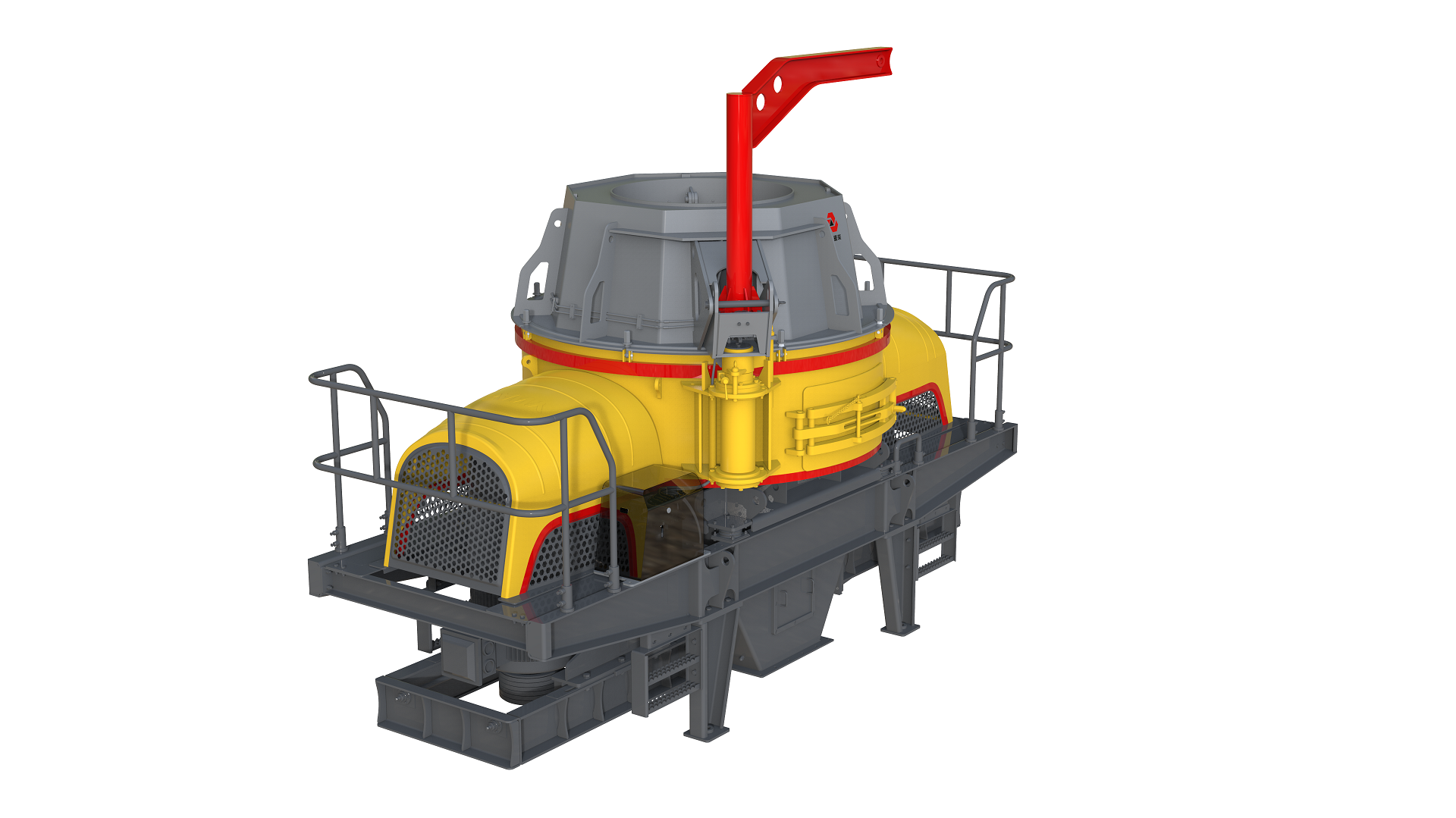

In the wave of digital transformation, Hunan Huajian New Material Technology Co., Ltd. seizes the development trend of the industry, adheres to the concept of green environmental protection, and strengthens the transformation and upgrading of digital, intelligent and automated technologies. In order to meet the needs of the construction of the "lighthouse factory", in the construction of the second phase of the company's project, Long Haiping, chairman of Hunan Huajian, chose Sany for cooperation - this month, Sany was reequipped with two unitsSV9210Vertical shaft impact crusherIt will be delivered and put into production soon.

- Proven product features——As a manufacturer of front-end crushing lines, Sany Heavy Equipment is committed to providing the best and most economical complete crushing line solutions for the industry. Adhering to the business philosophy of "all for customers, all from innovation", relying on the mature R&D system and according to the actual needs of customers, Sany Heavy Equipment has developed and manufactured environmentally friendly, energy-saving, high-yield and high-efficiency sand making equipment - SV9211 vertical shaft impact crusher, which can produce more than 150 tons of high-quality sand per hour with a single equipment, saving more than 15% of energy consumption for customers, and providing high-quality raw materials for subsequent supporting commercial mixing stations.

- A sound supporting system——At present, Heavy Equipment has 12 service branches in China, with 100% coverage of service vehicles and an average service radius of 150 kilometers. In addition, it is also equipped with high-tech modern information systems such as ECC, GCP, CSM, and 4008 dedicated line system, and has established a comprehensive and three-dimensional resource allocation service system for real-time positioning of customer equipment, service vehicles, and service engineers.

- Perfect after-sales service——Since the date of delivery of the equipment, Sany Heavy Equipment provides free after-sales service, and the newly delivered equipment is guided by the service engineer stationed in the mine, and assists in commissioning and acceptance on site to ensure the normal production of the equipment. Fulfill the 121 service commitment, set off in 1 quarter of an hour, arrive in 2 hours, and solve equipment failures within 1 day after receiving customer appeals.

Sany Heavy Duty SV series vertical shaft impact crusher is used for fine crushing operations such as sand making and shaping. It is widely used in the fields of sand and gravel aggregate production, gangue crushing and backfilling, tailings treatment, etc., with good crushing effect, excellent product particle shape, and at the same timeEnergy-saving, efficient, reliable and durable, low maintenance cost, high degree of intelligenceIts performance indicators can reach the leading level in China, providing customers with crushing equipment with ultra-high comprehensive benefits. The crushing product spectrum covers a wide range of production lines, matching all kinds of production lines, and the sand making machine has as a fine crushed productSV7210/SV8210/SV9210/SVA210 series productsto meet the needs of various production lines.

Core advantages of the product:

- Reliability: BTMCr26 is used for key castings, and UT flaw detection is used for key surfaces; The spindle is made of quenched and tempered 42CrMo forgings, and the bearing is made of SKF/FAG; The lubrication station is equipped with imported parts, the performance of the whole machine is stable and reliable, and the wear parts have a long service life (hard rock).Optimize the structure of the rotor runner, the material accumulation is reasonable, and the life of wear-resistant parts is increased. Reduce the unbalanced force of the rotor, reduce the radial force of the main shaft, so as to improve the life of the bearing, reduce the vibration of the crusher, and the rotor operation balance effect is good.

- High performance: Lightweight rotor, high power density, high sand formation rate cavity technology is adopted to achieve output increase and energy saving.

- Low cost: Breakthrough in high wear-resistant composite material technology, wear resistant parts life extension, the use of center + waterfall automatic control, center feeding with waterfall feeding, the processing capacity can be increased by 30%, can meet different requirements such as sand making, shaping, etc., reduce the cost of use, reduce operating costs, and create value for customers.

- Intelligent: Realize the functions of automatic adjustment of overflow flow, adaptive matching of speed, and intelligent monitoring of the wear of the main hammer head, so as to realize unattended and excellent equipment attendance.

Recommended products

Related testimonials

China's first hybrid electric grab Sany SH750E helps the Yongding River Upgrading Project in the capital and installs "steel and iron bones" for the embankment

2024.12.27

Water-mediated | The first set of pure water brackets in Northeast China was launched

2024.12.10

Sany rotary drilling rig helps the construction of the 228 National Highway (Wenling Section of Taizhou City) project

2024.10.30

0 comments