Soul torture: What are the advantages of prefabricated load-bearing exterior walls?

2024.01.15

Trinity Builders

In the previous article, we introduced in detail the structural safety and waterproof performance of prefabricated cavity walls. In addition, the prefabricated cavity exterior wall can also integrate insulation to realize the integration of insulation structure and reduce the risk of insulation falling off caused by traditional post-sticker insulation. Next, we continue with "soul torture".

Prefabricated wall panel construction

Soul Torture 3: The exterior wall of the building is divided into load-bearing walls and non-load-bearing enclosure walls, is there any difference between these two types of exterior walls for prefabrication?

This question should be viewed according to different building functions, and let's talk about the housing that ordinary buyers are most concerned about. At present, most of our country's residential products are shear wall structures, and the shear wall structures themselves have excellent seismic performance. When designing shear wall structures, placing shear walls at the corners of the building can also help improve seismic performance. In addition, reducing the masonry of the exterior wall and increasing the prefabricated exterior wall not only reduces the wet work on site and improves the efficiency of on-site construction, but also reduces the joints of different materials of the exterior wall, and can also improve the waterproof performance of the exterior wall. In addition, the fully prefabricated exterior wall also creates conditions for the realization of in-the-construction operations. The so-called in-plane operation is to reduce the external scaffolding in the main construction stage and transfer all workers' construction to the building plane, which not only improves safety but also reduces construction costs. It can also reduce the risk of exterior wall cracking and improve waterproof performance. Therefore, when designing prefabricated houses, it is recommended to make the exterior walls as prefabricated as possible.

In-plane operation construction

At present, there is also a construction system for internal and external plug-ins on the market. The so-called internal and external plug-in means that the main structure is cast-in-place, and the outer protective structure is in the form of prefabricated hanging plates. The first problem of internal and external hanging is that only the non-load-bearing enclosure wall is prefabricated, which does not fundamentally solve the prefabrication problem of the main structure, and it is difficult to achieve the efficiency of fewer people on the construction site. Therefore, the cavity backpouring superimposed façade is the best choice for the current industrial façade of buildings.

For general shopping malls, office buildings and other public buildings, it is often framed or framed. This structural form ensures the flexibility of the internal space function, and there is basically no structural shear wall in the position of the exterior wall. For this case, the exterior wall is generally realized by building curtain wall or AAC strips. AAC slats are a kind of autoclaved aerated concrete slabs, which have the advantages of low price, light weight and high strength, thermal insulation and insulation, and are widely used in building exterior walls.

Soul Torture 4: Is it convenient for prefabricated houses to be redecorated in the later stage of the house?

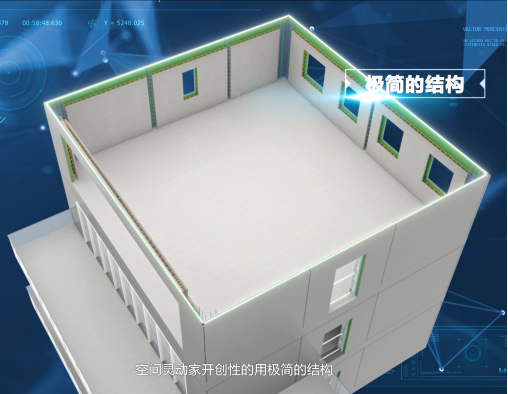

In the design stage, we can add prefabricated load-bearing exterior walls while reducing the layout of internal load-bearing walls, with flexible partition wall systems to achieve flexible and variable indoor space. Based on this,Trinity BuildersThe architectural concept of SPCH is proposed, that is, the infinite possibilities and scalability of internal functions are supported by a minimalist and reliable structural system. There are three main characteristics, namely "large space", "spirit" and "movement".

The core of the "large space" is to emphasize the simplicity of the main structure, in addition to meeting the necessary lighting and ventilation needs to have a certain concave and convex, the outline of the main structure is as simple and square as possible, the form is to completely cancel the load-bearing walls and structural columns in the house, all vertical load-bearing structures are arranged along the periphery, mainly oriented to the maximum openness and transparency, and the large indoor space has no beams and columns, which provides basic conditions for meeting the variable space needs of residents. The richest variability in the interior space with the least structural constraints.

Schematic diagram of "large space"

"Spirit" is building intelligence. The intelligent building of the future will become one of the largest intelligent terminals in the future, and the largest collector and provider of daily data and information.

"Moving" refers to bringing residents a comprehensive choice of functional layout and living mode through the "moving" partition wall system, menu-based flexible house design and complete technical factory customized parts. Non-load-bearing partition walls can be purchased and installed, disassembled or adjusted like furniture, safe, quiet, fast and environmentally friendly, without disturbing neighbors, and can greatly shorten the construction period.

0 comments