Prefabricated buildings: the dual challenges of safety and waterproofing, have we passed the test?

2024.01.17

Trinity Construction

Since 2020, the Ministry of Housing and Urban-Rural Development has issued the "Guiding Opinions on Promoting the Coordinated Development of Intelligent Construction and Construction Industrialization": it aims to promote the industrialization, digitalization and intelligent upgrading of buildings, accelerate the transformation of construction methods, and promote the high-quality development of the construction industry. In recent years, a large number of prefabricated houses have been launched, which are new types of buildings with the prefabricated production of component factories and on-site prefabricated installation as the mode to realize the energy saving, environmental protection and maximization of the value of the whole cycle of building products. The prefabricated policy has been implemented in a large area across the country, and most of the houses we will buy in the future will be prefabricated buildings. So for ordinary home buyers, what are the differences between prefabricated houses and traditional houses? Is the prefabricated house worth buying? Today, we will conduct a "soul torture" on the dual challenges of safety and waterproofing of prefabricated buildings.

Soul torture 1, is the prefabricated house safe?

The prefabricated development of many developed countries started earlier than China, and they also have more mature practical experience. For example, France has a 130-year history of prefabricated building development, and the current prefabricated assembly rate in France has reached 80%. The second is the United States, the United States also has nearly 100 years of prefabricated building development history, and as early as more than 40 years ago for industrial buildings to legislate, and the introduction of relevant industry norms, requiring not only to pay attention to quality, but also to pay attention to aesthetics, at present, the United States affordable housing mainly uses prefabricated buildings, of which one in every 16 people lives in prefabricated buildings. In 1968, Japan proposed the concept of prefabricated housing, and in 1990, it launched the "middle and high-rise housing production system" that adopts componentization, industrial production methods, high production efficiency, variable internal structure of houses, and adapts to the different needs of residents. The precast concrete structure built during this period withstood the 1998 Hanshin 7.3 magnitude earthquake.

Looking at the country, China has been vigorously developing prefabricated buildings, promoting the coordinated development of building industrialization and intelligent construction, and during the 14th Five-Year Plan period, prefabricated buildings will account for more than 30% of new buildings. With mature experience abroad and policy support at home, there is no need to worry about the safety of prefabricated housing.

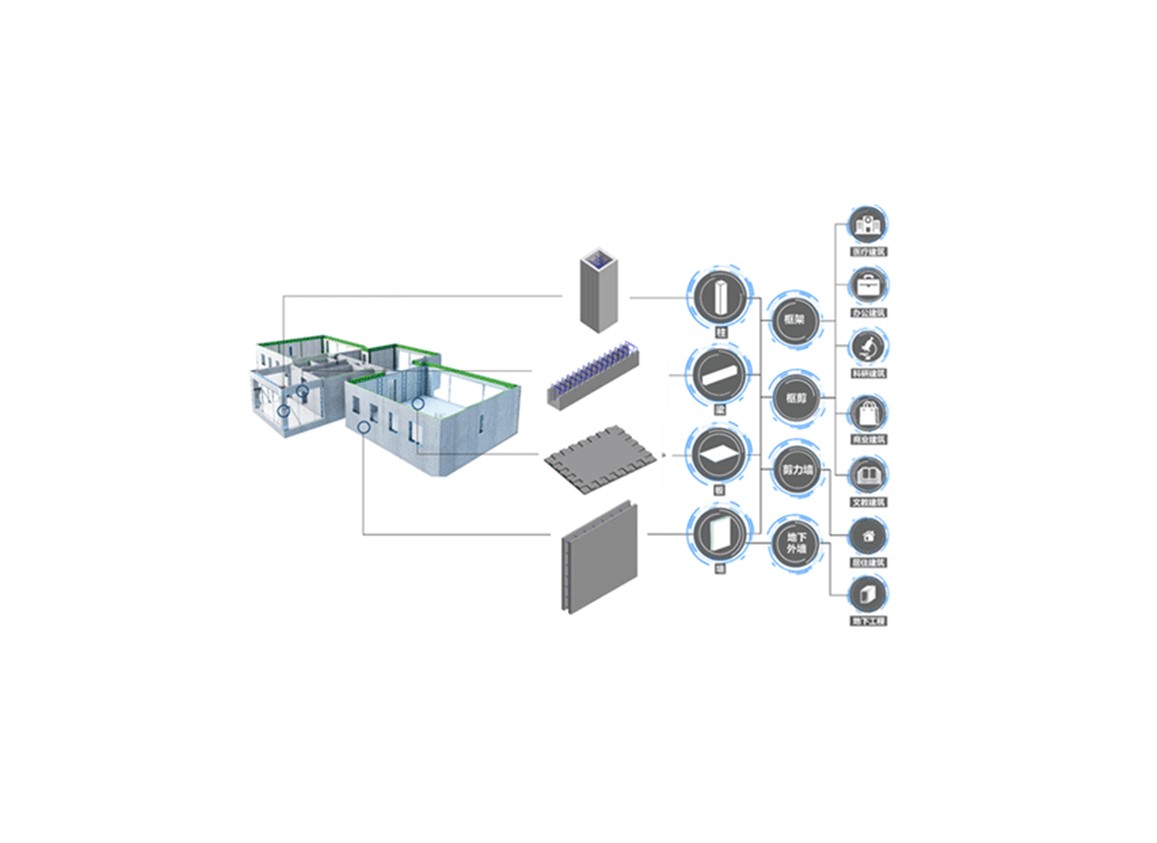

Secondly, at the level of structural safety, to:Trinity ConstructionThe SPCS structure system developed by the development is an example. In cooperation with China Building Science Research, the system has proved through a large number of stress tests that the stress and failure modes of SPCS system components are consistent with those of cast-in-place components, and have the same seismic performance as cast-in-place structures. At the same time, the technology has passed the evaluation of scientific and technological achievements of third-party organizations, and the technology has been well received by academicians and experts, and it is believed that the complete set of technologies has reached the international advanced level. At present, the projects of SPCS, the overall solution of Sany intelligent construction, have exceeded 10 million square meters across the country, and many projects have been delivered. The first phase of the Changsha Yungu project has been fully completed in November 2023, and the project has been selected as the 2023 Changsha Intelligent Construction Pilot Demonstration Project. The project uses Sany Construction's SPCS structural technology system on the ground and underground, and the above-ground part mainly applies the technology of "cavity wall column + molded node + lap post-casting", and the underground part applies "cavity prefabricated exterior wall + cavity superimposed column" to realize "full prefabrication of walls, columns, beams and slabs, and full assembly of aboveground and underground".

Therefore, ordinary home buyers can buy prefabricated buildings with confidence and do not need to worry about the safety of prefabricated buildings.

Changsha Yungu Project

Changsha Yungu Project

Soul torture 2: Will the prefabricated house leak?

As an ordinary home buyer, there must be worries. Can a prefabricated house leak? Let's start with the prefabrication of the façade.

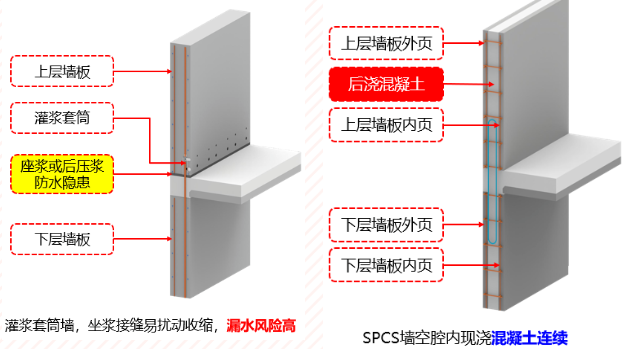

Traditional solid prefabricated exterior wall SPCS system is upgraded to superimposed exterior wall

The bottom of the traditional solid prefabricated exterior wall is not completely hard with the floor slab, but there is a 2cm joint, which is generally treated by seat grout or post-grouting treatment, which itself has a certain waterproof ability. However, considering that in the extreme circumstances that may exist, there will be waterproof hazards such as cracking in the slurry joints, so there are generally waterproof mortar and other building waterproofing practices on the outside of the structural wall to ensure that the exterior wall does not leak. At this stage, the SPCS system has once again upgraded the waterproofing of the prefabricated exterior wall, which is characterized by the wall consisting of leaf plates on both sides and a reinforcement cage in the cavity, which needs to be poured concrete twice on site. At this time, the leaf plates on both sides are not only part of the structural force, but also act as a template for the cast-in-place cavity, which is basically the same as the cast-in-place structure. The concrete in the cavity is poured continuously when the upper and lower layers are poured, and concrete of the same strength is used, so the waterproofing ability will be better, so you can not worry about the waterproofing performance of the superimposed prefabricated exterior walls.

For floor slabs, most of the current applications in ordinary residential projects are laminated floor slabs, which are composed of a prefabricated layer of 6cm at the bottom and a post-poured layer of 7cm at the top. Due to the existence of the top 7cm post-poured layer, there will be no obvious slab joints on the laminated floor slab, and its overall waterproof performance is almost the same as that of cast-in-place. In addition, the indoor environment is generally dry, so there is no need to worry about water leakage on the floor.

0 comments