Strength interprets excellent quality! Sany filling pumps continue to be delivered

2024.06.05

Recently, the warm breeze has been blowing with good news. Sany 11020 typeFilling pumpsAnd Sany 25016 filling pump were shipped to Fujian and Shandong without interruption, starting a new journey!

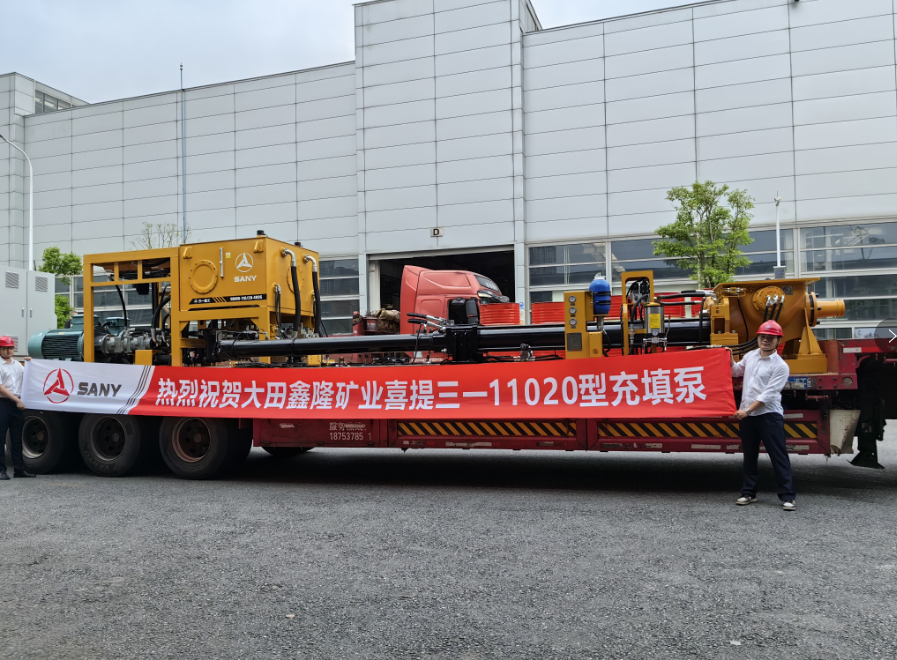

11020 filling pump: help the construction of Fujian Datian Xinlong Mining

The 11020 filling pump delivered by Fujian Datian Xinlong Mining is an EPC general contracting project of Changsha Mining and Metallurgical Research Institute under Minmetals Group, and Sany filling pump is the designated product of Xinlong Mining.

In terms of the development and utilization of mineral resources, Changsha Institute of Mining and Metallurgy has four main majors: mining, mineral processing, metallurgy and materials, and has been the main undertaking unit of national scientific and technological projects for comprehensive utilization of resources since its establishment. At present, it has reached in-depth cooperation with Sany on a number of metal mine filling projects, complementing each other's advantages, and will jointly contribute to the development of metal and non-metal mine filling fields at home and abroad.

25016 Filling Pump: Assist the construction of Pengzhuang project of Shandong Energy Group

Shandong Energy Group is a large-scale energy enterprise group established by the Shandong Provincial Party Committee and the Provincial Government in July 2020 by jointly reorganizing the former Yankuang Group and the former Shandong Energy Group. Its Pengzhuang Coal Mine Filling Mining Construction Project includes two parts: the construction of an underground paste filling station and the construction of an underground 4305 working face. Among them, the total investment of the paste filling station construction project contract is more than 7,000 yuan, covering an area of 36.7 acres, with a designed annual filling capacity of 800,000 tons.

The project has been in preparation since April 2023 and has now started in full swing. The project is of great significance for the liberation of overlying resources under mine construction, reducing rock burst disasters and extending the service life of the mine.

Sany Filling Pump: A game-breaking tool for green and efficient coal mining

Under the guidance of the "dual carbon" goal, the harmless filling of bulk solid waste coal gangue has become a "hard task" and "hard index" for the green development of coal mining enterprises. In order to better meet the needs of customers and help the industry develop better and faster, Sany Heavy Industry tailors Sany filling complete sets of equipment for coal mining enterprises, which are more professional, more efficient, more intelligent and more reliable!

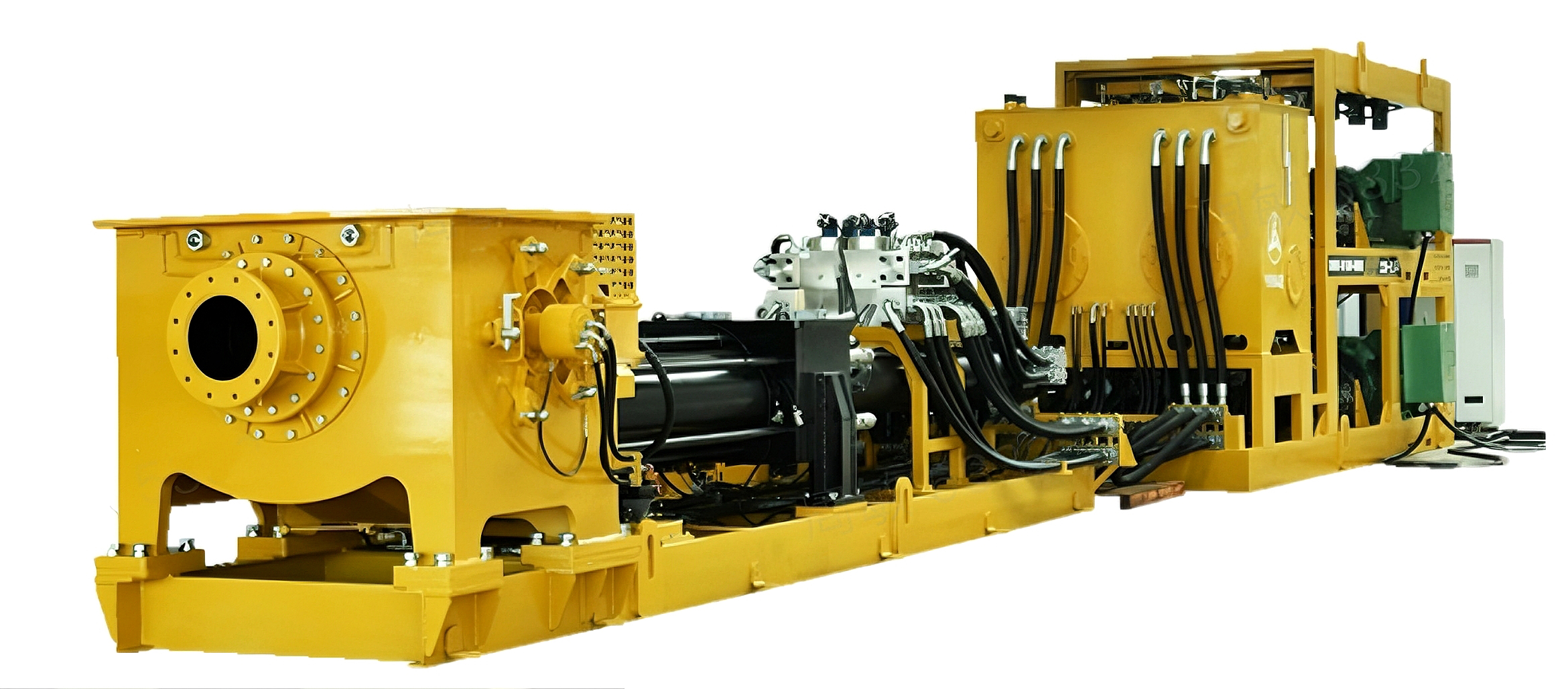

Among them, Sany filling pump integrates the pumping technology of Prometheus and Sany construction machinery for many years, creating the three core technical advantages of Sany filling pump with strong pumping capacity, high reliability, and less/no blockage.

【Strong pumping capacity, rest assured to buy】

Ultra-high pressure pumping technology: Sany is the world's largest concrete machinery manufacturing enterprise, concrete pump trucks, concrete trailer pumps on the market share list for many years, and the country has been built and under construction of more than 300 meters of high-rise buildings, 80% by Sany ultra-high pressure pumps to participate in the construction.

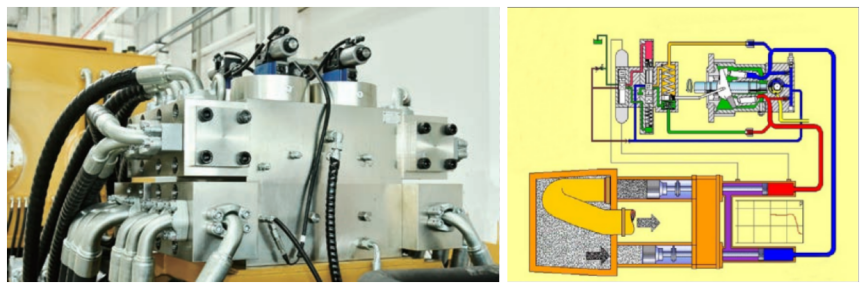

PM core technology integration: full R&D platform, R&D system interoperability, cooperative development of industrial pump products, localized production of Purmey filling pumps, and deep integration of new poppet valve constant flow technology.

Large displacement pumping technology: displacement up to 400m³/h, pumping pressure up to 20MPa, power up to 1800kw, maximum conveying distance of more than 8 km.

【Highly reliable and comfortable to use】

Integrated large-bore main valve: simple and reliable structure, large inner diameter (DN80), low pressure loss, small impact, flow rate up to 6000L/min, no pipe burst and no oil leakage;

The operation status of the digital main cylinder is fully controlled: the stroke accuracy is accurate to 1mm, the precise reversal, the soft buffer, the impact of the equipment itself is small, and the impact on the filling workshop is also minimized.

The hydraulic system adopts multi-group power merging technology: even if part of the power fails, the remaining power can still be pumped with a small displacement, which effectively avoids the power failure and causes pipe blockage and ensures high reliability.

[Less/no blockage, worry-free throughout the process]

Filling laboratory: In view of the differences of different mines, Sany can provide comprehensive experiments on a variety of filling processes: water leakage, expansion, strength, ring pipe, etc., to determine the accurate ratio of filling materials.

Distributed pressure monitoring: multiple pressure monitoring points are arranged on the road, and by monitoring pressure changes, it can accurately determine whether the pipeline is blocked and the specific location of the blocked pipe, and the data is transmitted in real time, so that the pressure detection points of the whole pipeline are related to each other to form a pipeline pressure monitoring network system.

Circulating filling pipeline technology: Sany routing technology, using circulating filling pipeline, can be continuously filled. Partial pipe blockage, the flow channel can be switched to achieve the purpose of pipeline self-dredging.

【Widely used in the market and deeply trusted】

Thanks to its excellent product performance and international leading configuration, Sany filling pump has excellent performance in practical applications. The unique pumping and conveying process improves the efficiency of paste filling and tailings utilization, which can effectively digest gangue and truly realize green mining.

I believe that in the near future, more and more high-quality Sany filling pumps will appear and put into use, making greater contributions to the sustainable development of the mining industry, let us look forward to it together!

Recommended products

Related testimonials

Pure electric drive clean, a new 18T pure electric cleaning car

2025.06.25

Electric drive strong voltage, net enjoyment of the future丨Pure electric compression garbage truck

2025.06.24

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

0 comments