Sany "Smart Brain" helps the construction of Minmetals Graphite Smart Mine

2024.06.17

Sany Heavy Machinery

Recently, Sany Heavy Machinery Zhongdig and Xiaodug Company jointly developed and successfully delivered two remote-controlled excavators to Minmetals Graphite, helping to create a new blueprint for smart mines. In the graphite mining area of Minmetals, Sany remote-controlled excavators are mainly used for the crushing of graphite blocks, the crushing of frozen soil on the cliff side, and for dealing with dangerous working conditions such as unexploded detonators.

The vigorous rise of technology and industry continues to accelerate the upgrading process of mine digitalization. With emerging technologies such as 5G and AI, Sany remote-controlled excavators have been able to show their skills in mine construction.

Remote control, unmanned mode on

Sany remote control excavator supports a variety of different operation methods such as portable handheld and cockpit remote control, and the operator does not need to sit in the cab, but can realize the remote control operation of various actions through the handheld remote control or sitting on the remote control console. At the same time, according to the operation needs, it can also adapt different attachments to effectively meet the operation requirements of customers in a variety of scenarios.

Flexible networking, remote control is extremely smooth

The remote control system based on 5G system communication adopts the most advanced h265codec technology, which has excellent adaptability to broadband and delay jitter. The remote control distance can reach 3 km, and it can be flexibly networked in different environments. It has millisecond-level ultra-low signal delay, ultra-low video delay ≤100ms, and the operation screen can be transmitted in real time and losslessly, realizing remote perception and human-computer interaction of audio and video, excavator operation attitude, etc.

One cabin is multi-purpose, and multi-aircraft linkage is achieved

Virtual training and remote control can be switched between each other to achieve the effect of multi-purpose in one cabin. The remote control cabin supports one-key switching of the control of multiple machines, and by switching the link of different remote control excavators, a single remote control cabin can realize the control of multiple remote control excavators, which further strengthens the modularity of the remote control cabin. In this project, the remote control cabin realizes the function of "one support two", which can be switched to remote control of SY335 excavator and SY135 excavator, whether it is remote control cockpit or handheld remote control, it can realize the stable control of SY335 excavator and SY135 excavator breaker.

Virtual training, simulated excavator to help get on the job

A virtual training system built on the basis of a remote control cabin. It has the real operation feel of traditional excavators, and through the safety training mode, it can speed up the process of new employees.

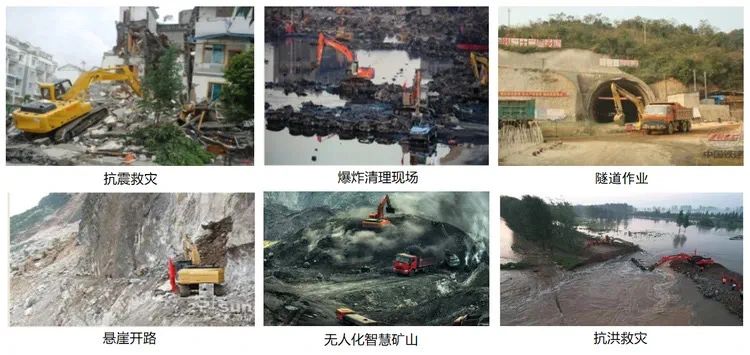

Based on the remote control operation platform, in addition to operating in smart mines, unmanned wharves and other scenarios, remote control excavators also play a vital role in government emergency rescue and unexploded bomb detection and excavation.

The right-hand man of emergency rescue and rescue

1. Auto-follow is configureddroneThe operation is flexible and reliable, and it can automatically follow the operation movement of the excavator and observe the working conditions from a bird's-eye perspective, which greatly improves the operation efficiency and safety.

2. With the "little sun" of emergency rescue, the lighting area can reach 10,000 square meters, and the continuous illumination can be exceeded for more than 12 hours, which enhances the excavator's ability to operate at night and meet the needs of high-intensity operations.

3. Provide a highly simulated construction environment and carry out multi-machine collaborative training. With the real operating handle of the excavator, the game mode is developed to educate and entertain, reduce training costs, and avoid safety accidents.

Sany Heavy Machinery will continue to promote digital and intelligent transformation, relying on 5G + unmanned driving, extending and expanding in multiple intelligent directions such as remote control of equipment and intelligent safety management and control, constantly exploring and defining industry products, and providing customized intelligent remote control solutions for more working conditions.

0 comments