Sany Construction's SPCS technology system helped Beijing Minute Temple Resettlement Housing Project to be successfully capped

2024.08.23

Trinity Construction

Recently, the resettlement housing project of Beijing Minute Temple ushered in the capping of all buildings, marking another major achievement in the application and practice of Sany Construction's SPCS technology system in the field of building industrialization. This project fully applies the SPCS technology system, and has achieved the overall advantages of "excellent structural safety cost, green wisdom and fast saving", and avoids the pain points of traditional prefabricated building components, such as heavy weight, difficult installation and poor quality. Next, we will introduce the application of SPCS technology system in this project in detail.

1. Project Overview

The residential and supporting projects of Block C of the Minute Temple Resettlement Housing are located in Minute Temple Village, Nanyuan Township, Fengtai District, Beijing, with a total construction area of 124,941.17 square meters, with a total construction area of 124,941.17 square meters. The project is composed of 1# resettlement building, 2# resettlement building, 3# resettlement building, 4# resettlement building, 5# resettlement building, 6# pension supporting building, underground garage, etc., of which 1#~5# building adopts SPCS cavity system. The bird's-eye view renderings of the project are detailed in Figure 1, and the construction renderings of the project are detailed in Figure 2.

Figure 1: Aerial view of the project

Fig.2 Construction drawings of the project

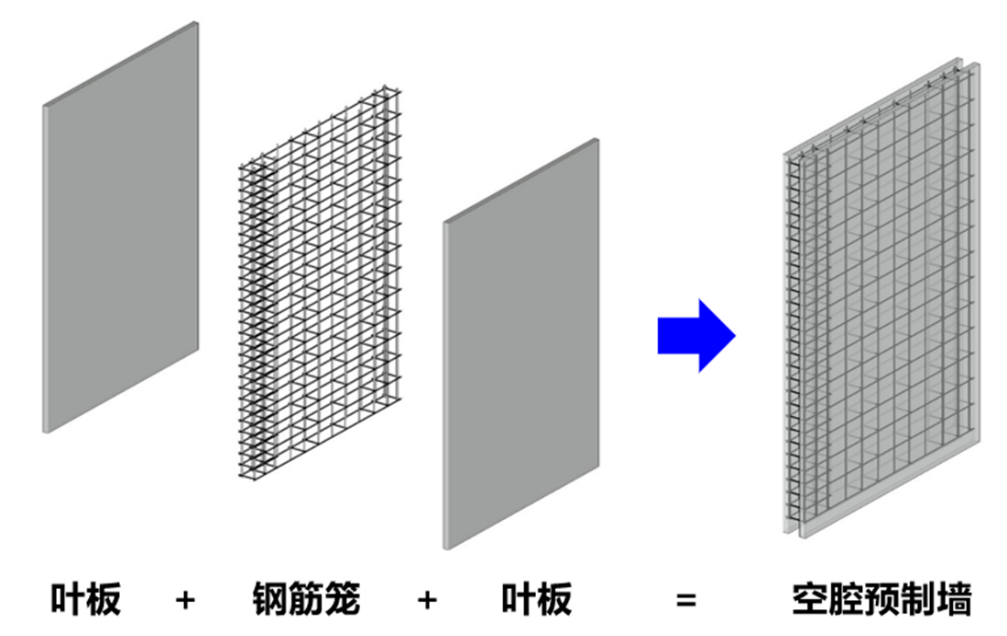

2. Introduction to SPCS cavity wall technology

The structural form of this project is a shear wall structure, and the prefabricated components are all SPCS cavity wall components. The basic form of SPCS cavity wall components is "no reinforcement on all sides, full prefabrication on both sides, large cavity in the middle, and strong connection of steel bars".

(1) Fully prefabricated on both sides: The wall reinforcement cage is produced in the factory to form cavity components with concrete shells on both sides through the flipping process, and the reinforcement cages are anchored in the shell plates on both sides. The prefabricated enclosure acts both as a site formwork and as part of the stressed structure. The practice of full prefabrication on both sides significantly reduces the workload of tying steel bars, supporting formwork and dismantling formwork on site.

(2) Large cavity in the middle: Concrete is poured in the cavity of the component on site to form a complete stressed structure.

(3) No reinforcement on four sides: the characteristics of the two pages of the cavity wall without reinforcement on all four sides make the side mold do not need to reserve the rib opening, so that the reuse rate of the side plugging mold is high, and the amortization cost of the mold is also greatly reduced.

(4) Strong connection of steel bars: The reinforcement cage of Sany SPCS cavity wall is integrally formed, so that the prefabricated slabs on both sides will not be dislocated due to external force in the transportation link and construction link, and the structural performance is better.

The composition of the SPCS cavity wall is shown in Figure 3.

Fig.3. Composition of SPCS cavity wall

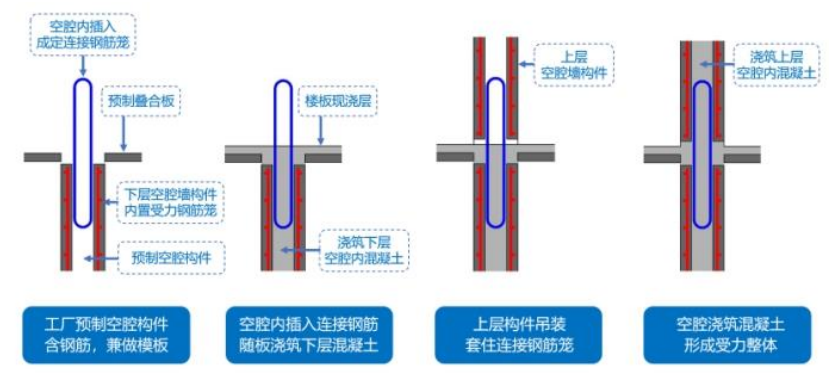

In terms of vertical connection technology, the connecting steel bar is first inserted into the cavity wall, the floor slab is hoisted, and the concrete in the cavity is poured, and the concrete strength reaches the specification requirements. Then the lower part of the upper cavity wall is sleeved to connect the reinforcement cage, and the concrete in the upper cavity is poured to complete the overall force of the upper and lower layers (see Fig. 4 for details).

Fig.4. Vertical connection mode of cavity wall

Third, the application effect

3.1 Design Advantages

In this project, PKPM+SPCS forward deepening design software is used to carry out the detailed design of SPCS components. The software can realize functions such as intelligent splitting, one-click drawing, and driving intelligent equipment, which significantly improves the efficiency of component deepening design.

3.2 Production advantages

The SPCS cavity walls used in this project are all processed and produced in the Sany Construction PC South Exit Lighthouse Factory. Sany Construction Engineering independently developedSPCI Industrial SoftwareIt can automatically analyze the PKPM+SPCS design model data, drive intelligent marking machine, formwork machine, flipping machine, placing machine and other equipment (see Figure 5 for details) to carry out intelligent production, ensure that the appearance size of the component and the quality of pouring vibration are greatly improved compared with manual operation, and the appearance and quality of the surface are more guaranteed. The quality of the component is good, which is more convenient for on-site installation and operation.

Figure 5 Intelligent PC production line equipment

3.3 Construction advantages

(1) The construction speed of SPCS wall system is faster

Due to the large cavity inside the SPCS cavity wall, the cavity has high fault tolerance, easy centering and fast hoisting, and it takes 7-10 minutes to install a wall. The on-site construction photos of SPCS components are detailed in Figure 6.

In addition, due to the large cavity inside the SPCS cavity wall, the components are light, and the large-size components can be made, which can realize the advantages of one wall and one board, less joints, less binding and less formwork, etc., and ensure that the project can achieve the construction speed of one floor in five days in the construction period. This is a very important point for Party A, which provides a solid guarantee for the smooth progress of the project.

(a) SPCS component hoisting

(b) SPCS component installation

Fig.6. On-site construction photos of SPCS components

(2) The SPCS technical system can be used for winter construction

With the traditional sleeve grouting solid wall system, winter construction will not be possible in many areas of the north. Because in accordance with the provisions of Article 6.3.9 of the "Technical Regulations for the Application of Steel Sleeve Grouting Connection" JGJ355-2015, the ambient temperature of the sleeve grouting connection technology is not suitable for construction if it is lower than 5 °C, and it should not be constructed if it is lower than 0 °C.

The construction of SPCS system is less affected by winter, because the system does not use grouting material, the working environment is consistent with the cast-in-place structure, and the conventional winter construction measures can be used to carry out the construction operation normally in winter or during the low temperature. This will bring greater benefits to the improvement of Party A's construction progress.

(3) The degree of industrialization is high, and the on-site construction personnel are greatly reduced.

The prefabricated part of the SPCS cavity wall element is both involved in the force and serves as the formwork. After using this system, the workload of steel bars, formwork, scaffolding and other work on the project site can be greatly reduced, and less manpower construction can be realized. At present, compared with the traditional cast-in-place construction method, the project saves at least 40% of labor.

(4) The quality of the project has been significantly improved

Because the surface of the SPCS cavity wall is produced by a double-sided film platform, the apparent quality of the components produced is better, and the internal cavity of the SPCS cavity wall is easy to adjust after installation and easier to install accurately, so the overall quality molding after pouring is better.

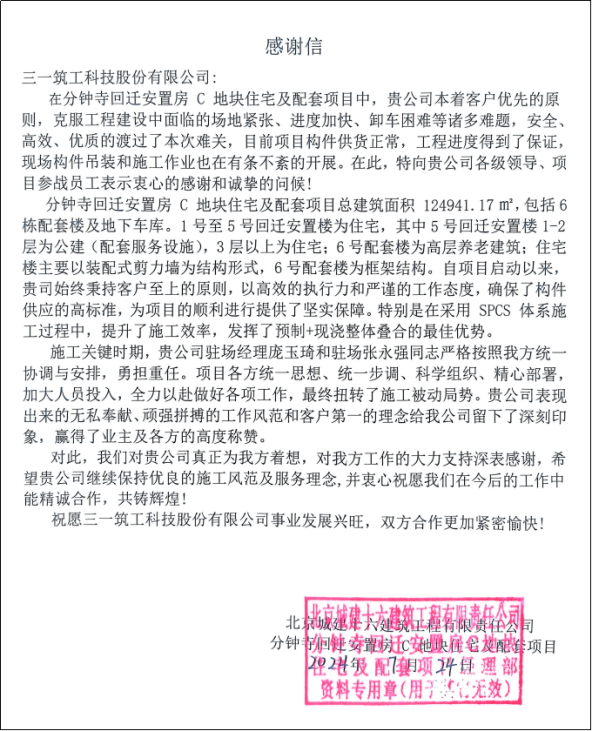

3. SPCS technology has been recognized by the owner

Up to now, SPCS has won wide recognition and high praise from the project owner and all parties involved in the construction, and the general contractor hereby sends a letter of thanks to us (see Figure 7). This not only demonstrates our excellent service attitude from the side, but also fully reflects the strong advantages of SPCS technology system. At the same time, the project leader also hopes to work with our company to promote the application of SPCS technology system and create greater value for the development of the prefabricated building industry.

Figure 7: Project thank you letter

Facing the future, Sany Construction Engineering will continue to adhere to the project engineering standard of "making a project and building a monument", continue to forge ahead, pioneer and innovate, iteratively upgrade the SPCS technology system, give full play to the greater advantages of "excellent structural safety cost, green wisdom and fast saving", and contribute to the high-quality development of China's construction industry with better Sany solutions, more Sany wisdom and stronger Sany strength.

PCM Zhuxiang Cloud Component Management System

SPCI Industrial SoftwareRecommended products

SPCI

PCM Zhuxiang Cloud Component Management SystemNext article:Sany SIME tool fixture was successfully applied to the Beijing Nankou dormitory project

Related testimonials

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Three records! The Beijing-Harbin Expressway Sany unmanned paving machine group has been under continuous construction for more than 480 hours

2025.06.20

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

0 comments