Sany Construction SPCS vertical cavity wall was successfully delivered in Hainan Vanke Sanya Bay Project

2024.09.05

Trinity Construction

Recently, the main structure of the last building of the Sanya Bay project in Sanya, Hainan Province has been successfully completed, which is inseparable from the strong organization of the construction unit Vanke Real Estate, and the long-term efforts of the construction units China Construction Second Bureau and China Construction Third Bureau. This is also the caseTrinity ConstructionAnother major milestone in Hainan.

Fig.1. Concrete pouring on the roof

1. Project introduction

Located in Tianya District, Sanya City, Hainan Province, Vanke Langshi Sanya Bay Project has a total construction area of 184,000 square meters, a prefabricated construction area of 135,000 square meters, and a total of 16 17-storey high-rise residential buildings. On-site prefabricated applications mainly include Sany Construction SPCS double-sided superimposed shear walls, laminated panels, prefabricated stairs, ALC slats, etc. The owner of the project is Vanke Real Estate, and the construction party is China Construction Second Bureau and China Construction Third Bureau. The bird's-eye view of the project is detailed in Figure 2

Figure 2 Aerial view of the project

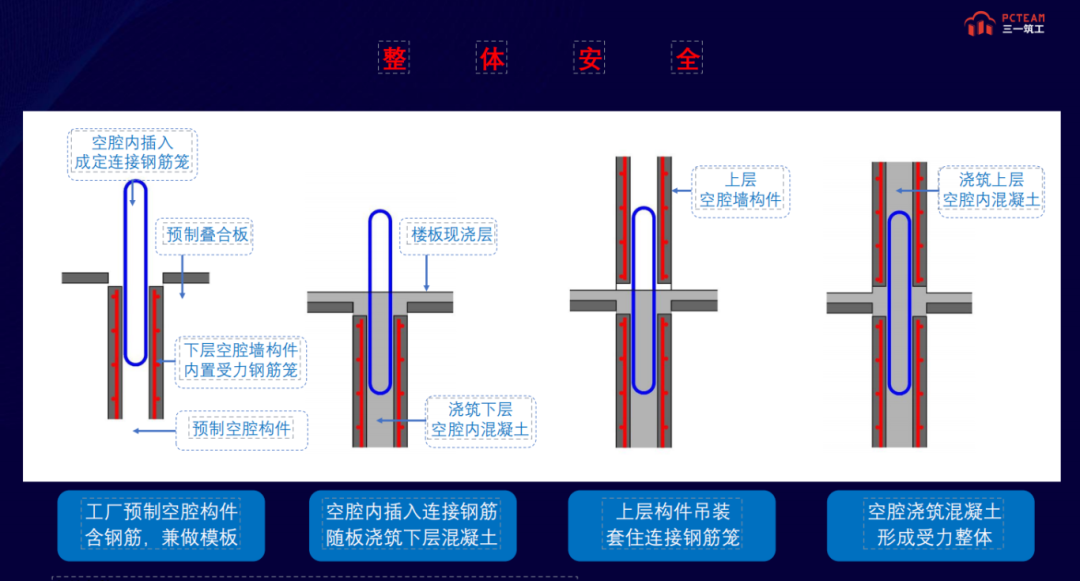

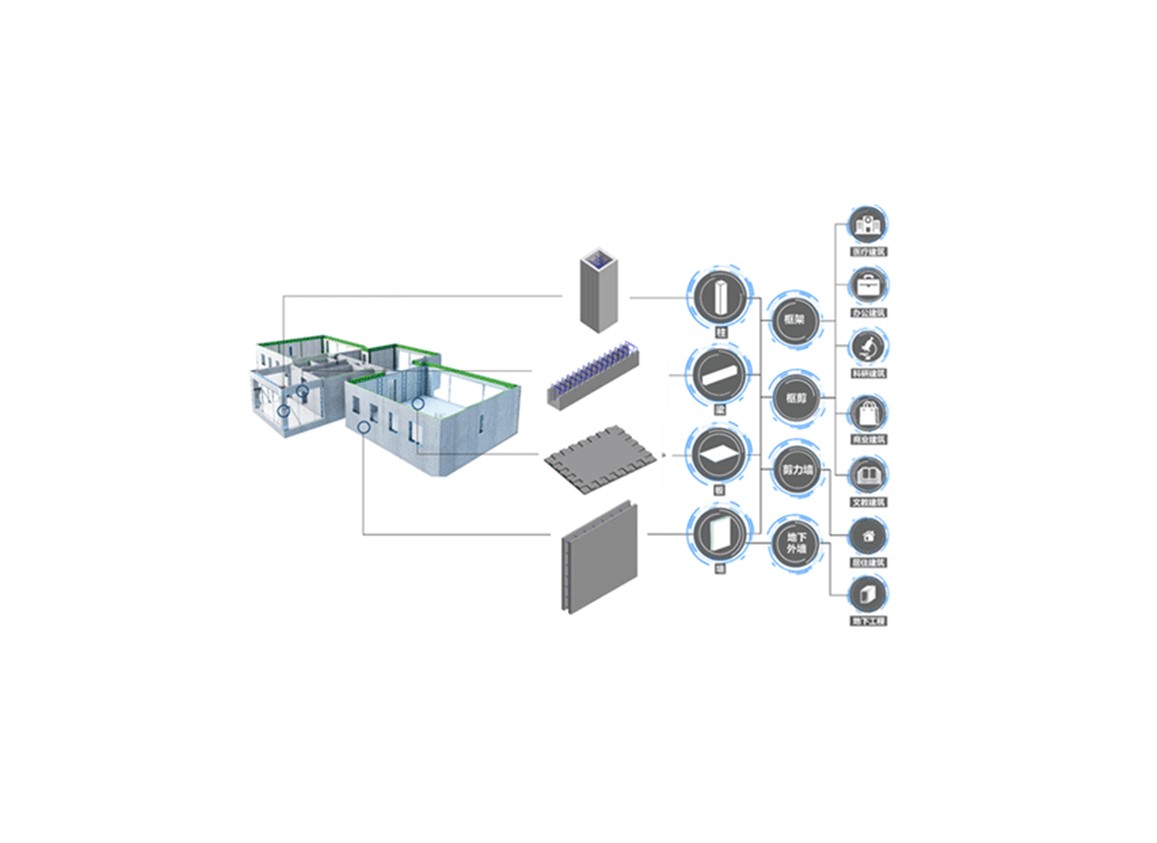

2. Technical characteristics of SPCS

The project applies Sany Construction SPCS cavity wall technology, and the example of cavity wall connection nodes is shown in Figure 3. The technical components are easy to install, controllable in quality and safe in structure, and have been widely used in Hainan, Shanghai, Beijing, Changsha and other parts of the country, with an application area of nearly 25 million square meters.

Figure 3 An example of a cavity wall connection node

3. Application effect of SPCS technology

(1) Fast production and construction speed: The 16 buildings of Vanke Langshi Sanya Bay Project are constructed synchronously, and components are supplied synchronously. The hoisting time of a single component of the cavity wall on site can be completed in only 5-8 minutes, and the average construction period of the main structure is 4 days/layer. The daily supply demand of the project site is 3-6 floors, and the main supplier is Hainan Naibowan New Material Group Co., Ltd., a cooperative factory of Sany Construction Alliance, and the daily production capacity of vertical wall panels in the factory reaches more than 100 cubic meters. At the same time, in order to ensure the timeliness of on-site supply, Sany Construction mobilized Hainan resources and adopted the form of joint supply guarantee by one company and multiple units to ensure timely supply requirements on time and in accordance with quality and quantity.

(2) Good construction quality: The vertical wall of the project adopts the combination of precast concrete cavity wall + cast-in-place aluminum mold, which has high flatness and good appearance, and can be directly plastered (see Figure 4 and Figure 5 for details).

Fig.4 The original structural surface of the prefabricated wall → Fig.5 The precast wall is directly scraped putty without plastering

In addition, in view of the problem of the combination of new and old concrete, the general contractor of the project organized the physical core-pulling test of the wall (see Figure 6 and Figure 7 for details), and the test results showed that the core samples were completely and tightly fitted, and there were no cracks. From the actual project, the reliability of Sany Construction's SPCS system theory, structural safety and controllable quality are fully demonstrated, and it has also been unanimously recognized by the owner and the general contractor.

Fig.6 Coring opening Fig.7 Concrete core sample

With the rapid popularization of Sany Construction's SPCS prefabricated cavity wall column system in Hainan, we have successfully established cooperative relations with more than 40 leading domestic real estate companies, including Vanke, Poly, China Merchants, Haikong, Datang, Jixiang, CCCC, Country Garden, etc., and jointly promoted the birth of many benchmark projects.

We recognize that the development of prefabricated buildings is a gradual and continuous optimization process. Sany Construction Engineering continues to pursue technological innovation in this field and is committed to improving the overall solution of prefabricated buildings. Through our extensive engineering practice, we have not only enhanced the value of the project, but also won wide recognition from all parties involved in the project, industry experts and government agencies.

Looking forward to the future, we firmly believe that with the joint efforts of the Sany construction team and industry partners, Sany prefabricated building solutions will inject more vitality into the high-quality development of the construction industry in China and even the world.

SPCS structural system

Structural standardsRecommended products

Next article:Miluo PC Super Factory - Intelligent Production

Related testimonials

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Three records! The Beijing-Harbin Expressway Sany unmanned paving machine group has been under continuous construction for more than 480 hours

2025.06.20

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

0 comments