Safety first | Sany Heavy Equipment Intelligent Shearer helps efficient coal mining

2024.09.11

After many intelligent function upgrades, Sany Heavy Equipment's intelligent shearer has reached the leading level in the industry, and can support intelligent mining of thin, medium and thick coal seams.With effective control strategies, coal mining efficiency and safety can be significantly improved.

Memory truncation technique

Full process:Capable of handling up to 60 process segments, supporting complex mine routes.

High Accuracy:High-precision travel encoders enable position accuracy<50mm,双冗余倾角与位移传感器确保采高数据准确可靠。

Flexible configuration:It supports online modification, manual intervention, and manual interruption, which increases the flexibility of the system and the ability to cope with different working conditions.

Offline programming

Efficiency Improvement:The setting of the memory cutting process section is carried out by the host computer, which can be set up in only 10 minutes, and the efficiency is increased by 80%.

Visualization:The curve is automatically generated in the process section, which is convenient for the visual management of the cutting process.

Flexible control

Protective Equipment:Through the preset parameters such as constant power traction, constant power cutting, and over-temperature degrading, the equipment is protected from operating within a reasonable working range and prevented from overload and damage.

Multi-machine linkage

Coordination Operations:according toScraper conveyorThe load, gas concentration, and bracket status are dynamically adjusted to ensure the efficient and coordinated work of the equipment.

Remote monitoring technology

Safe & Convenient:It realizes dual-channel redundant communication and low-latency data transmission, supports remote parameter configuration and operation, and greatly improves the safety and convenience of the working face.

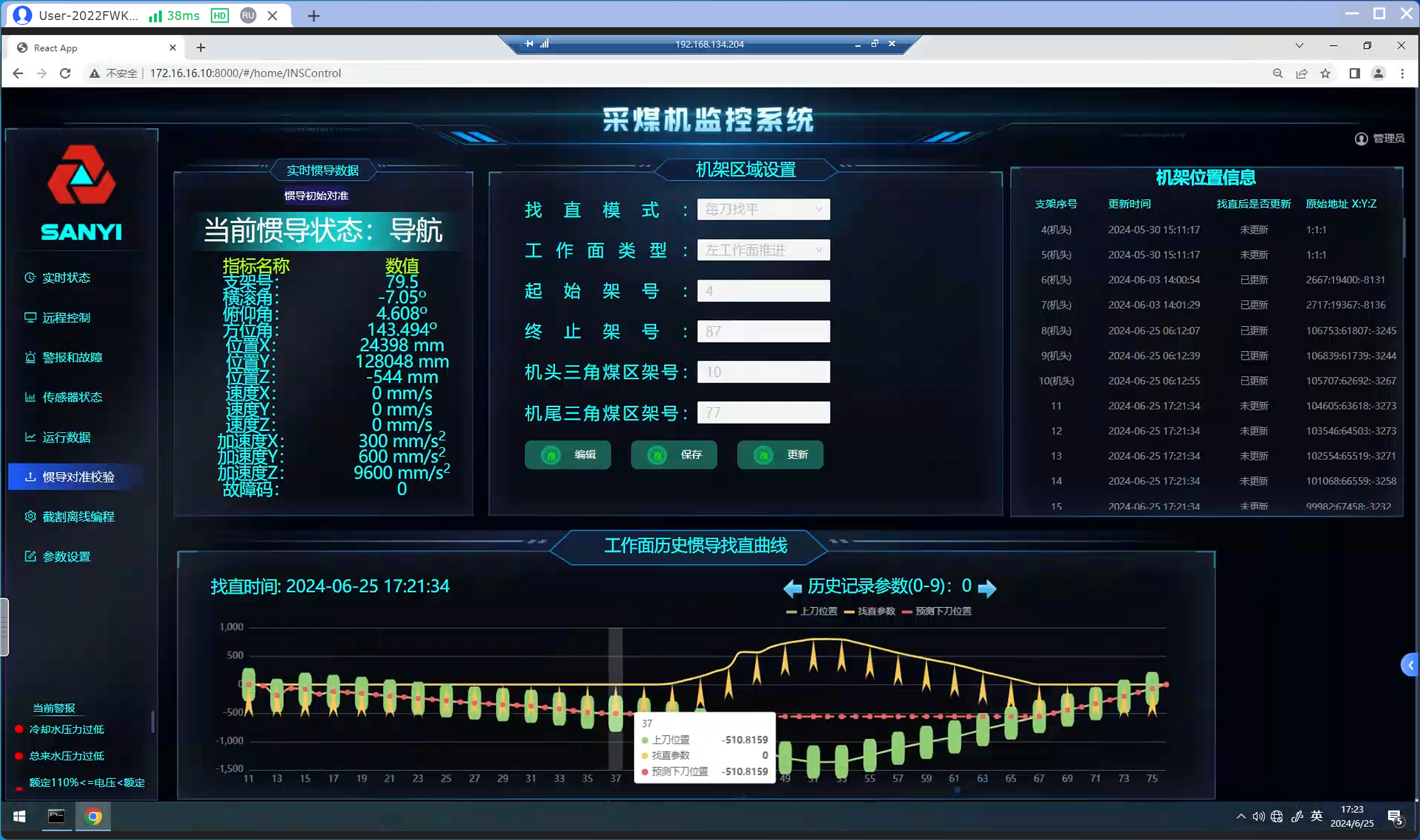

Inertial navigation technology

High-precision navigation:The use of high-precision inertial navigation accurately depicts the three-dimensional movement of the shearer, ensures the "three flats" of the working face, and effectively improves the flatness and straightness of the working face.

Heading accuracy≤0.1°;Attitude accuracy≤0.015°;

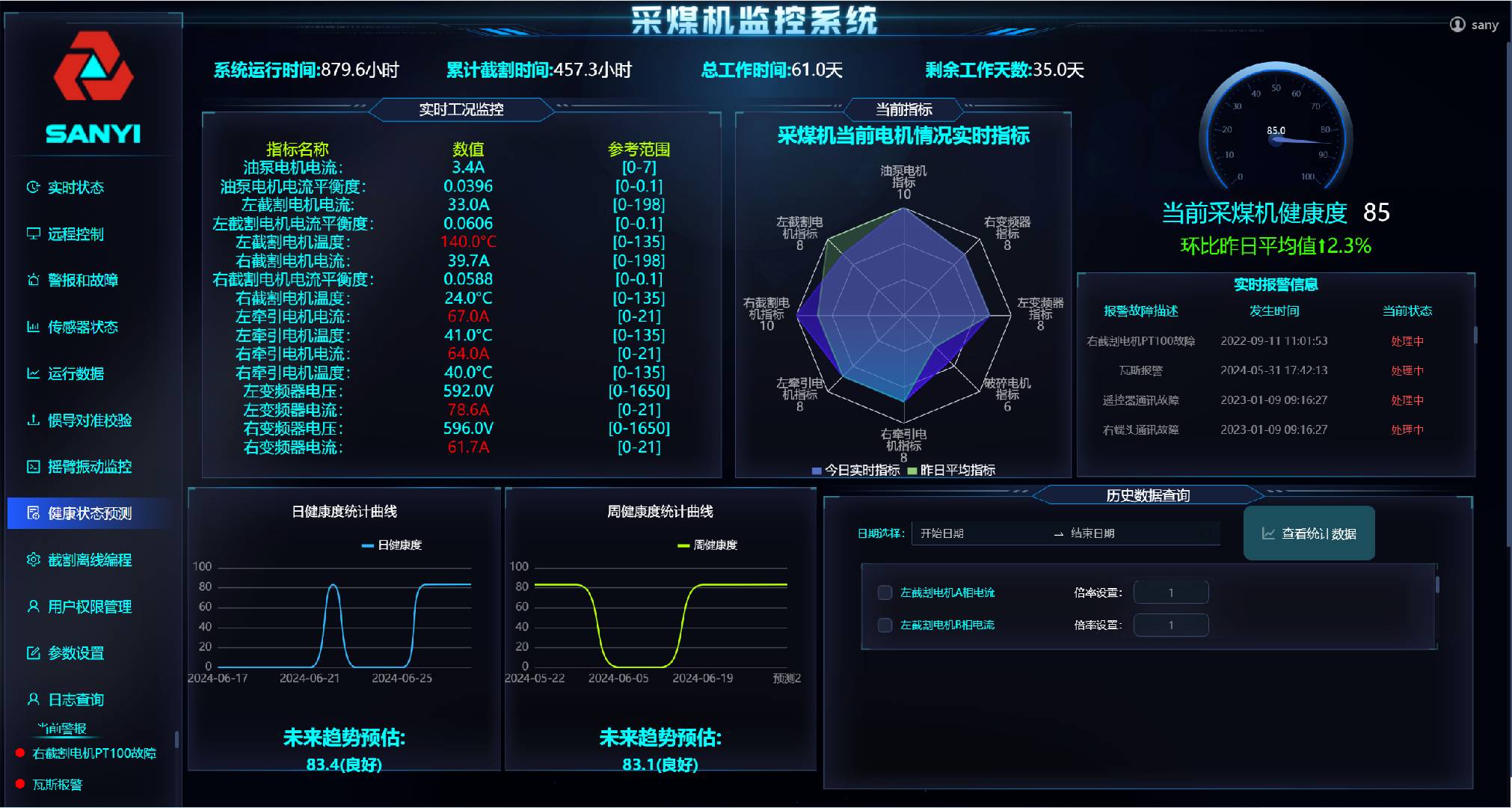

Condition recognition and prediction technology

Preventive Maintenance:Through the collection of various parameters and the comparison of fault models, the status perception, fault diagnosis and life prediction of the rocker arm and walking part are realized, and the predictability of equipment service life and maintenance is improved.

Migrating data to the cloud

Real-time monitoring:Relying on the C-end interconnection platform, it realizes the cloud display of equipment data and the monitoring of key indicators, and supports mobile devices to monitor the operation status of equipment in real time.

Remote Diagnostics:Provide remote expert diagnosis and technical support to ensure timely and accurate troubleshooting and technical guidance.

The intelligent control technology of Sany heavy shearer not only improves the automation degree and work efficiency of the shearer, but also greatly improves the safety performance of the equipment and the production management level of the working face. At present, it has helped many mines such as Gansu Huating Yanbei Mine, Anhui Huaibei Shuoli Mine, Heilongjiang Jixi Dongshan Mine, Shanxi Yangpo Spring Mine and other mines to successfully pass the provincial and national intelligent mine acceptance, and have been widely recognized and praised by customers.

0 comments