The world's first "lighthouse factory" in the wind power industry has been set by Sany!

2024.10.08

Sany Group

October 8,The world's first lighthouse factory certification in the wind power industry was established in Sany Renewable Energy Blade Factory in Shaoshan, ChinaIt has achieved a breakthrough in the lighthouse factory of the wind power industry from 0 to 1, and since then, the "intelligent manufacturing" of wind power blades in China has officially entered a new era.

Known as the "World's Most Advanced Factory", the Lighthouse Factory was selected by the World Economic Forum (WEF) in collaboration with McKinsey & Company as a demonstrator of "Digital Manufacturing" and "Globalization 4.0".It represents the highest level of intelligent manufacturing and digitalization in the global manufacturing industry today。

Looking back at the development process of wind power in China, several generations of wind power people have gone through trials and hardships, with awe of the power of nature, running out of China's wind power acceleration, bravely entering the "no man's land" of large megawatt technology and the "deep water area" of digital transformation, and leading the wave of global wind power reform with the determination of "not breaking and not standing".

As the core component of the wind turbine (referred to as the wind turbine), the blade directly affects the power generation performance and the reliability of the whole life cycle of the wind turbine, and the blade cost accounts for 20%-30% of the total cost of the unit. There is a consensus in the industry that "those who get the leaves win the world". However, the digitalization and intelligent upgrading of wind turbine blade manufacturing technology has always been an insurmountable problem for the industry, and wind turbine accidents caused by blades have also emerged in an endless stream.

Especially under the current trend of large-scale wind turbines, the length of blades has rapidly exceeded 100 meters, and the ensuing changes in material selection and production process series have pushed the difficulty of the transformation from "manufacturing" to "intelligent manufacturing" of blades to a new height.

Flowers cannot bloom in poor soil, and high-quality leaves cannot be born in backward production processes and manufacturing lines.

As a pioneer in China's intelligent manufacturing and digital transformation of wind power, Sany Renewable Energy has built the industry's first super blade factory in Shaoshan, Hunan Province based on its successful practice in the field of intelligent manufacturing of wind power hosts, subversive innovation of the traditional wind power blade production model, and ensuring the safety and reliability of the whole life cycle of blades from the source.

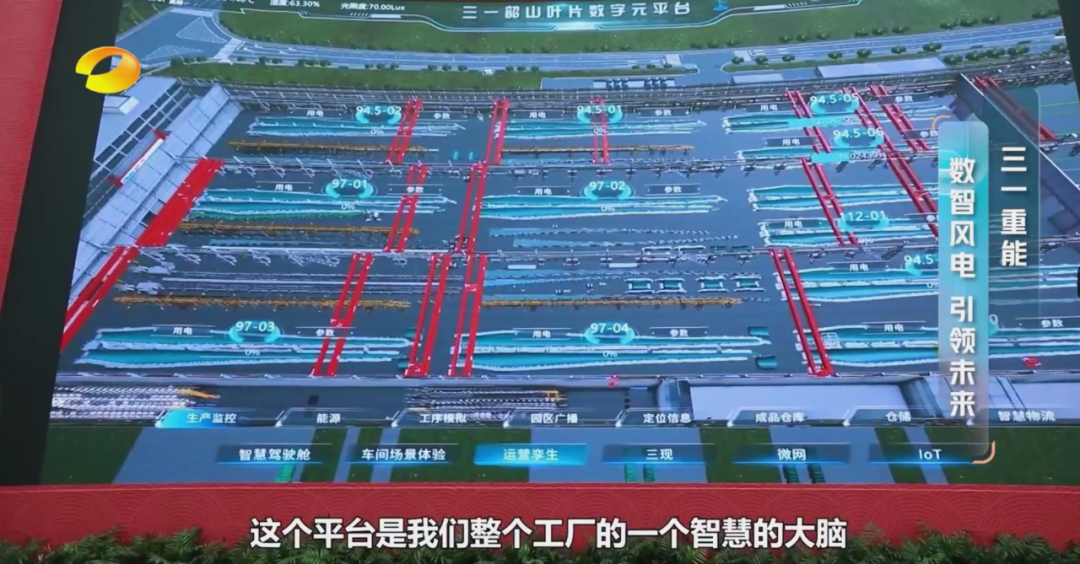

◀ Super digital ▶

Using the industry's first digital element platform to build the smart brain of the factory, an iPad can monitor all the operation and production data of the factory in real time, from the temperature and humidity of the production unit, to the process parameters and technical indicators such as bolt torque control, blade grinding and smoothing coefficient, each key indicator that affects product quality will be presented on the platform, which is equivalent to creating a "one-to-one" online digital factory outside the physical factory, so as to realize 360-degree online monitoring and lean management of the whole production process.

◀ Hyper-automated ▶

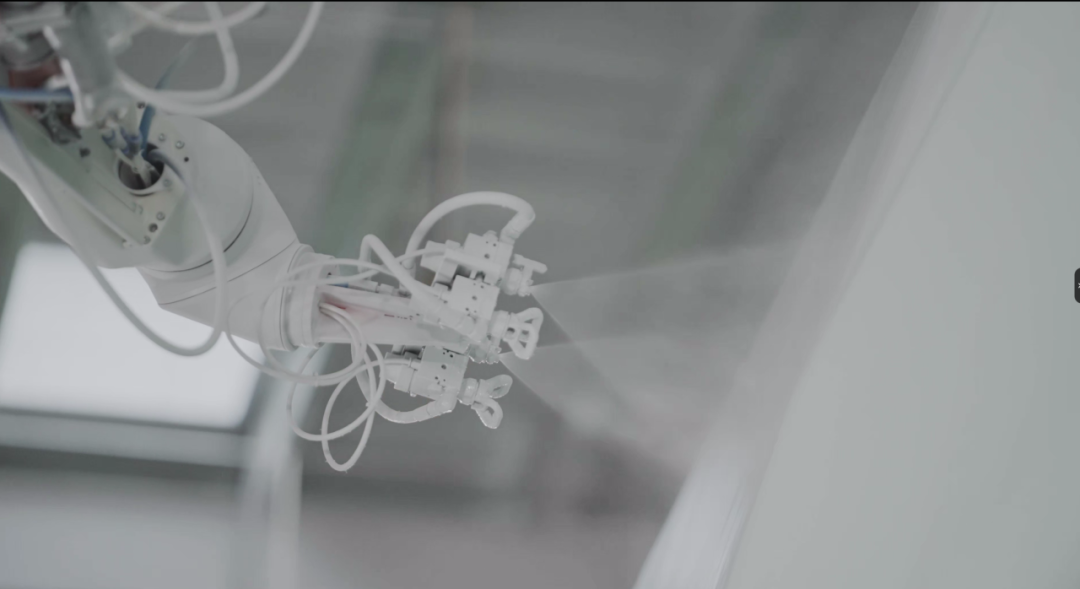

Ensuring product quality from the source is the original intention of Sany Renewable Energy to spare no effort to implement intelligent wind power manufacturing. In the past, blade production was a labor-intensive industry, and people were the most important factor of production and the biggest variable. In the production process, a large number of manual processes such as laying, pouring, grinding, and painting are required, which not only has low production efficiency, but also is difficult to ensure quality consistency.

Sany Renewable Energy's Shaoshan Blade Lighthouse Factory uses robots and laser-guided technology to realize the unmanned processes such as automatic grinding of blade surface, automatic painting of large areas, and automatic delivery of materials on demand, which reduces the labor intensity of employees while improving production efficiency and quality control to an unprecedented height.

Taking blade perfusion as an example, the Shaoshan Blade Factory has adopted the industry's first set of large-scale centralized perfusion technology to achieve a high degree of automation in the whole process of resin material intake, storage and use, making blade perfusion as convenient and accurate as a car going to a gas station to refuel, and the perfusion efficiency is increased by 25%.

As the world's first "lighthouse factory" in the wind power industry, Sany Renewable Energy's Shaoshan plant not only represents China's wind power equipment manufacturing industry among the world's first-class level, but also a successful practice of the transformation from "Made in China" to "Made in China".

Looking back on the past, the red hot land of Shaoshan not only gave birth to a great revolutionary spirit, but also witnessed the majestic power of "Made in China" in the wave of wind power in the new era. Today, Sany Renewable Energy's Shaoshan Blade Factory stands proudly at the forefront of intelligent manufacturing like a lighthouse, becoming the focus of attention inside and outside the industry, and leading the world wind power "intelligent manufacturing".

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationNext article: Warmly celebrate the 75th anniversary of the founding of the People's Republic of China

0 comments