The Global Benchmark for Smart Manufacturing: Innovative Highlights for Digital Applications

2024.12.15

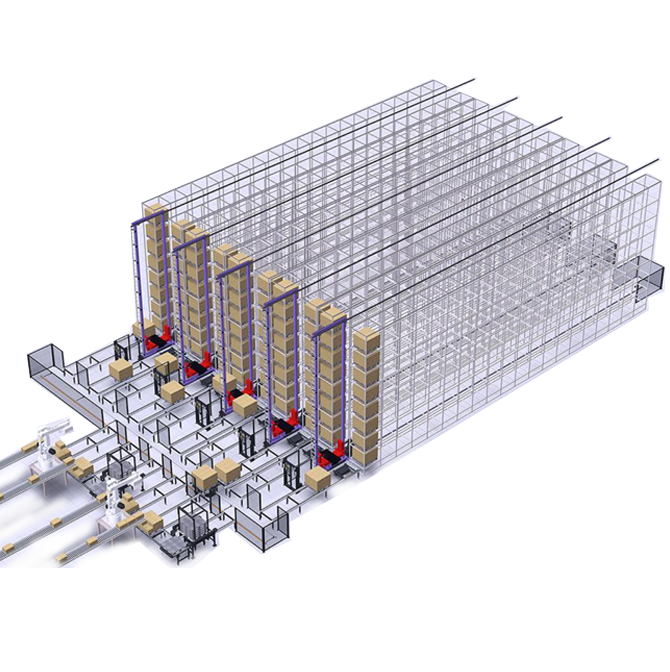

Intelligent manufacturing production base of Zhilian heavy trucks

Sany Zhilian Heavy Truck Industrial Park covers an area of 200,000 square meters, of which the heavy truck joint plant covers an area of 170,000 square meters, and the informatization efficiency is 10 times higher than that of traditional factories. The factory covers four major production processes: stamping, welding, painting and final assembly, and has 3 superStereoscopic library, 463 unmanned guided vehicles, 222 robots, is a digital manufacturing + industry 4.0 plant built by Sany Group's heavy store.

Stamping: the whole process of automated production

7,000 tons of automatic synchronous continuous stamping production line, parameterized settings and drive production

Robot automation destacking sheets, cleaning and oiling, parts handling

The workshop can produce up to 2.5 million strokes per year at full load

Welding: 100% automatic welding rate

Material storage and distribution adopt AGV unmanned intelligent distribution

EMS and APC are used for inter-line transportation of sub-assemblies, and robot picking and unloading parts are cooperated

183 robots for automatic welding

Coating: Basically realize unmanned spraying

Automatic spraying, online monitoring of the quality of the manufacturing process

Online monitoring of VOC exhaust emissions

Electricity + gas + water energy monitoring system

Vehicle tracking visualization

Final assembly: three-dimensional integrated logistics system

For the first time, a large-scale three-dimensional library was used to open up the three-dimensional space of air, ground and underground

Flexible production line: windshield automatic manipulator reclaiming + installation, automatic installation of seats

All materials are distributed by AGV+SPS

UWB personnel positioning management system, real-time positioning, trajectory analysis

The innovation of the "intelligent" manufacturing advantage of Sany Zhilian Heavy Truck Industrial Park is reflected in the fact that it is the leading automated production line in China to realize the single machine of heavy truck AGV. With AGV conveying, when upgrading products or optimizing the process, only the path or quantity of AGVs need to be adjusted, and the production line adjustment is more flexible; The innovative use of heavy-duty differential drive suspension technology realizes the forward, backward and traverse movement of the AGV, and can move the car body out in time when the production line fails, so as to ensure the timeliness of the production of the whole line.

Recommended products

Next article:Sany Electric Truck Leads Three Winters and Runs 500,000 Kilometers Electric Heavy Truck Born!

Related testimonials

Green Future, Low-carbon Sailing丨Jiangsu's largest Sany electric heavy truck was delivered to Yongzhuo Logistics

2025.05.21

It's hot! Sany heavy truck was unveiled at the Changsha International Construction Machinery Exhibition

2025.05.18

Based in Sanxiang quality to win the world, Sany Heavy Truck invites you to participate in the Changsha International Construction Machinery Exhibition

2025.05.12

0 comments