The Guangdong Highway Society went to Anhui Jingqing Expressway to inspect the Sany UAV group activity

2025.10.15

On October 12, 2025, the Guangdong Highway Society went to Anhui Jingqing Expressway to inspect SanyidroneThe group activities were successfully held. This event was highly valued by the Guangdong Highway Society, and more than ten local leading enterprises such as Guangdong Transportation Group Co., Ltd. and Guangdong Expressway Co., Ltd. formed an observation group to go to the construction site in Anhui to inspect the cutting-edge application and practical results of intelligent unmanned construction technology in highway pavement engineering for the first time.

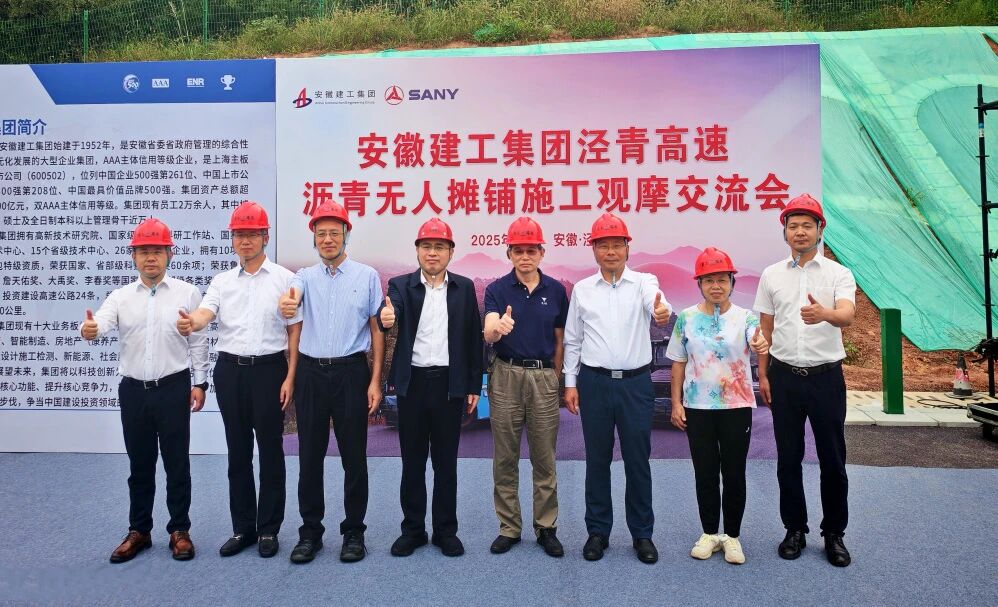

More than 40 guests participated, including Hong Xiancheng, chairman of Guangdong Highway Society, Li Weimin, chief engineer of Guangdong Transportation Group, Qian Shenchun, deputy secretary of the party committee and general manager of Anhui Construction Engineering Group Co., Ltd., Jiang Qingbin, vice president of Sany Group and chairman of the pump road division, and Sun Wei, general manager of the road machinery marketing company.

The event was in the form of a combination of "on-site observation + exchange and discussion", focusing on the innovative practice and application results of Sany unmanned compaction technology in the construction of highway asphalt pavement.

The Guangdong Provincial Observation Group went deep into the construction site of the K12+400 to K12+800 sections of the Jingqing Expressway and stopped to watch the unmanned paving and rolling collaborative operation. One 13-meter unmanned paver and four 13-ton unmanned tandem rollers deployed on site are all unmanned, and the roller group and the paver work closely to achieve "keeping up with slow pressure" and fully ensure the asphalt rolling temperature. At the same time, in strict accordance with the rolling process, the "centimeter-level" precise control can not only effectively avoid leakage and underpressure, but also achieve "0" welt rolling, effectively ensuring the quality of construction, and triggering many guests to stop and shoot and have warm exchanges.

At the subsequent academic exchange seminar, representatives of Anhui Construction Engineering Group introduced the project management experience and the application effectiveness of unmanned paving technology, and highly recognized the construction performance of Sany UAV swarm. Representatives of Sany Pump Road shared special topics around unmanned pressure palletization technology. The guests at the meeting conducted in-depth discussions on core issues such as equipment adaptability and construction economic benefits based on project practices in various places.

As a model of intelligent construction, Sany unmanned pallet press group takes global collaborative scheduling, fusion perception positioning, high-precision path tracking and group control security as its core technologies, showing the following advantages:

1. Standardized intelligent construction:After entering the process parameters, the standardized operation path is automatically generated, and the equipment realizes gentle start-stop and steering, and the rolling flatness performance is excellent.

2. Dynamic collaborative scheduling:The system dynamically adjusts the operation of the fleet according to the optimal path and real-time construction progress, accurately controls the number of lap and rolling passes, and avoids overpressure or undervoltage;

3. Multiple security guarantees:It is equipped with safety protection systems such as visual and radar fusion obstacle avoidance, electronic fence and safety scheduling to achieve intelligent collision avoidance;

4. Efficient human-machine collaboration:Realize "one person, one tablet" to control multiple equipment, reduce on-site operators by more than 60%, and also support 24-hour operation, significantly reducing on-site operators and construction cycles.

This observation meeting is not only a concentrated display of the achievements of in-depth cooperation between Anhui Construction Engineering and Sany Pump Road in the field of intelligent construction, but also an important industry activity for the first systematic investigation of unmanned and intelligent assembly technology in pavement construction in Guangdong, and has built a high-value platform for cross-regional technical exchanges and industrial upgrading.

All participants agreed that Sany unmanned compaction technology has wide applicability and important promotion value, and will actively promote the pilot and application of this technology in road construction projects in Guangdong Province in the future. This event provides a replicable and generalizable practical example for the digital transformation and high-quality development of our country's transportation infrastructure construction, and has important demonstration significance and far-reaching impact on promoting the construction of smart transportation in South China.

0 comments