CCTV's 11-minute special report, Sany Renewable Energy interprets the new connotation of "Made in China"

2025.10.29

As the scale of new installed capacity of China's wind power reaches the top of the world, innovative forces from the East are also reshaping the traditional wind power manufacturing model and realizing the evolution from "crowd tactics" to "human-machine collaboration".

On October 26, three episodes of the "Economic Information Network" column of CCTV Financial Channel were released, focusing on the "lighthouse factory" of Sany Renewable Energy Shaoshan blades, with an 11-minute special report, deeply decoding how this factory redefines the value and ability model of "industrial workers" with digital empowerment and human-machine collaboration, and while innovating the working environment, it achieves a leapfrog improvement in production efficiency and manufacturing accuracy, and creates a new core competitiveness in global competition.

Original report

At present, the super-large-scale engineer dividend and the talent supporting system of the whole industry chain have become an important development advantage for our country. Next, let's get to know two industrial workers and see how our country promotes the transformation of the "demographic dividend" to the "talent dividend".

Lu Zhonglin is an "old wind power man" who has been deeply involved in the industry for 17 years. He told us that in the past, the production of blades, from laying, pouring, molding to post-processing, required a lot of manual cooperation to complete, which also led to the fact that sometimes the consistency of product quality was difficult to guarantee.

Lu Zhonglin, deputy director of the Process Technology Institute of Sany Renewable Energy Shaoshan Blade Factory Technology: (Sany Renewable Energy) has been aware of this problem in the industry since the establishment of the factory in 2022, so it has introduced a series of automated and intelligent equipment to empower our blade manufacturing.

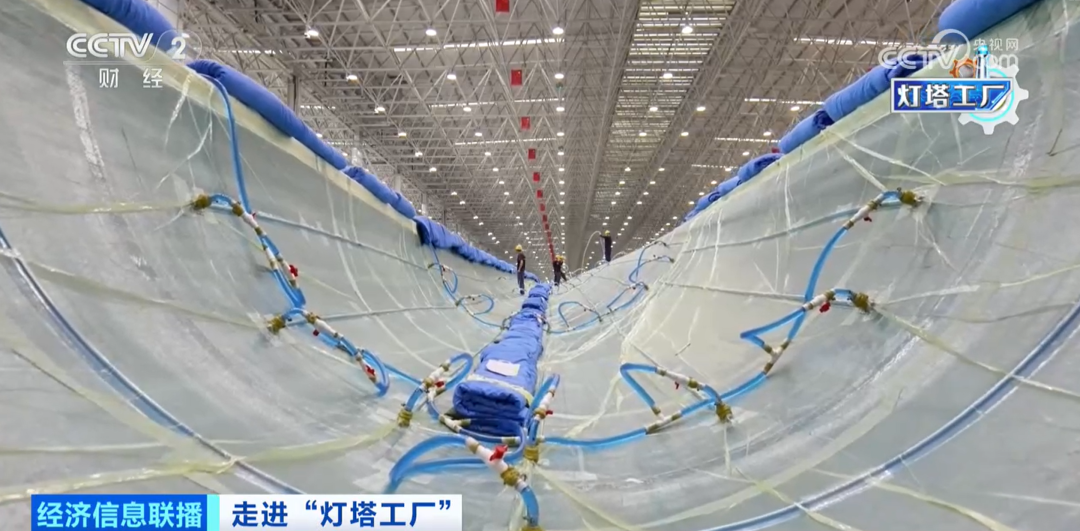

Under his guidance, we saw the centralized perfusion equipment. The infusion process of the blade is similar to "industrial infusion", which is to inject resin into the blade skeleton through vacuum and gradually penetrate into the glass fiber cloth, which can give the blade a strong "muscle" force after curing.

Lu Zhonglin, deputy director of the Process Technology Institute of Sany Renewable Energy Shaoshan Blade Factory Craft Institute: Compared with the traditional mobile glue machine, it will be more accurate and more convenient. For our 118 (m) leaves, the infusion is generally about 2 and a half hours to 3 hours. It used to be about 3 hours to 3 and a half hours. In terms of these auxiliary materials, the use of materials can be reduced by about 20%.

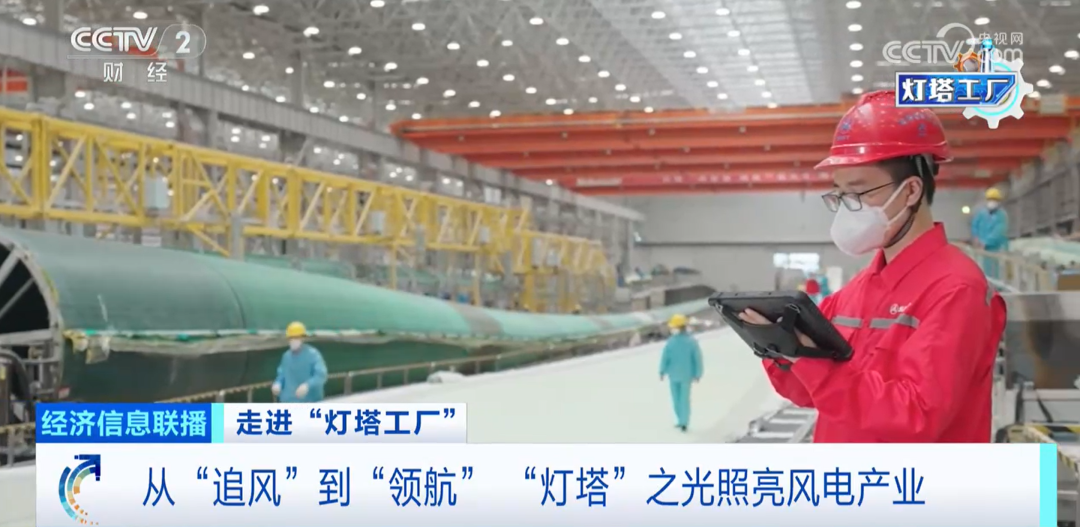

Traditional jobs have been given new content by the times, and a new generation of employees are actively integrating into this intelligent production environment. As a worker in the post-processing workshop, his main job is to let the robotic arm accurately polish the wind turbine blades under the guidance of the laser by inputting parameters.

Zhou Yaoting, junior worker of Sany Renewable Energy Shaoshan Blade Factory: When I first entered the factory, I trained for about a month, and when I first saw this machine, I also took a picture with my mobile phone, which was still advanced and high-tech.

In this lighthouse factory, new employees like Zhou Yaoting no longer rely on physical strength and repetitive labor, but work in collaboration with robotic arms, laser guidance systems and digital platforms.

Zhou Yaoting, junior worker of Sany Renewable Energy Shaoshan Blade Factory: At the beginning, it took three or four hours for 8 people to manually polish this blade, but now one person operates a machine, and it takes only two or three hours for a blade to be knocked down, which saves a lot of efficiency and time.

In addition, the factory has also independently developed a quality digital system, which carves a complete "digital context" for each leaf and establishes a new paradigm of traceable and optimized manufacturing.

Lu Zhonglin, deputy director of the Process Technology Institute of Sany Renewable Energy Shaoshan Blade Factory Craft Institute: In the past, we would have a paper record of hundreds of pages from blade production to delivery, so through our system, we are completely paperless, and every important parameter of our blades will be reflected in the system.

From "manufacturing" to "intelligent manufacturing", talent is the core engine. In recent years, factories have been improving manufacturing efficiency while redefining the value and ability model of "industrial workers".

Zhou Yaoting, junior worker of Sany Renewable Energy Shaoshan Blade Factory: Human-machine collaboration, I rely on it, and it also depends on me. In the future, there will definitely be more new technologies in our factory, and I am still willing to learn those new things and accept new changes.

Peng Haibing, deputy general manager of Sany Renewable Energy Shaoshan Blade Factory: The Shaoshan factory has a total of more than 700 employees, and it is very important to do a complete set of training system for front-line employees after the fixed posts, which is very important to facilitate (employees) to fully participate in digital collection and data management.

CCTV reporter Yang Ziwei: Standing in the workshop of Sany Renewable Energy's blade factory, I saw that the centralized infusion system allows the resin to be accurately injected into the mold like an infusion, and the automatic grinding of the robot makes the blade flatness higher, saving about 75% of labor costs. Here, the wisdom of craftsmen has never disappeared, but has been precipitated on a digital platform as a replicable and optimized algorithm.

In recent years, our country has continued to achieve breakthroughs in key technologies in the field of wind power, the process of wind turbine large-scale has accelerated, and offshore wind power technology has been continuously innovated. In 2024, our country's wind power output value will account for 64% of the world's total, and Chinese-made wind turbines will not only supply a large number of wind turbines to the domestic market, but also export to more than 50 countries and regions. The light of the lighthouse not only reflects efficient intelligent production and supply chain coordination, but also the complete trajectory of China's wind power industry from "catch-up" to "leader".

Rail mounted container gantry crane automation

Rail mounted container gantry craneRecommended products

0 comments