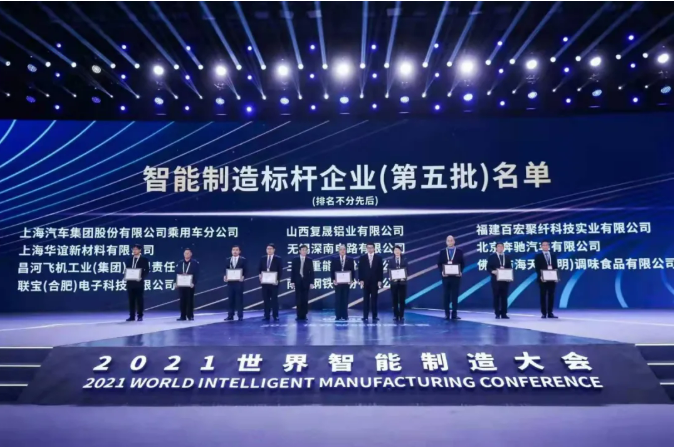

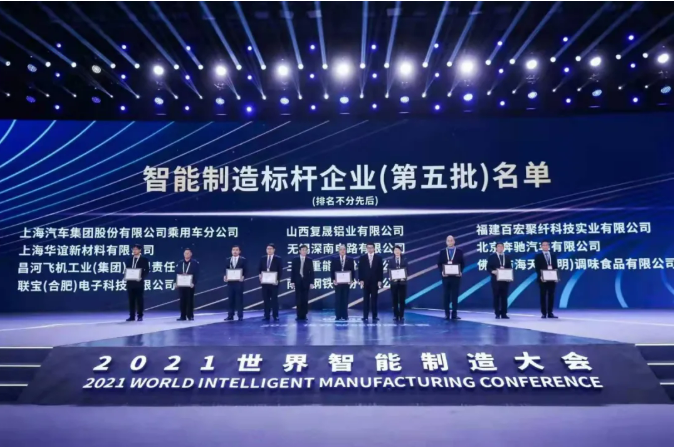

Today, the "2021 World Intelligent Manufacturing Conference" opened simultaneously online and offline in Nanjing, Jiangsu Province.At the meeting, the list of "2021 Intelligent Manufacturing Benchmark Enterprises" was officially announced, and Sany Renewable Energy was successfully selected. Peng Xu, digital director of Sany Renewable Energy, attended the conference on behalf of the company and took the stage to receive the award. This honor is a "golden signboard" in the field of intelligent manufacturing, which means that Sany Renewable Energy's intelligent manufacturing has reached the international first-class level. It is worth noting that the list has been selected and announced in five batches, and Sany Renewable Energy is the first enterprise in China's wind power industry to receive this honor.

The "2021 World Intelligent Manufacturing Conference" is jointly sponsored by the People's Government of Jiangsu Province, the Ministry of Industry and Information Technology, the Chinese Academy of Engineering, and the China Association for Science and Technology, with the theme of "Digital Transformation and Intelligent Leadership", which has become a vane leading China's intelligent manufacturing.The "2021 Intelligent Manufacturing Benchmark Enterprise" has 8,000 enterprises across the country participating in the application and self-assessment diagnosis, 130 enterprises have entered the final review, and 11 enterprises including Sany Renewable Energy have been finally selected. Standing out from many enterprises across the country also fully reflects Sany Renewable Energy's super strength and level in the field of intelligent manufacturing.

Over the years, Trinity Renewable Energy has been able to use "Intelligent manufacturing leads the futureAs a mission, we will continue to deepen our cultivation in the field of wind power intelligent manufacturing, introduce advanced intelligent manufacturing technologies and concepts, accelerate digital transformation, and strive to build a "lighthouse factory" that leads the global wind power intelligent manufacturing.

Adhering to the concept of "Made in China 2025" and "Industry 4.0" Internet of Things and informatization, Sany Renewable Energy has built an overall digital solution for high-end wind power manufacturing in terms of automation of complete machine and blade production lines, equipment integration, intelligent production, visualization of operation and decision-making of operation, etc., to achieve a high-quality, efficient, low-consumption, clean and flexible digital production system, and lead the high-end wind power manufacturing industry by establishing a 5G fully connected intelligent manufacturing lighthouse factory.In terms of production line automationThrough the integration of robot application and lean production system, Sany Renewable Energy has created an industry-leading "pulsating" production system with flexible production capacity. At the same time, intelligent robots are used to replace manual labor in key processes to improve production efficiency and assembly quality reliability. In key processes such as pitch, yaw, transmission chain, cable, material distribution, etc., the combination of six-axis robots, vision systems, optoelectronic systems, hydraulics, pneumatics, servo control, automation control, AGV, network interconnection and other advanced technologies has realized a fully automated and unmanned production unit, which greatly improves the safety, quality reliability and production efficiency of production.In terms of the Internet of ThingsThrough camera visual recognition technology, Sany Renewable Energy comprehensively monitored the on-site production 6S, on-site personnel safety and attendance, on-site material use and storage, and uploaded it to the Sanxian platform for intelligent analysis; Through the installation of smart water meters, electricity meters, gas meters and the application of IoT technology, the collected water, electricity and gas information will be intelligently analyzed, and the energy consumption of enterprises will be reduced through the analysis of abnormal or peak energy consumption situations. Through the data collection of workshop equipment through IOT technology, the real-time database and historical database are established, and the integrated application of the data acquisition system and digital information platform collects workshop production, quality and equipment information in real time, so as to achieve accurate and rapid analysis, decision-making and response, so as to achieve zero-carbon green manufacturing.In terms of production intelligence,Through the construction of intelligent manufacturing information system system, the application and in-depth cooperation of PLM, ERP, MOM, WMS, QIIS and other information systems are used to realize the integration and opening up of factory data, and on this basis, provide more efficient information transmission, production management and collaboration. Realize the accurate issuance of workshop plans to workers, and collect the actual processing progress in real time, change the traditional working mode of manual statistics, solve the disconnection between the planning and actual production of traditional manufacturing enterprises, and improve the execution management of the workshop.In terms of data visualization and digital operations,Through the integration of the excellent performance indicator system, the use of data center and big data technology, based on the big data platform to create a set of visual operation system covering marketing, service, production, quality, procurement, and human resources, through the visualization of operation and production data, the transformation from the traditional management mode to the digital operation mode is realized, and the digital decision-making is realized. At the same time, through the collection of wind turbine data, the use of data modeling and the application of big data, the predictive preventive maintenance and digital monitoring system of wind turbine operation are realized, and the transformation of the digital operation and maintenance system is realized.

0 comments