Today, let's talk about the intelligent compaction technology of asphalt pavement

2022.01.19

Trinity Road machine

In the past 20 years, China's highway construction has developed rapidly, and the mileage of highways in the country has reached now1510,000 kilometers, the country's investment in highway construction still maintains a trend of increasing year by year.

However, the existing construction compaction operation mainly depends on the experience level of the operator, and the monitoring of the number of compaction times in the construction process is limited, and the situation of leakage and overpressure is easy to occur. The compactness detection of the finished product is also mostly carried out by the method of spot inspection, and the detection results often cannot truly and objectively reflect the compaction quality of the whole road section, and the inspection method of core pulling will also lead to the damage of the complete road surface.

Therefore, it is very necessary to introduce new technical methods to obtain pavement compaction process data in a timely manner, and shift the post-inspection of construction quality to the scientific management mode of in-process control, so as to further improve the level of engineering construction quality management.

Conventional construction asphalt layer core-pulling to detect the degree of compaction

Continuous compaction monitoring system

01Process principle

To ensure that the asphalt pavement compaction is qualified, the most direct and effective process control measure is to strictly implement the compaction process according to the requirements, in the case of qualified raw material quality, one is to ensure the mixing and amortization temperature, and the other is to ensure the compaction times of each point of the whole road section.

Conventional construction relies on manpower to monitor the temperature of incoming asphalt and the number of compaction times, low efficiency, high error rate, and unmanned monitoring occurs during night construction, which can easily lead to underpressure or overpressure on the pavement and affect the quality of the finished product.

The intelligent compaction technology researched and developed by Sany Group adopts compaction parameters such as the number of pavement rolling passes, compaction degree, temperature and so on-line in real time, and can guide the operator to adjust the rolling trajectory, amplitude, walking speed and other key mechanical parameters in time during the construction process, so as to improve the uniformity of compaction, thereby improving construction efficiency and compaction quality.

02System principle

Sany Group's intelligent compaction technology is through the inroad rolleron-line detection and real-time feedback system.

In the process of pavement compaction, according to the principle of mutual dynamic action between the pavement and the vibrating roller, combined with the high-precision positioning system and the temperature measuring device, the process parameters such as the pavement compaction, position trajectory and temperature of the roller are continuously measured in the operation process of the vibrating roller, and through the establishment of the detection evaluation and feedback control model, the operator is guided to adjust the rolling parameters in real time, so as to realize the real-time dynamic detection and control of the compaction quality of the entire rolling surface.

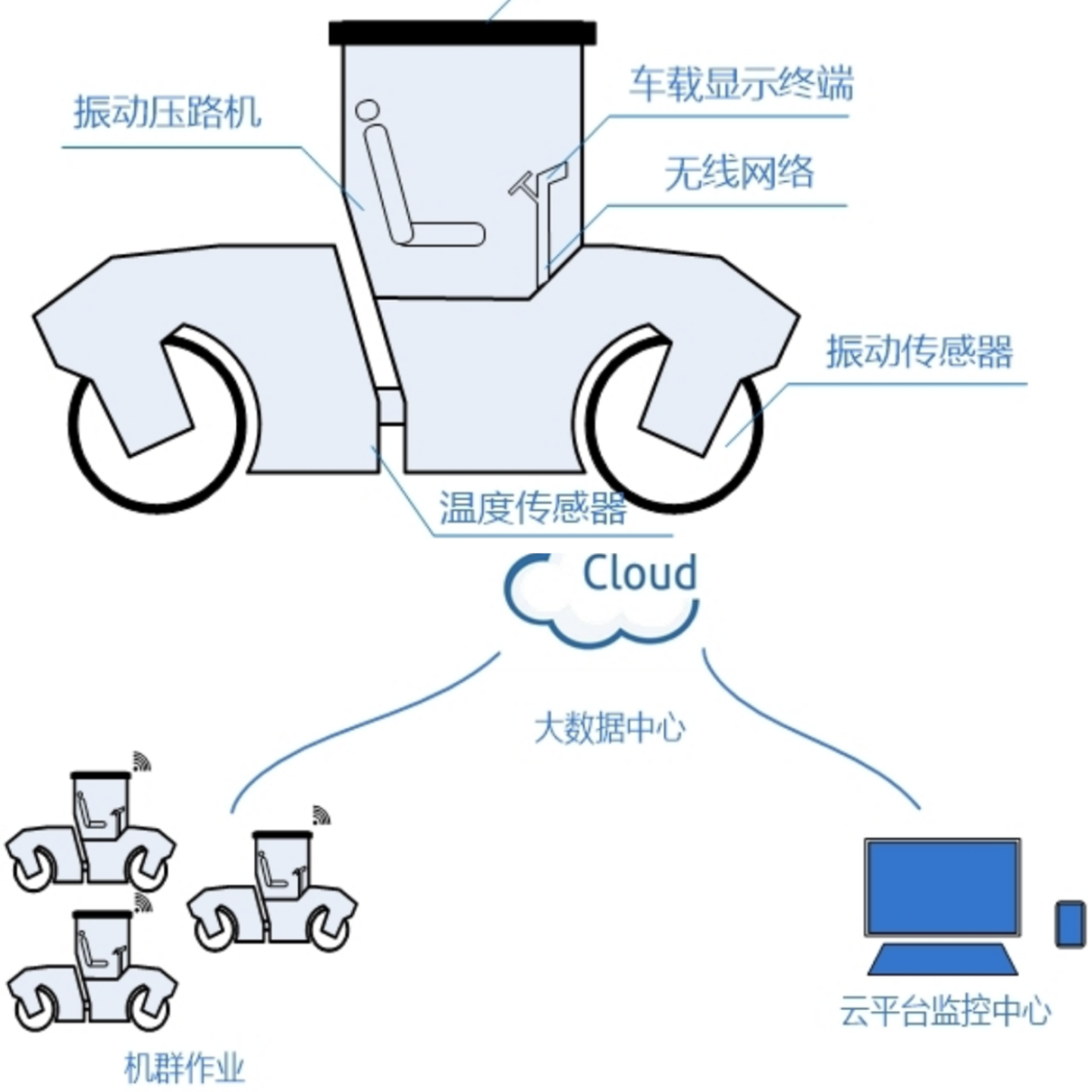

03System composition

The intelligent compaction system mainly includes vibrating rollers, high-precision positioning antennas, wireless networks, on-board display terminals, vibration sensors, temperature sensors and big data cloud platforms.

Vibration sensor: In the working state of the vibrating roller (vibration on), the real-time feedback information of the pavement of the position of the vibrating drum is collected, and converted into the pavement compaction value through the Fourier transform.

The temperature sensor is used to collect the temperature information of the current roller position and provide a temperature distribution map for high-temperature rolling of asphalt pavement construction.

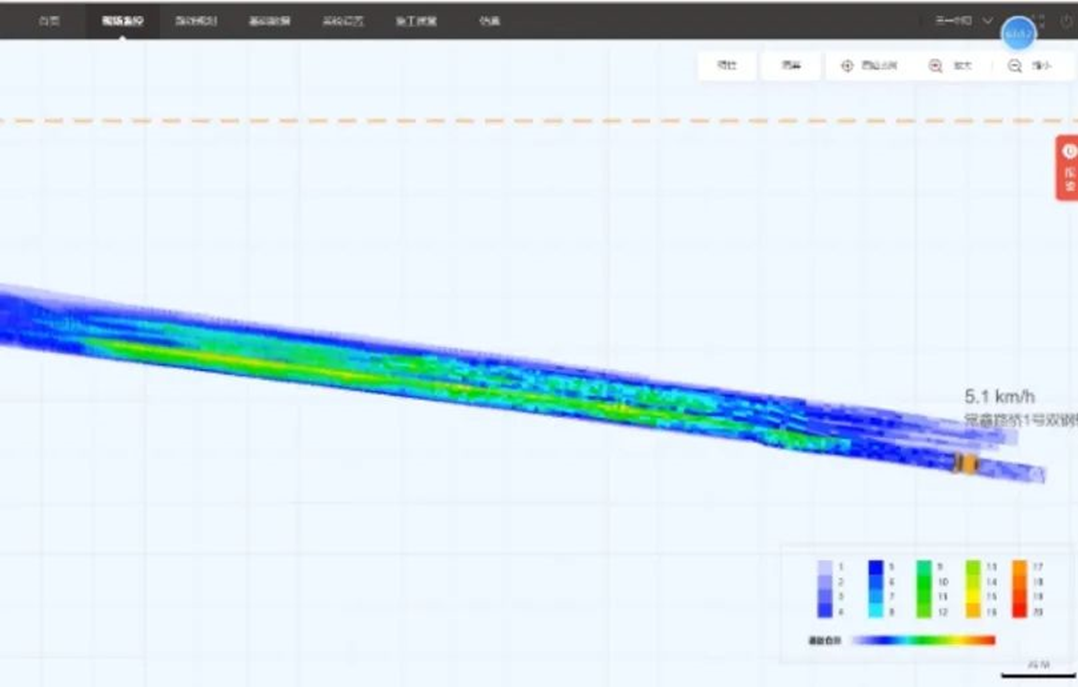

The cloud platform data center is connected to the sensors mounted on the roller through the wireless network, collects and processes the pavement data information in real time, and converts it into an intuitive visual color scale diagram, which clearly displays the compaction data information of the current vibratory roller location, mainly including compaction, pass, temperature, mechanical speed, vibration frequency, amplitude, coordinates, etc. And it is presented to the operator through the vehicle terminal on the roller to guide the operator's operation.

At the same time, through the data sharing of the cloud platform, remote monitoring of construction can be realized, which is convenient for management personnel to macro-control the quality and progress of the project.

The intelligent compaction system can adopt the mode of single machine operation and group cooperative operation to adapt to different working conditions.

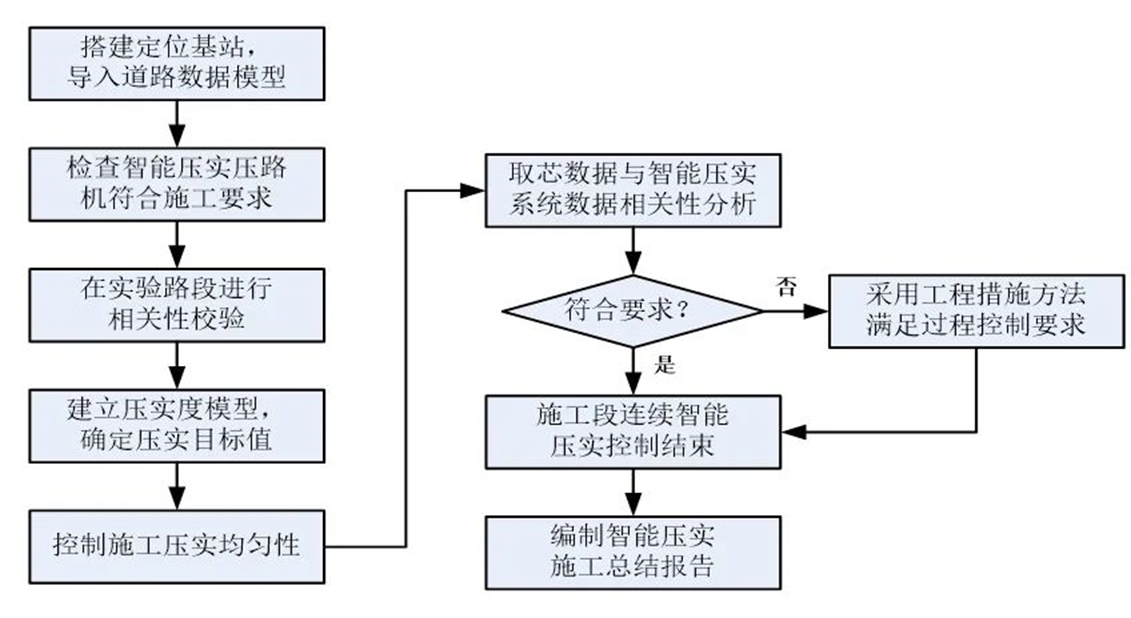

04Procedure

The operation process of the intelligent compaction system is as follows:

Engineering applications and effects

01Project Overview

Sany Group's intelligent compaction technology was established in a highway in Nanjing (hereinafter referred to as“Nanjing Expressway”The upper layer is implemented and applied in the construction, altogether5The rollers are equipped with an intelligent compaction system and the asphalt material layer is used in the construction sectionSMA-13S, the compaction thickness is4cm, the total length of the implementation section34kmIt is a two-way split uplink and downlink4Lane.

Intelligent compaction system construction

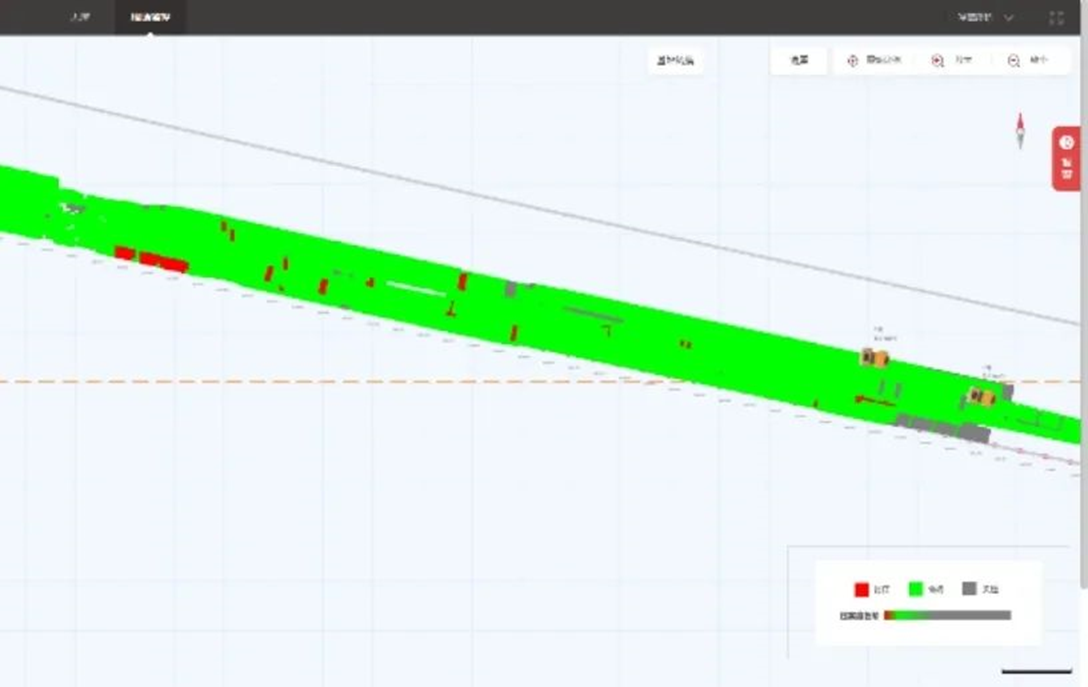

Compaction color scale diagram of the interface of the vehicle display terminal

Chromatic scale diagram of the distribution of compaction passes

02Analysis of experimental results

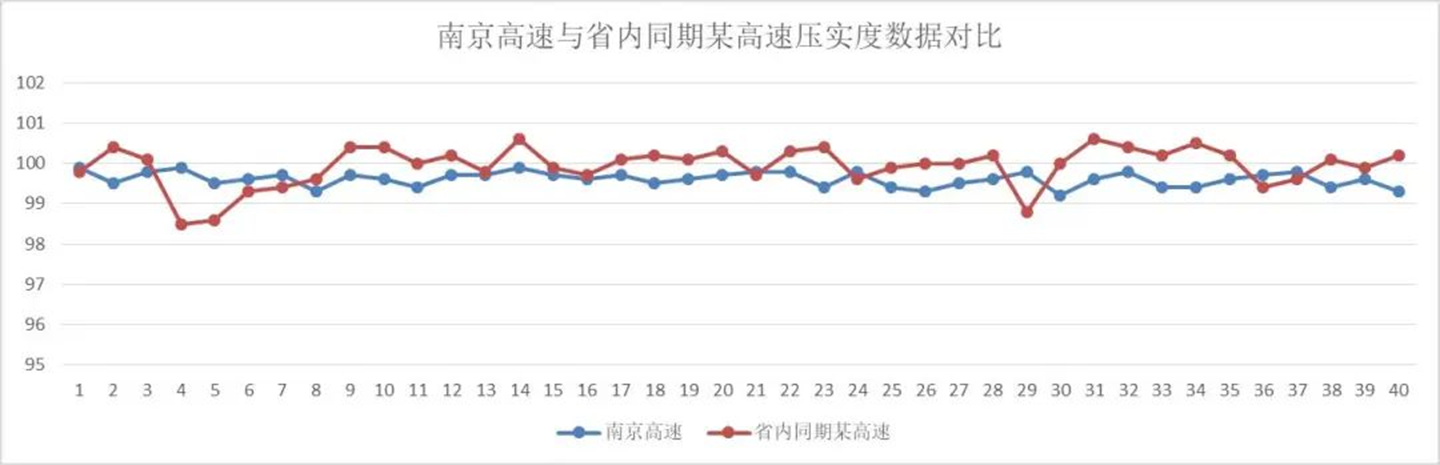

Comparison of compaction data of Nanjing Expressway and a high-speed in the province in the same period

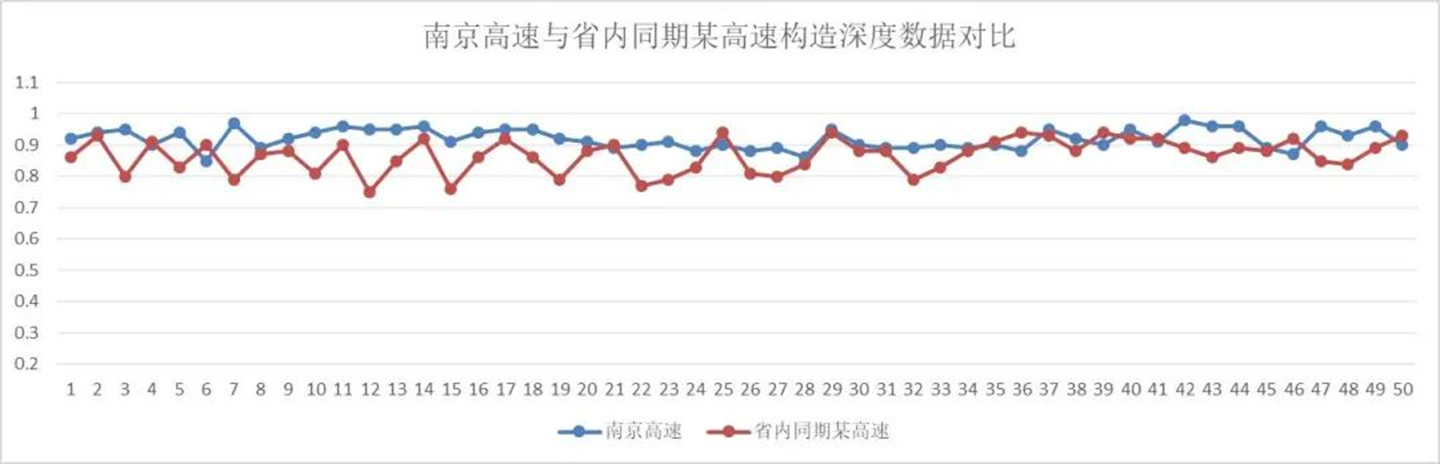

Comparison of the structural depth data of Nanjing Expressway and a high-speed in the province in the same period

After construction, the coring and structural depth of the construction section were tested, and the experimental data of a high-speed in the province during the same period were compared, as shown in the previous figure.

The results from the experimental data show that the use of Sany intelligent compaction technology can fully ensure the reliable implementation of the compaction process, and the discrete degree of compaction and structural depth of the construction high-speed is smaller and the uniformity is better, and the key indicators are better than the data of a high-speed section in the province in the same period.

This is because in the process of roller vibration rolling through intelligent compaction data analysis, and through the on-board computer compaction color scale diagram real-time guidance of the roller driver to understand the road compaction situation, timely pressure on the pavement underpressure parts, in the construction process to effectively improve the compaction quality, so as to significantly improve the stability and uniformity of the entire pavement compaction.

ICVThe value is related to the number of passes

Through the analysis of the data of the number of rolling passes, it can be seen that with the increase of the number of rolling passesICVThe value increases to a certain extent with the number of passes, when the number of intelligent compaction passes of the roller reaches the first6After the repetition,ICVThe value tends to be stable, which means that the compaction value of the pavement has tended to be stable at this time. But with the further increase in the number of compaction passes, intelligent compactionICVThere will be a slight downward trend in the value, which should be caused by overpressure, so it passesICVThe change in value can also objectively reflect the compaction of the road surface.

Through the use of intelligent compaction technology, the pavement compaction parameter information can be continuously collected, and the compaction data can be presented in the form of color scale diagrams, which can guide the operation of the roller operator in real time, effectively prevent underpressure and overpressure, improve the uniformity and quality of pavement compaction, improve compaction efficiency and prolong the service life of the road.

In addition, the construction process can also be completely recorded through intelligent technical means, providing strong data support for the traceability of quality problems in the later stage and the improvement of construction technology.

The implementation of intelligent compaction technology needs to be tested on materials and processes in the test section, and good construction results are achieved through strict implementation of qualified construction parameters.

Related testimonials

"Magic Rock" is here! The industry's first full-scene electric heavy truck exclusive chassis platform

2025.05.28

Central media focus | "Science and Technology Daily" reported on the innovative practice of Sany heavy truck industry upgrading

2025.04.29

"Stepping on Ten Thousand Journeys to Be Reliable" Sany Heavy Truck Double High Test Promotional Video Shockingly Released! Only when it stands the test can it be trusted

2025.04.14

0 comments