Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Campaigns > The first batch of typical cases of new technologies and new products of intelligent construction innovation services|"Zhuxiang Cloud" construction industry Internet platform was successfully applied in the Sany Cloud Valley project

The first batch of typical cases of new technologies and new products of intelligent construction innovation services|"Zhuxiang Cloud" construction industry Internet platform was successfully applied in the Sany Cloud Valley project

2022.01.19

Trinity Construction

At the end of 2021, the General Office of the Ministry of Housing and Urban-Rural Development released the first batch of selected typical cases of new technologies and new products for intelligent construction.Trinity ConstructionTwo cases of Technology Co., Ltd. were selected. Among them, Sany Construction's "Zhuxiang Cloud" construction industry Internet platform was selected as a typical case of construction industry Internet platform. Today, let's take a closer look at the "Zhuxiang Cloud" construction industry Internet platform, which was rated as "the first batch of typical cases of intelligent construction new technology and new product innovation services".

1. Overview of the platform

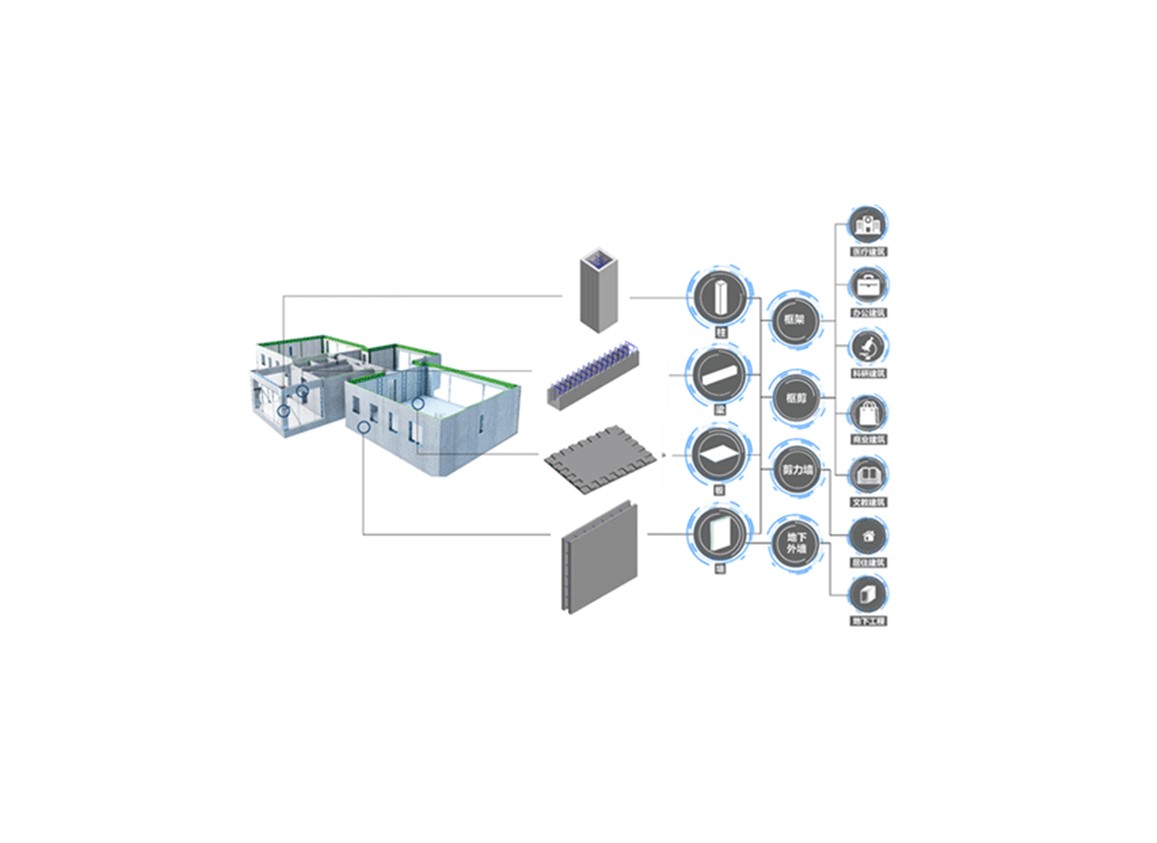

Relying on the industrial Internet technology of tree root interconnection, the "Zhuxiang Cloud" construction industry Internet platform has created an online collaboration platform of "full cycle, full role, and full element" of the project, which can provide digital overall solutions for intelligent construction. The platform includes five core modules: project management, detailed design management, component production management, on-site construction management, and BIM digital twin delivery, which supports users to carry out platform planning, customized design, digital factory automated production, digital site intelligent construction, one-yard twin delivery and data operation, which is conducive to the interconnection of the construction industry chain.

2. Project Overview

Sany Yungu Project is located in Sany Industrial City, Economic and Technological Development Zone, Changsha City, Hunan Province, with a total construction area of about 240,000 square meters, including a basement construction area of 51,000 square meters. The project is developed in three phases, the first phase of the first area consists of 4 high-rise buildings and 2 6-storey buildings, with an above-ground construction area of 57,798 square meters and a basement construction area of 13,000 square meters. Among them, Building 3 has a building height of 72.35m, a construction area of 11,626 square meters, an SPCS application area of 9,492 square meters, and a construction area of about 452 square meters per standard floor, using 38 laminated panels, 37 cavity walls, 4 superimposed beams, and 4 prefabricated stairs, with a total of 24 floors. The basement of the first opening area uses 42 superimposed columns and 26 cavity exterior walls. All components implement SPCS structural system standards, and are independently designed, produced, transported and hoisted by Sany Construction.

Figure 1 Project renderings

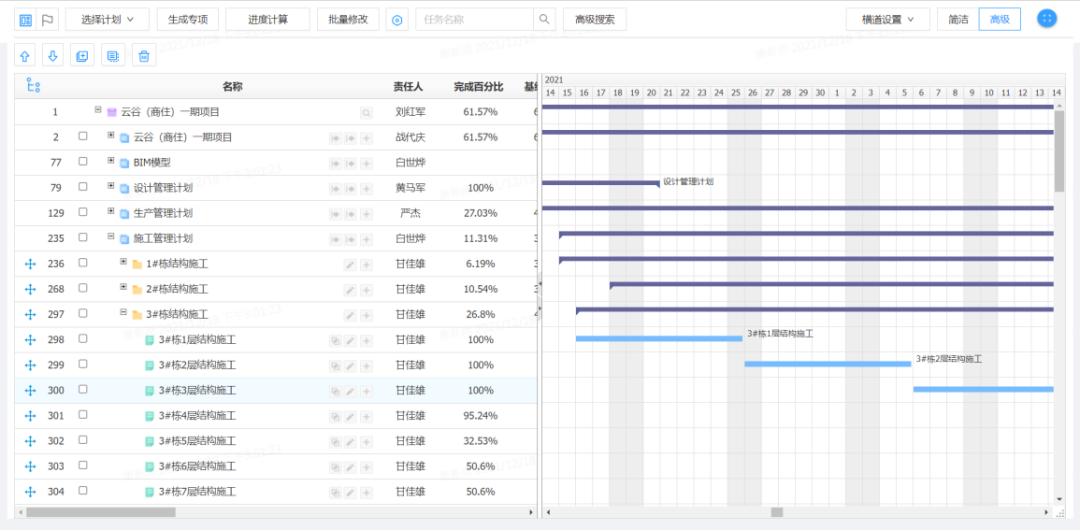

3. Project plan management

The Yungu project compiles and feeds back the project plan through the project management module, and combines the document results with the business workflow, so that all parties involved can be closely connected. The specific application is as follows:

Figure 2 Project plan management

(1) Efficient preparation of plans and real-time sharing of project construction progress. The general contractor prepares the overall plan of the project, and the component factory and the hoisting construction unit prepare the special plan for component production and hoisting construction respectively. Establish a linkage relationship between plans, and dynamically coordinate between production and construction plans. Timely feedback on the progress of the work by the mandate holder.

Figure 3 Feedback on the project plan

(2) Project data and document sharing. The general contractor shares the BIM model, component list and other data with all collaborating units through the platform, and all parties can quickly query the shared files through the mobile application.

(3) Comprehensive prompt and early warning function. The general contractor monitors the planned tasks through the platform, and automatically pushes the early warning information when the progress deviates, reminding the relevant responsible persons to pay attention to and deal with it, which effectively improves the planning efficiency and control ability of the Yungu project, and the plan management platform has become an important engine for project operation.

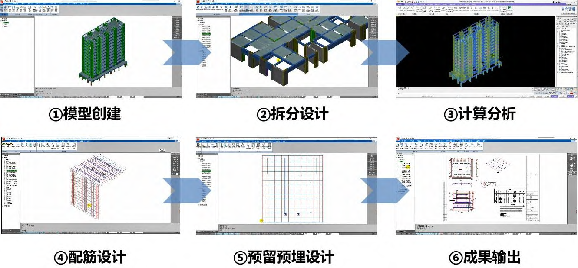

4. Deepen design management

The Yungu project used the detailed design tools provided by the platform to create the model, split the design, calculate and analyze, design the reinforcement, reserve the embedded design and output the design results.

Figure 4 The main process of deepening the design

5. Component production management

The Yungu project entrusts Hunan Sany Construction Engineering Co., Ltd. to produce components, and applies the production management module of platform components throughout the process to realize the whole process management of components in scheduling, production, quality inspection, storage yard and transportation.

(1) Planned-driven, the production process can be monitored

The Langli factory uses the platform production management module to prepare a production plan for the list of project components, and inspects and records each production link on the mobile terminal. Production status and quality data are shared in real time by all parties, and production progress and quality are tracked online.

(2) One piece and one yard, the whole process of digital twin

On the Yungu project, the Langli factory manages the components one by one code through the platform, binds each component with a QR code label, and connects the digital components with the physical components to achieve virtual and real synchronization.

Figure 5 One piece of one-yard card

(3) Data-driven automated production

The Langli factory uses the platform to analyze digital drawings, automatically schedule the production process, and complete the main links such as automatic marking, dismantling/layout mold, distribution, vibration, stacking, curing, flipping, and quality inspection through the manufacturing execution system. The equipment of the production line is intelligently interconnected, efficient and coordinated operation, and the production cycle of components is ≤ 8min.

Figure 6 Data-driven automated production

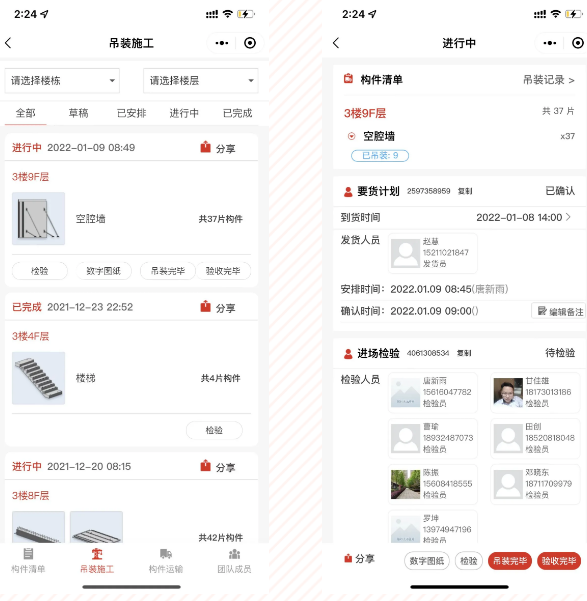

6. Project construction management

Based on the construction simulation of a single component, the digital construction management tools provided by the platform can realize the management of the whole construction process such as the coordination of goods, entry acceptance, hoisting construction, installation and acceptance, and realize the traceability of the whole life cycle of components and the delivery of BIM twins.

(1) Coordination of goods

The constructors of the Yungu project asked for the goods before the components were hoisted. The factory receives the information of the goods in real time, arranges the delivery according to the plan of the goods, and the components are sent from the factory, and the system intelligently identifies the transport vehicles leaving the factory and entering the project site, automatically changing the status of the transport order and notifying the relevant personnel in time. When the component transport vehicle arrives near the construction site, the constructor organizes the quality, material personnel and supervision to enter the site for acceptance of the component, and reasonably arranges personnel and machinery to prepare for unloading and hoisting.

Figure VII Component transport note

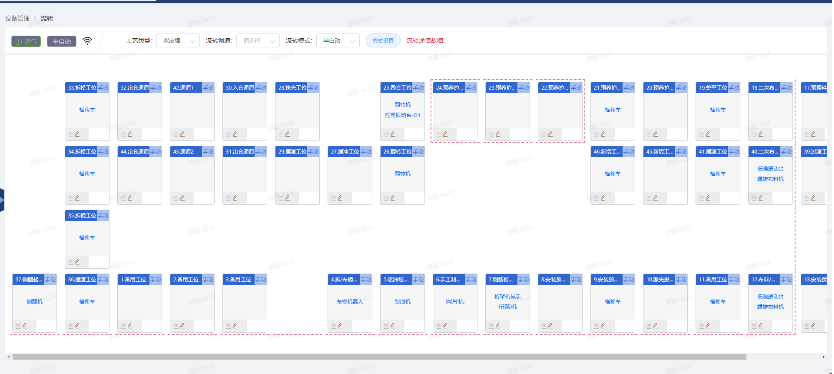

(2) Hoisting plan arrangement

The construction staff of the Yungu project arranges the hoisting plan according to the on-site construction progress. Issue the hoisting plan to the hoisting team through WeChat, arrange the construction personnel according to the planned hoisting time, and coordinate the tower crane to prepare for hoisting.

Figure 8 List of construction plans and details of construction plans

(3) Collaborative construction of hoisting

When hoisting, the hoisting personnel scan the code to identify the digital drawings, guide the floor construction, and intuitively locate the position of the components to be installed. The management personnel grasp the hoisting progress of the components on the floor in real time, count the hoisting time through the applet, continuously analyze the hoisting efficiency, and improve the hoisting process, so as to gradually improve the hoisting speed.

Figure 9 component hoisting code scanning

Figure 10 Digitized drawings

7. BIM digital twin delivery

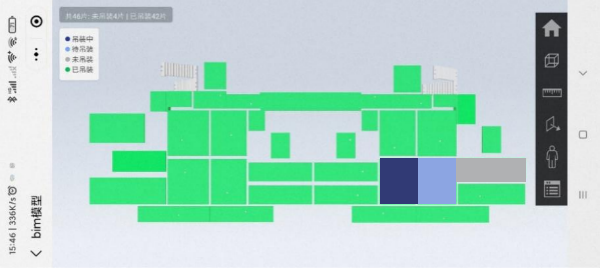

The BIM model designed by the Yungu project is connected with the production, transportation, construction and other links of the components, and the digital twin delivery goal is achieved. The component status is synchronized to the BIM model in real time, and the model is rendered in different colors, so that managers can control the construction progress in real time, reasonably arrange the interspersed processes, and improve the efficiency of construction delivery.

Figure 11 BIM digital twin delivery of Building 3

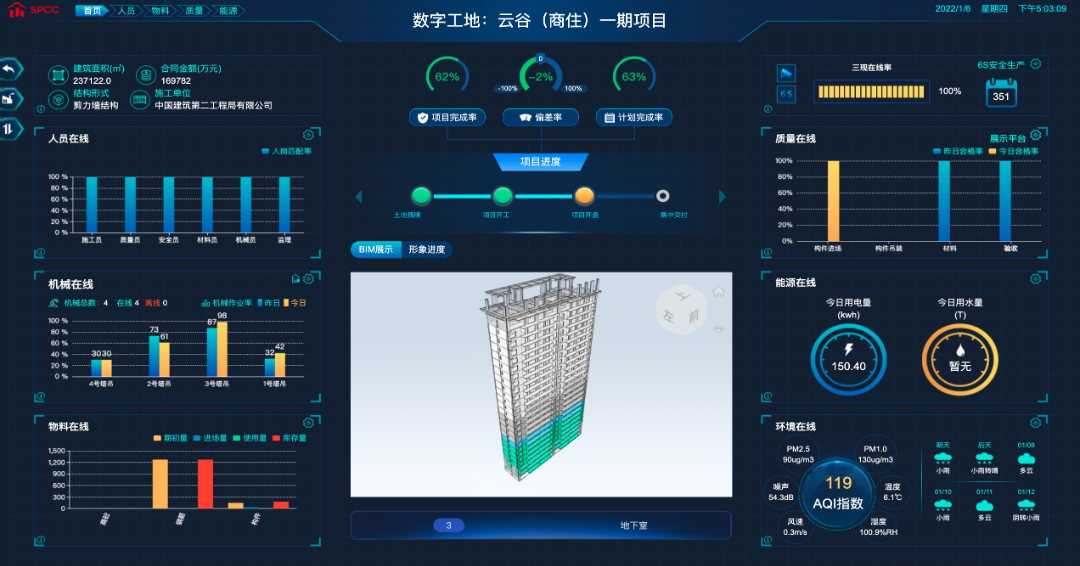

8. Digital construction site

During the construction process of the project, the network connection between the owner, supervision, construction and other roles is established through the digital construction site cockpit, and the component platform ecology is established. It can visually present the project overview and key indicators such as personnel, progress, quality, safety, and cost, and the project situation can be visualized.

The application of the "Zhuxiang Cloud" construction industry Internet platform has brought great convenience and technological empowerment to the overall management of the Yungu project, gradually projecting the on-site operation picture on the screen, and using digital scientific and technological means to show the project dynamics to the owners, supervisors, construction parties, and home buyers, becoming a benchmark model in the field of intelligent construction. With the continuous enrichment and optimization of application scenarios on the "Zhuxiang Cloud" platform, the process of "industrialization of buildings" will be further accelerated.

Figure 12 Digital construction site cockpit

Figure 13 Site 3 management

SPCS structural system

Structural standardsRecommended products

Next article:SKT105S|Hardcore King Kong, born with high energy!

0 comments

Related testimonials

Build the Greater Bay Area together|Sany rotary excavator group is in full swing to create a Shenzhen skyline

2025.06.26

Su Chao & Sany Dream Linkage, Exclusive Benefits Revealed!

2025.06.26

Sany Heavy Machinery's first overseas factory localized supply chain return training ended successfully!

2025.06.26

0 comments