The scientific research achievements of Sany construction equipment are "new" again! The scientific research achievements have reached new heights

2021.03.10

Construction time

December 2020

Construction site

The type of project

Housing construction

Device type

Trinity Construction

Patent authorization for a single scientific research project17 items, 3 inventions, and achieved a number of domestic initiatives, scientific research achievements to achieve intelligent analysis, intelligent production and intelligent delivery of steel bar parts/components, such Sany intelligent steel bar welded mesh production line technology development has not surprised you?

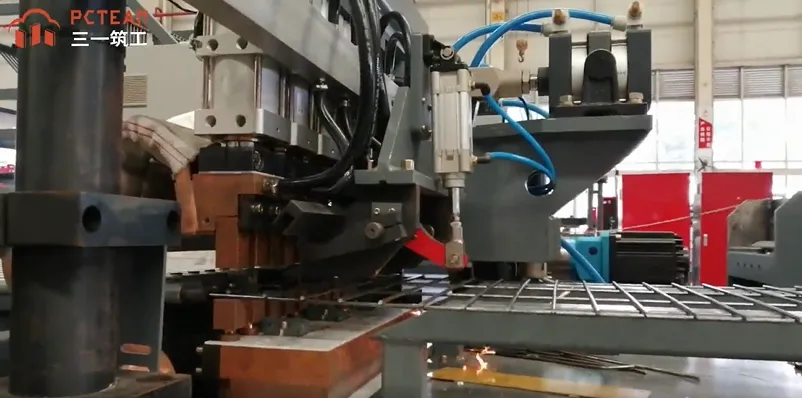

In 2020, the project of "Development and Application of Intelligent Welded Wire Mesh Technology for Prefabricated Building Parts" undertaken by Sany Construction Engineering successfully passed the acceptance, and the project developed the first (set) intelligent welded steel mesh series production line in Hunan Province, covering PC production line and ALC production line, and can be customized according to the actual needs of the project. The first domestic steel welded mesh production line control system SPCI-RMES (hereinafter referred to as SPCI-RMES) is adopted, which seamlessly connects and integrates the tasks of PC and ALC production lines to realize the production, distribution and installation of steel bar JIT. Today, the technology has been promoted and applied in more than 10 projects across the country, and the hard-core technology continues to lead the steel processing equipment industry.

![]()

It is reported that the project has applied for core technology patents35 patents, 17 patents have been authorized, including 3 inventions, 2 core papers, and 2 technical standards/procedures, which effectively overcome the problems of slow speed, annoying management, poor accuracy and waste in the traditional welded steel mesh industry, and realize the intelligent analysis, intelligent production and intelligent delivery of welded steel mesh.

1. Intelligent analysis

The production line management system of concrete prefabricated components independently developed by Sany can be correctedThe BIM components are automatically split, and each component is marked with a specific sub-component identification code, which is bound to the assigned mold table, and the SPCI-RMES identification mold table drives the fully automatic operation of the mesh welded mesh production line. In addition, the component factory can automatically complete the assembly of components on the mold table according to the delivery requirements.

2. Intelligent production

Sany steel bar welded mesh production line is the first in ChinaThe 9-meter-wide mesh machine can be started with one key through the welded mesh master console, and the control and management of the steel bar welding system, tensioning, net transportation system, and straightening/longitudinal/transverse bar conveying system can be realized through SPCI-RMES, so as to realize the automatic operation of the equipment.

Among them, the steel bar welding system pioneered the double transformer arrangement, which can automatically detect the solder joints, and realize intelligent start and stop through the cooling system. The pulling and transportation system adopts the patented technology of flexible net pulling, and can realize the intelligent displacement of the mesh and the intelligent positioning of the network. The straightening and longitudinal and transverse rib conveying system adopts the first domestic dual-module combined straightening system and high-efficiency distribution transverse rib device, which can realize the functions of automatic rolling, adaptive clamping, and intelligent detection.

The control management system can be based on:The rebar component model output by PKPM, PlanBar and CAD directly drives production, and realizes the intelligent data interaction of the central control room, mold table, circulation, mesh machine and net grabbing equipment, intelligently extracts the mesh data in the component model and analyzes it into a specific code, and uses the mesh data to drive the automatic production of welded mesh equipment through SPCI-RMES.

3. Intelligent delivery

SPCI-RMES drives the mesh machine with the position data of the mesh mold table to realize the automatic steel mesh shift production, and the screen grabbing equipment can intelligently extract the production data of the mesh machine and the circulation of the die table, intelligently execute the production tasks according to priority, and use the location sharing data and intelligent shift production functions to realize the accurate delivery of the net grabbing equipment.