In March 2019, Sany Road Machinery Shining G105 Beijing-Macao Line Construction Observation Meeting

2021.09.23

Construction time

March 2019

Construction site

Shandong

The type of project

earthwork

Device type

Road machinery

March 22,Sany Heavy Industry's SSR330C-6 single-drum dual-drive roller equipped with unmanned driving technology, and the Sany STG190C-8 motor grader equipped with Moba's 3D intelligent leveling system,Unveiled at the site of the reconstruction project of the Pingyin Ring Section of the G105 Beijing-Macao Line.

▲The site of the construction observation meeting

The project is undertaken by Jinan Tongda Highway Engineering Co., Ltd., with a total length of 12.4 kilometers, using first-class highway standards, and more than 100 people from relevant units, business owners, supervisors and customer representatives in the field of highways and transportation in Shandong Province and Jinan City participated in the observation meeting.

▲The site of the construction observation meeting

In the on-site demonstration of the equipment, Sany Heavy Industry demonstrated the automation and intelligence of road machinery, and frequently won the praise of the on-site visitors. It is worth mentioning that this isSany unmanned roller was delivered to the customer for the first time for application in the actual working conditions of the highway field。

Sany STG190C-8 grader construction operation

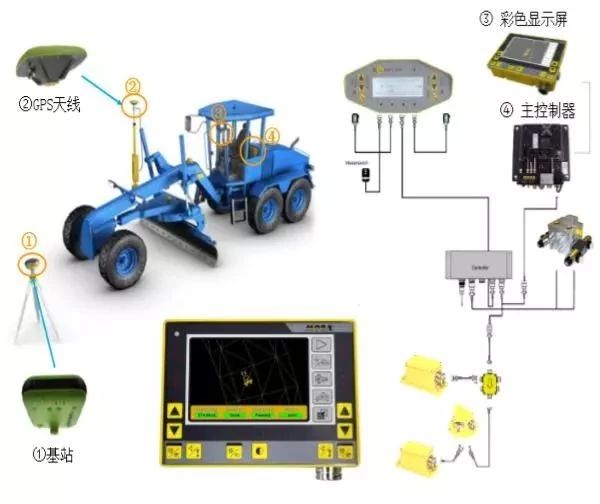

At the site of the construction observation meeting, the Sany STG190C-8 grader equipped with Moba's 3D intelligent leveling system worked under the precise positioning of satellite GPS, and automatically extracted information such as the road surface elevation of the pre-input system.

▲System schematic

After system processing, it is fed back to the hydraulic module, which controls the lifting of the shovel lifting cylinder, so as to realize the function of automatic leveling.

▲Sany motor grader operation

Its use will greatly reduce the number of operators, from the original technician to measure the elevation and mechanical leveling to the grader automatic levelingIt simplifies the process, is more efficient and intelligent, and can save a lot of costs in manpower and material resources.

Sany unmanned roller construction operation

As an unmanned intelligent roller delivered to customers for the first time, it is equipped with an intelligent compaction system on the basis of Sany's 33-ton vibrating roller, which completely changes the constraints on drivers and construction environment in the previous construction, and truly realizes "group control construction" and "unrestrained".

▲System schematic

The construction area and construction standards are set through the monitoring room, and the dashboard of each vehicle is monitored in real time, making the control more convenient and accurate. Set up early warning areas and intelligent anti-collision equipment for cluster operations, so that the safety factor is greatly improved.

▲Sany unmanned intelligent roller

It can work safely at 45 degrees Celsius and at night, solve the problems of leakage, undervoltage, tower connection, and inconsistent edge construction, the degree of compaction can be checked at any time, the data can be traced, and the construction quality report can be automatically generated, which can easily meet the requirements of standardized operations.

Related testimonials

10-meter paver construction case|SAP90C-10S helps Hunan Changzhu Expressway rejuvenate!

Sany unmanned amortizer group is fully applied in the 02 bid section of Xuhuaifu Expressway

Road machine construction case | Kuitun Tacheng Street Municipal Project

UAV swarm construction case | Xuhuaifu pavement 02 bid section project