Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

What does intelligent manufacturing bring to the wind power industry?

2022.01.21

CWEA

Promoting the intelligent transformation of manufacturing links is regarded as a key fulcrum for wind power enterprises to enhance their competitiveness.

The latest example of the electricity industry's efforts to improve the level of digitalization and intelligence is Sany Renewable Energy Co., Ltd. (hereinafter referred to as "Sany Renewable Energy").

On December 8, 2021, the "2021 World Intelligent Manufacturing Conference" opened. In the list of "2021 Intelligent Manufacturing Benchmarking Enterprises" announced at the meeting, Sany Renewable Energy stood out from 8,000 participating companies across the country and successfully ranked among the 11 selected enterprises, and it is also the only enterprise in Beijing and China's wind power industry to receive this honor.

It is reported that in April 2019, under the guidance of the Ministry of Industry and Information Technology, the selection of "Intelligent Manufacturing Benchmarking Enterprises" was launched, aiming to select a group of enterprises with outstanding results in intelligent manufacturing, industry representativeness and demonstration effect, and lead the transformation and promotion of China's manufacturing industry from point to line to surface intelligent manufacturing through excellent typical cases of digital transformation and intelligent upgrading. Up to now, a total of 37 "intelligent manufacturing benchmarking enterprises" have been selected across the country. With its excellent performance in the field of intelligent manufacturing, Sany Renewable Energy has become the fifth batch of "Intelligent Manufacturing Benchmarking Enterprises".

In recent years, with the development of a new generation of information technology such as big data, cloud computing, Internet of Things, artificial intelligence, etc., a new round of industrial revolution with networking, digitalization and intelligence as the core has swept the world. The "14th Five-Year Plan for the Development of Intelligent Manufacturing" proposes that by 2025, most of the manufacturing enterprises above designated size will be digitized and networked, and the backbone enterprises in key industries will initially apply intelligence; By 2035, manufacturing enterprises above designated size will fully popularize digitalization and networking, and key enterprises in key industries will basically achieve intelligence.

At the same time, after the wind power industry has entered the era of grid parity, market competition has intensified, and the industry is under great cost pressure, and it is urgent to further tap the potential of all links in the industrial chain to reduce costs and increase efficiency."Digitalization and intelligence have become the primary productive forces of enterprises. Through continuous exploration and efforts, we have successfully built the first 5G fully connected smart factory in the wind power industry, and has been selected as a national 'Intelligent Manufacturing Benchmarking Enterprise', which is a new business card of Sany Renewable Energy and a key step for Sany Renewable Energy to become a leader in intelligent manufacturing. Peng Xu, chief digital officer of Sany Renewable Energy, told Wind Energy.

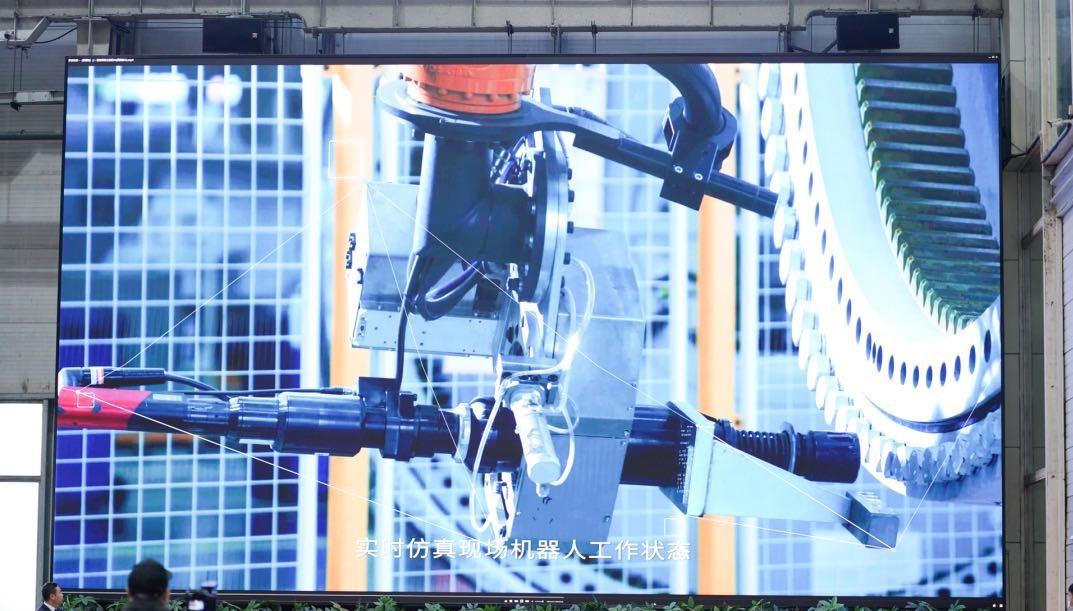

When the reporter visited the assembly workshop of Sany Renewable Energy Nankou Industrial Park, located in Changping District, Beijing, he saw that most of the work of the whole machine assembly has been automated, the real-time monitoring information of various parts and components on the production line is displayed on the electronic screen, and the mechanical arm is accurately and efficiently installed under the control of the operating system, and the AGV replaces the "overhead crane" to complete the assembly line distribution.

Peng Xu told "Wind Energy" that after several years of improvement, Sany Renewable Energy has formed a complete set of solutions in the automation of the whole machine production line, the integration of equipment, and the intelligence of production.

In terms of production line automation, Sany Renewable Energy has created a "pulsating" production system with flexible production capacity through the integration of robot application and lean production system. Intelligent robots replace manual labor in key processes to improve production efficiency and assembly quality reliability. In key processes such as pitch, yaw, transmission chain, cable, and material distribution, the six-axis robot, vision system, optoelectronic system, hydraulic, pneumatic, servo control, automation control, AGV, network interconnection, etc., are combined to form an unmanned production unit.

In terms of the Internet of Things, Sany Renewable Energy comprehensively monitors on-site production 6S, personnel safety and attendance, material use and storage through camera visual recognition technology, and uploads it to the Sanxian (on-site, real, and real) platform for intelligent analysis. Through the installation of smart water meters, electricity meters, gas meters and the application of IoT technology, intelligent analysis of real-time collection of water, electricity and gas consumption information, combined with the analysis of abnormal or peak energy consumption to reduce enterprise energy consumption; The Internet of Things technology is used to collect the data of workshop equipment, and at the same time establish a real-time database and historical database, and collect workshop production, quality and equipment information in real time through the integrated application of data acquisition system and digital information platform, so as to achieve accurate and rapid analysis, decision-making and response, and build a green manufacturing system.

In terms of production intelligence, through the construction of intelligent manufacturing information system, relying on the application and in-depth cooperation of PLM, ERP, MOM, WMS, QIS and other information systems, the factory data is integrated and opened, so as to achieve more efficient information transmission, production management and collaboration; Ensure that the workshop plan is accurately issued to the workers, and monitor the actual processing progress in real time, which changes the traditional way of working that relies on manual statistics, and solves the problem that the plan of traditional manufacturing enterprises is prone to disconnect with actual production.The value that results from this is obvious. According to the data provided by Sany Renewable Energy, after the above scheme was put into use, while the number of workers in the workshop was greatly reduced, the production efficiency was also increased by nearly 50%, and the product failure rate was reduced by 50%.

Peng Xu believes that the most significant change brought about by the promotion of intelligent manufacturing is the innovation of manufacturing mode and management system. For example, through the application of automation and intelligent software and hardware, the controllability of the core process is realized, and then the material distribution mode is changed from the traditional inventory type to the order type, that is, the material distribution is carried out based on the set of unit orders. For another example, real-time monitoring data makes the whole manufacturing process visible and transparent, which can not only effectively prevent product quality risks, but also make product quality traceable.

Although the construction of Sany Renewable Energy's smart factory has achieved initial results, in Peng Xu's view, there is still a long way to go. "What we are doing now is version 1.0, and we will work towards a higher level of intelligence in the future."

He admitted that it is very difficult for the wind power industry to promote intelligent manufacturing, not only with a wide variety of parts and components, but also with fast model iteration speed, and the unit manufacturing presents the characteristics of "multiple varieties and small batches". This requires flexible production, i.e. the same production line can produce multiple models. "Correspondingly, the supporting digital and intelligent equipment should also have a certain degree of versatility."

Another difficulty is the blades. Subject to the characteristics of the process, the production of blades has basically relied entirely on manual methods for a long time, and it is very difficult to promote intelligent manufacturing.

In addition, breakthroughs are also needed in the application of new technologies such as big data and artificial intelligence to control production quality, such as vision-based quality inspection.Taking blades as an example, Sany Renewable Energy is building a "Wind Power Blade Intelligent Manufacturing Super Factory" in Shaoshan, Hunan Province in accordance with Sany's "Lighthouse Factory" intelligent manufacturing standard, which is scheduled to be completed in May 2022. After the project is fully completed, the maximum annual production capacity will reach 1,000 sets of blades, with an annual output value of about 2 billion yuan and about 1,000 direct jobs.

Obviously, these are the directions that wind power companies need to continue to work on. In this regard, Sany Renewable Energy has been actively exploring.

Entering the "14th Five-Year Plan", Sany Renewable Energy will focus on continuously improving the level of digitalization and intelligence from five aspects, including the "four modernizations" of processes (standardization, online, automation, and intelligence), product electrification and intelligence, the construction of "lighthouse factory", and the deepening of software application and data application."Today, Sany Renewable Energy is facing the 'historic opportunity' and 'super technology window' brought about by the fourth industrial revolution and the third energy revolution." Peng Xu emphasized, "We will make unremitting efforts to build a digital ecosystem for wind power, and have planned a number of mobile factories across the country. It is hoped that by building green factories and smart factories, on the one hand, Sany Renewable Energy will be promoted to complete the transformation from traditional manufacturing to 'digital manufacturing and service-oriented manufacturing', and on the other hand, it will make first-class contributions in the field of new energy for the implementation of the country's '30·60 dual carbon' goal." ”

The convergence of the two forces also gives the future of the wind power industry unlimited imagination.

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationRelated testimonials

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

China's installed wind and solar capacity has historically surpassed that of thermal power

2025.04.28

0 comments