People's Daily Online: The assembly rate is as high as 64%! The country's first prefabricated project of "full prefabrication of walls, columns, beams and slabs, and full assembly of ground and underground" was completed

2022.08.11

Trinity Construction

On August 10, the capping ceremony of the country's first SPCS demonstration project of "fully prefabricated walls, columns, beams and slabs, and fully assembled above ground and underground" was held in Sany Industrial City, Changsha Economic and Technological Development Zone, marking the adoption with the completion of the pouring of the last concreteTrinity ConstructionThe "Yungu Jiayuan Building 3" of the SPCS structural system officially announced the capping of the main body.

It is understood that the Yungu project is located in the Economic and Technological Development Zone of Changsha City, Hunan Province, south of Liangtang Road and west of Dongsi Road, and is constructed by China Construction Second Bureau. Building 3 of the first phase is a SPCS demonstration building, which applies SPCS3.0 technology system, with a total construction area of 11,566 square meters, a building height of 74.8m, a total of 24 floors, a standard floor height of 2.95 m, and an assembly rate of 64.4%. The underground structure uses prefabricated cavity columns and cavity walls.

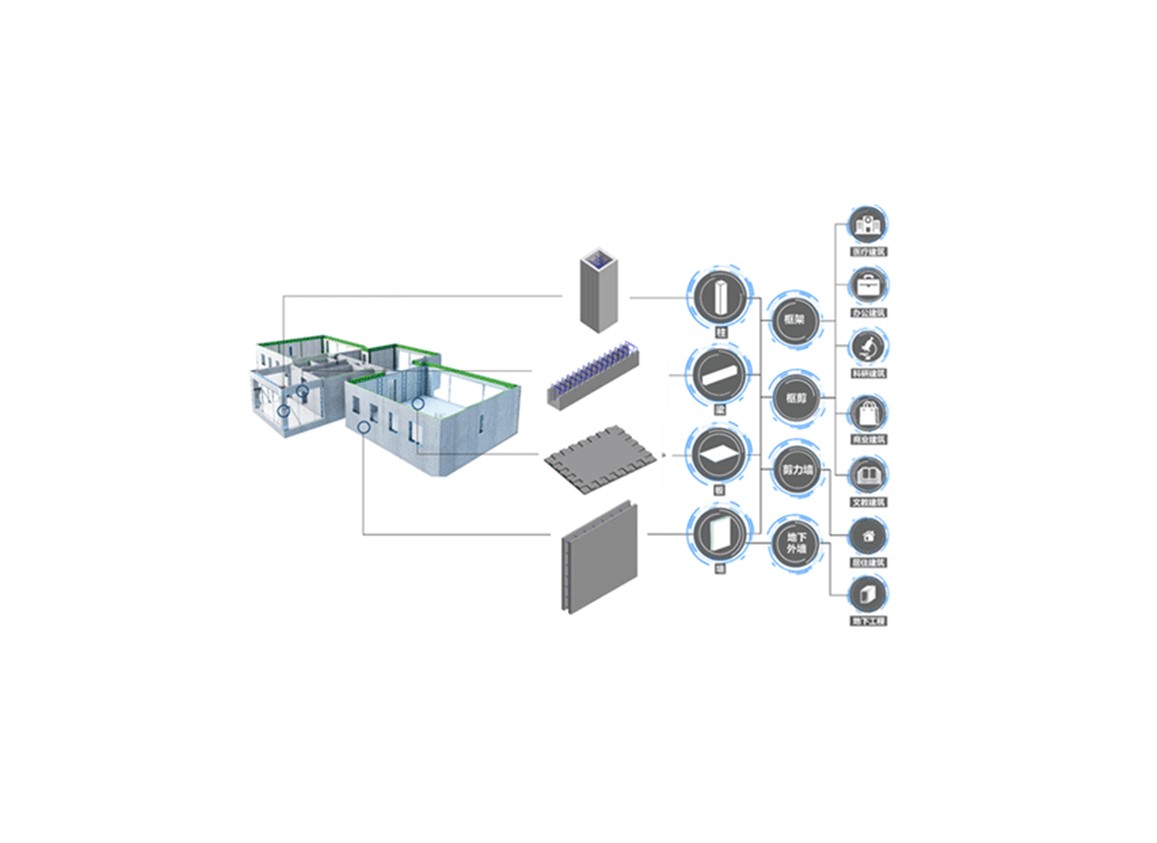

SPCS 3.0, the core technology of "cavity + lap + cast-in-place" developed by Sany Construction Engineering Co., Ltd., can realize the full assembly of the main structure, and the full prefabrication of aboveground and underground, walls, columns, beams and slabs. Its core technology solves the two major pain points of "overall safety questioning" and "high cost" in the field of prefabricated buildings from three aspects.

The factory prefabricates cavity components containing steel cages, which replaces the work of tying steel bars and supporting formwork on site; The forming connecting steel cage is placed in the cavity, and the connection between prefabricated components is realized through lap joint; Concrete is poured in the cavity to form a superimposed stressed body to ensure overall safety. "Cavity + lap + cast-in-place" is a process of "industrial cast-in-place", which not only retains the traditional cast-in-place practice, overall safety, good waterproof performance, high quality, but also uses the way of industrial production to improve production efficiency and reduce construction costs.

The SPCS cavity wall is a cavity prefabricated component composed of a formed steel cage and prefabricated wall panels on both sides. After the on-site installation is in place, concrete is poured in the cavity, and the cast-in-place concrete and prefabricated components form a whole by connecting the steel bars.

The reinforcement cage of the SPCS cavity wall adopts the structure of mechanical welded steel mesh sheets, which can realize large-scale industrialization, and adopts the double-mold table production process, and both sides of it are produced and formed on the mold table with high surface accuracy; The production efficiency is high, the outer surface of the component is smooth, smooth and plaster-free, the component is light in weight, the plate is large, the joints are less, and the construction is fast.

The SPCS basement cavity wall column of this project has a formed steel cage inserted into the cavity between the wall panels, and concrete is poured to form a whole. The basement using SPCS structural technology reduces the processes of earthwork excavation, wall reinforcement binding, formwork support, etc., greatly shortens the basement construction period, and is conducive to the progress of the engineering construction project.

Quadruple waterproofing is used between the cavity walls: exterior wall waterproofing membrane + exterior wall gluing + waterproof concrete + buried waterproof steel plate to ensure the waterproof performance of the basement exterior wall and solve the quality problem of traditional basement exterior wall leakage.

Yungu Jiayuan Building 3 adopts SPCS structural system, and adopts highly industrialized and intelligent production equipment compared with the traditional grouting sleeve prefabricated building, which accurately controls the whole process of component production and makes the component quality good; The component is integrally formed, with high precision, and can achieve the effect of no plastering; Eliminating grouting avoids the problem of temperature influence in the grouting process, and can realize normal construction in winter.

At the same time, the project adopts intelligent production equipment, and the production efficiency of components is higher; It can realize the rapid positioning and installation of components, effectively improve the utilization rate of tower cranes, and save construction periods; The reinforcement lap joint method equivalent to the cast-in-place structure is adopted, and the components are not reinforced, saving the cost of reinforcement materials; The amount of concrete prefabrication of components of the same volume is small, and the unit price of cavity components is 400-600 yuan/m³ lower than that of traditional prefabricated components.

SPCS structural system

Structural standardsRecommended products

Related testimonials

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

Hunan Satellite TV interviewed Sany Construction on the 2025 National Two Sessions

2025.03.11

Sany Construction Engineering is honored to participate in the recording of Hunan Satellite TV's documentary "Stars on the Top".

2024.12.23

0 comments