Let technological innovation become the engine of high-quality development of prefabricated buildings - the demonstration meeting of the application status and optimization plan of Sany prefabricated building structure technology

2022.10.19

China Construction News

"The SPCS structure system is safe and reliable, and has a wide range of application prospects. Recently, more than 30 experts from construction research institutes, associations and enterprises gathered at Sany Construction Technology Co., Ltd. (hereinafter referred to as "Sany Construction") to demonstrate the application status and optimization plan of Sany prefabricated building structure technology, and spoke highly of it.

SPCS structural system is a concrete prefabricated building system solution independently developed by Sany Construction Engineering. Over the years, the system has been guided by market demand, benchmarked against the development direction of cutting-edge technology in the industry, and continued to iterate, which has received extensive attention from inside and outside the industry. This demonstration meeting is not only a summary of the practical results of the SPCS structure system for many years, but also lays a solid foundation for the further expansion and promotion of the system in the future.

Adhere to technological innovation and lead the development direction

"The SPCS structural system originated from Europe, and is based on the prefabricated double-sided superimposed shear wall (double skin wall) system and the national standard superimposed shear wall system, after a large number of theoretical research and experimental verification, the superimposed shear wall technology formed after improvement and upgrading." Ma Rongquan, strategic consultant of Sany Group and director of the Rock and Soil Foundation Center of the State Key Laboratory of Deep Geomechanics and Underground Engineering, said, "Its convenient construction, reliable quality, good integrity and low cost solve the pain points of traditional prefabricated buildings, which is more suitable for China's national conditions and is recognized by the market." ”

According to the analysis of the expert group, the trend of "digitalization, industrialization and greening" in the construction industry continues to strengthen, and prefabricated buildings are developing in three directions: first, new prefabricated building technologies continue to emerge, and the degree of building industrialization continues to improve; Second, the prefabricated building structure system continues to innovate and develop, innovate and break through the core technologies related to intelligent construction, and form an integrated technology system covering the integration of the whole industrial chain such as design, production, construction and assembly, and operation, which has become the focus of industry enterprises; The third is the development of prefabricated buildings from structure-based prefabrication to full-professional prefabrication.

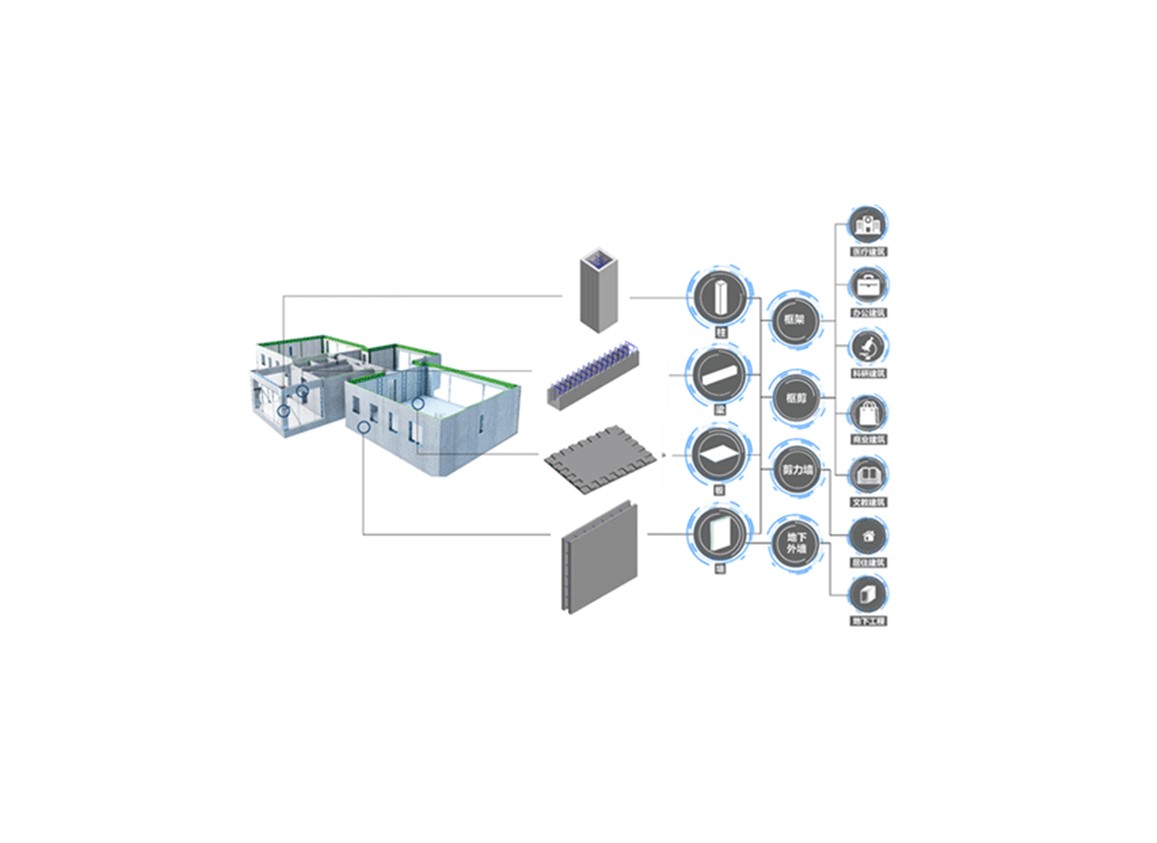

The SPCS structural system is recognized by the market because it is in line with the development direction of prefabricated buildings. At the beginning of research and development, the SPCS structural system has the characteristics of integrated technology: it is composed of "design, manufacturing, and construction, three hard intelligence, and Zhuxiang cloud platform", and has "5231" hard technology (5 types of equipment,Category 2 standards, 3 types of software, 1 project collaborative management cloud platform), with vertical structure prefabrication technology as the core, widely applicable to a variety of building products, compatible and effective bearing prefabricated enclosure, prefabricated decoration, green building and other aspects of construction technology, fully open up the "project pre-planning platform, E/P/C (design/production/construction) real-time online collaboration, BIM (Building Information Model) twin delivery" scenario, will be "investment and planning, planning and design, production and procurement, construction and delivery, operation and consumption" The intelligent application scenarios of the whole life cycle lead to reality.

Currently, the SPCS architecture has been upgraded from version 1.0 to version 3.0. The expert group fully affirmed the attitude of the SPCS structural system to continuously iteratively develop by solving the practical problems of project application.

The system is safe and reliable, and the application prospect is wide

At the demonstration meeting, Ma Yunfei, chief engineer of Sany Construction Engineering, introduced the development process of SPCS structural system and the national application status, and made an in-depth analysis and sharing of the problems of superimposed shear wall "expansion mold", post-cast concrete quality control and impact that the industry is concerned about. Li Ran, a researcher at China Academy of Building Research, introduced the theoretical analysis and experimental research of SPCS structural system since 2018 with the title of "Research on Assembled Integral Steel Welded Mesh Superimposed Concrete Structure (SPCS)".

The SPCS structural system simplifies the construction process into "cavity wall column + mold whole plate + mold node + lap post-pouring + in-plane operation", which has the overall advantages of "cavity lap plus post-pouring, equivalent heterogeneity is good and fast and saving", and truly realizes systematic design, factory manufacturing and industrial construction. In terms of design, Sany Construction Engineering Co., Ltd. cooperated with Beijing Structural Technology Co., Ltd. to develop PKPM+ SPCS prefabricated intelligent deepening design software, which innovatively broke through the development bottleneck in the field of intelligent construction design, and solved the problems of low design efficiency, poor design quality and difficult data application. In terms of component production, the whole process of component design, production and delivery has been opened, and the self-developed software and hardware integrated digital factory solution, including intelligent equipment and control system, can automatically complete production actions such as marking, formwork, steel bar processing and delivery, pouring, maintenance, and quality inspection according to the flow beat, compared with traditional PC factories, the number of workers has been reduced by 40%, the time taken has been shortened by 40%, and the production capacity has been increased by 100%; In terms of component transportation and hoisting, compared with the traditional combination of solid prefabricated walls and columns, the main stressed components such as cavity walls and columns are lighter, which is convenient for transportation and faster hoisting; In terms of on-site construction management, the component connection adopts indirect lap joint or mechanical connection of steel bars, and there is no grouting sleeve, which can effectively avoid the quality hidden dangers that may be generated by the conventional connection mode, ensure the construction quality, reduce the construction cost of the prefabricated building by reducing the amount of on-site formwork and steel reinforcement engineering, and reduce the outdoor operation by using the industrial construction method, and improve the construction safety.

Combined with the project under construction in Changping District, Beijing, Ma Zhen, head of the supervision team of the Quality and Safety Supervision Station of the Housing and Urban-Rural Development Commission of Changping District, said that the SPCS structural system has the advantages of simple component installation and operation, fast speed and high efficiency. Compared with different prefabricated projects in the same region, the construction speed of the main structure of the project using the SPCS structural system is significantly faster than that of other projects, and the capping can be achieved faster.

By listening to the application report, consulting the technical data, after questioning and discussion, the expert group reached a consensus:

First, the SPCS structural system has undergone a lot of theoretical analysis, experimental research and engineering practice, and is safe and reliable under the design, production and construction conditions that meet the current standards, and has a wide range of application prospects. The "Technical Regulations for Assembling Integral Steel Welded Mesh Stacked Concrete Structures" and "Technical Regulations for Assembling Integral Concrete Structures for Underground Engineering Waterproofing" provide strong support for the application of the system.

Second, the superimposed shear wall anti-expansion mold and post-cast concrete compactness guarantee measures proposed by the technical research and development team are reasonable and feasible. In the case of dense and full cavity concrete pouring, the structural safety performance can meet the requirements of the specification.

This opinion is an endorsement of the security of the SPCS structural system. The technical system and related technical standards have a promoting and leading role in the development of prefabricated buildings, and the SPCS structural system has wide promotion and application value. In addition, the opinions responded to some questions about the double-sided superimposed shear wall system in the industry, and based on the continuous "R&D-practice-improvement" cycle, SPCS has been able to effectively solve the common technical problems of the double-sided superimposed shear wall system and ensure the structural quality.

Improve the structural system and give full play to greater potential

Fan Chong, the leader of the expert group, the chief engineer of China Architectural Design and Research Institute, and the national survey and design master, said that the development of each technical system must go through the process of theoretical design, test verification, introduction of standards, to project practice, and then to technical improvement and iteration, and gradually mature. The innovation and development of each technical system is the surging engine that promotes the sustainable development of prefabricated buildings. From a practical point of view, the SPCS structural system has a good effect on the application and has great potential for development in the future.

Ma Rongquan said that the overall safety and reliability of the SPCS structure system are beyond doubt. In the future, Sany Construction Engineering should insist on innovation and set an example in solving the common problems of the industry such as "mold expansion" and "low concrete pouring quality".

Li Hongqiu, CEO of Beijing Weituo Times Architectural Design Co., Ltd., believes that in the development of SPCS structural system, we should not only pay attention to the preparation of design standards, but also summarize experience in the construction stage, form process construction methods, formulate standardized production and quality control processes, and minimize the dependence on the ability of on-site construction personnel.

Tian Chunyu, Secretary-General of the Precast Concrete Component Branch of China Concrete and Cement Products Association, said that prefabricated buildings have experienced a process from large-scale development to connotative development in recent years, and more and more enterprises with strong technology and advanced management have come to the fore. Sany Construction Engineering should pay attention to technology accumulation, maintain sensitivity to advanced technology, and continuously improve the quality control ability of component production.

Tian Dong, deputy director and deputy chief engineer of the Construction Industrialization Engineering Technology Research Center of Beijing Architectural Design and Research Institute, believes that the study of low-cost quality testing methods is a necessary way to ensure the quality of post-cast concrete and ensure the mechanical performance of the structure.

In view of the development status and industry needs of the SPCS structural system, and the summary of expert opinions, the expert group put forward three suggestions: first, compile a unified technical manual for the production of SPCS structural components and strengthen the control of the production process of components; the second is to formulate unified technical measures for the construction of SPCS structural system and strengthen the technical guidance of the whole process of construction; The third is to further study the optimization of the reinforcement form of the edge members of the shear wall, promote the continuous improvement of the SPCS structural system, and make new and greater contributions to the high-quality development of the prefabricated building industry.

It is understood that at present, the SPCS structure system has been promoted and applied in Beijing, Shanghai, Tianjin, Chongqing, Hunan, Shandong, Guangdong, Zhejiang, Jiangsu and Shaanxi and other provinces and cities, with a cumulative application area of nearly 10 million square meters. With the continuous iteration of this technology system, its application scope will be further expanded.

SPCS structural system

Structural standardsRecommended products

Related testimonials

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

"Science and Technology Daily" Focus! Sany 6 minutes "intelligently made" an electric heavy truck

2025.04.25

Hunan Satellite TV interviewed Sany Construction on the 2025 National Two Sessions

2025.03.11

0 comments