CCTV broadcasts two in a row, focusing on Sany!

2024.08.19

CCTV News

On August 18, the CCTV news channel "China's New Discoveries" series of reports focused on the "Lighthouse Factory", focusing on Sany from the new technologies and applications in intelligent manufacturing, and discovering the new driving force and new growth of China's economy.

Known as the "world's most advanced factory", the "Lighthouse Factory" is selected and recognized by the World Economic Forum, representing the world's highest level of intelligent manufacturing, and the comprehensive automation, precision and optimization of the production process guide the new direction of digital transformation of the global manufacturing industry.

China is the country with the most "lighthouse factories" in the world, and 62 Chinese factories have been announced in 11 batches of 153 "lighthouse factories" in the world. Since the beginning of this year, the growth of high-tech manufacturing represented by the "lighthouse factory" has accelerated. The latest data show that in July, the added value of China's high-tech manufacturing industry increased by 10.0%, 1.2 percentage points faster than the previous month.

So what exactly does a "lighthouse factory" look like? What's new this year? What role does it play in China's economy?

AI system simulation learning budget-conscious "tailor"

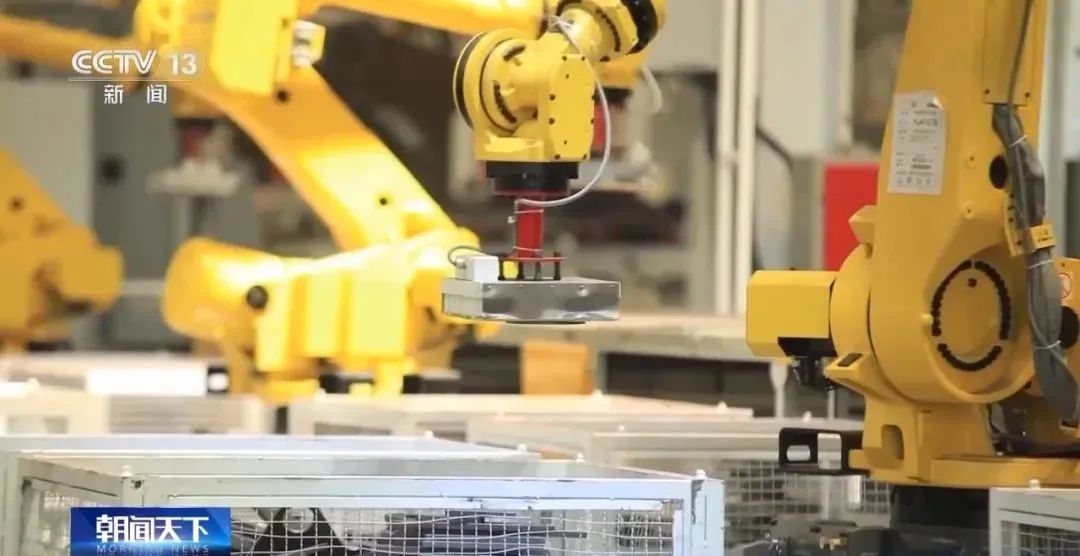

In the evaluation criteria of "lighthouse factory", the use of automation, digitalization, 5G communication and other technologies to reduce costs and increase efficiency for enterprises and industrial chains is an important indicator. In the investigation, the reporter found that behind each "lighthouse factory", there is a "smart brain" that directs the robots and workers on the production line to work together, so that each production link can use the least materials and do the fastest work.

A "lighthouse factory" in Changsha, Hunan Province, mainly produces pump trucks for construction machinery. The person in charge of the factory told reporters that a pump truck can be assembled and rolled off the assembly line in 45 minutes at the earliest.

The production of a pump truck starts from cutting spare parts, cutting a steel plate in a few steps, and the answer is that it can be done with one button.

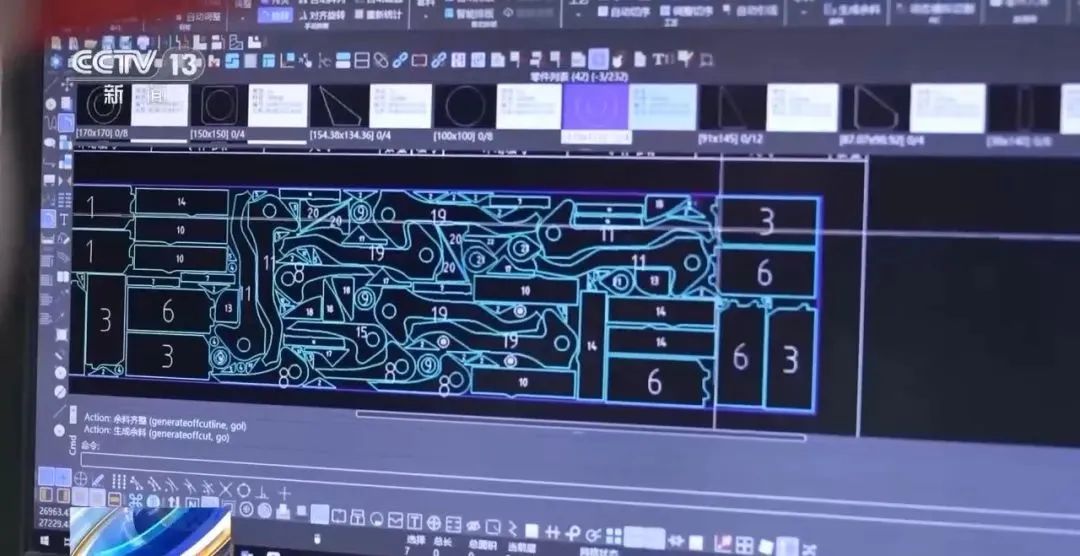

Guo Pengxiang, Blanking Molding Engineer of Sany Heavy Industry Intelligent Manufacturing Headquarters: As long as we get the nesting order, click an intelligent typesetting on the screen, and the entire intelligent "brain" will generate a nesting diagram according to the optimal utilization rate, and the robot can cut.

How to make the best use of the material, has always been a headache for enterprises, relying on manual drawing on the steel plate to draw the shape of the spare parts and then cutting, low efficiency, more waste.

Guo Pengxiang, Blanking Molding Engineer of Sany Heavy Industry Intelligent Manufacturing Headquarters: Around 2019, the average utilization rate of steel in the whole group was only about 70.8%, and even experienced programmers could not achieve the optimal utilization rate of nesting diagrams. We saved the best nesting results in history and started letting the AI learn automatically.

The AI system not only increases the number of spare parts on each steel plate, but also matches the spare parts of other construction machinery and equipment through data, and guides upstream enterprises to provide more accurate raw materials to reduce waste.

Guo Pengxiang, Blanking Molding Engineer of Sany Heavy Industry Intelligent Manufacturing Headquarters: Originally, I only produced spare parts for pump trucks here, and now I can also produce fire trucks.Tow pumpFor each point that the utilization rate of steel plates is improved, the procurement cost can save 20 million yuan per year.

After the AI system was launched, the company's steel utilization rate increased by 11 percentage points.

Guo Pengxiang told reporters that in addition to the nesting link, the welding robot in the factory can control the weld at the millimeter level, and weld the turntable of the pump truck with 1/6 of the time, and the blanking robot and AGV trolley can send the spare parts of each link to the station at a speed accurate to the second, and the robot can dynamically control the baking power according to the current room temperature in the baking room to reduce energy consumption.

In the process of continuous learning, the smart brain gradually exerts the highest efficiency and reduces the most cost of the factory, the automation rate of the factory is close to 80%, the production capacity is increased by 123%, the personnel efficiency is increased by 98%, and the unit manufacturing cost is reduced by 29%.

Yao Zhiheng, Director of Sany Heavy Industry Pump Intelligent Manufacturing Technology Institute: Our system is not only used to optimize the production process, but also to network all the equipment sold out, through which R&D, manufacturing, sales and after-sales can work together.

Flexible production line industrial export to participate in global competition

The construction machinery industry has the characteristics of strong cyclicality, many types of products and small batches, and enterprises must adjust the production plan at any time according to the market order demand to resolve market risks.

In the "lighthouse factory", the application of intelligence and digitalization makes flexible production possible. While reducing costs and increasing efficiency, it helps enterprises easily adjust production plans and expand their business to overseas markets.

In this "lighthouse factory", the reporter saw that the pump truck turntable that the robot was welding was not the product of his own company.

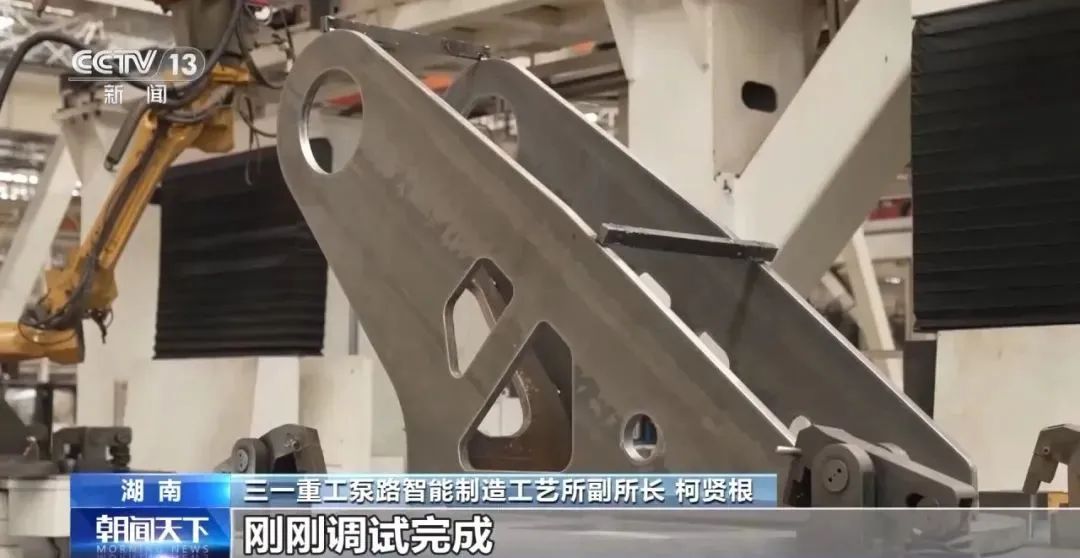

Ke Xiangen, Deputy Director of Sany Heavy Industry Pump Intelligent Manufacturing Technology Institute: This is the 47-meter turntable of Putzmeister that we produced, which has just been commissioned and will be able to be mass-produced next month.

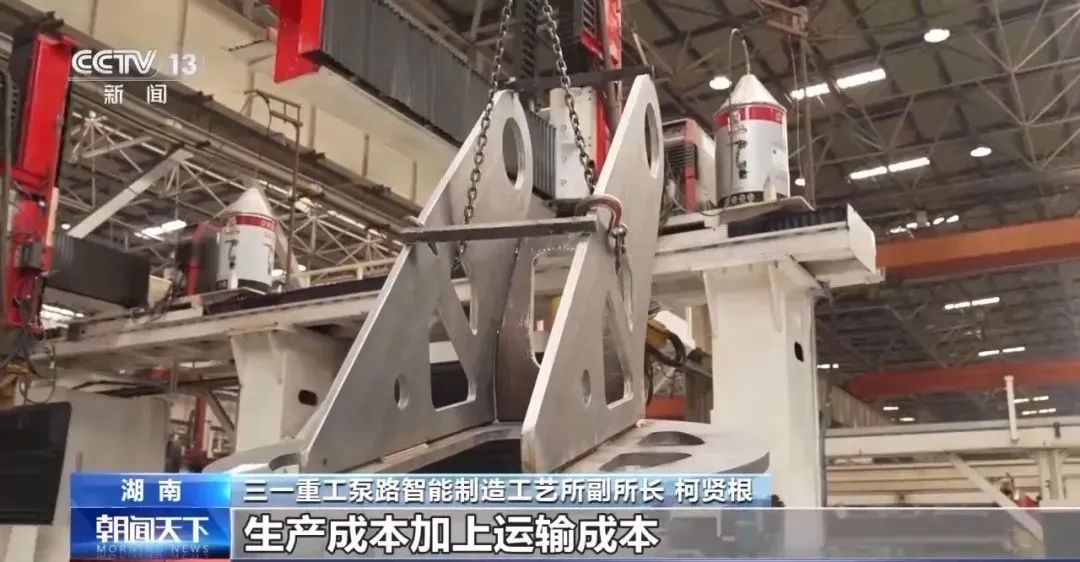

In 2012, Sany Heavy Industry acquired 100% of the shares of Putzmeister in Germany, and the two companies tied the knot and deepened cooperation in R&D and marketing, but the production lines of their respective products were not combined. Putzmeister's pumps are sold in the high-end European and American markets, with an assembly plant in Turkey, where parts have been ordered for product assembly.

Ke Xiangen, deputy director of Sany Heavy Industry Pump Intelligent Manufacturing Technology Institute: The cost of their purchased parts is more than 2 times higher than that of our self-made, and the standard applied by Putzmeister is the European standard, which has high requirements for welding seams and refinement.

The high cost of raw materials and labor made Putzmeister look to its partners in the East. The flexible production line of the "lighthouse factory" can not only meet the company's own production, but also fully adapt to European standards with intelligent and automated technology.

Ke Xiangen, deputy director of Sany Heavy Industry Pump Technology Institute: Our turntable welding adopts arc tracking technology, the accuracy can reach the millimeter level, and the program can be switched at any time to produce different models. Production costs, plus transportation costs, are 20% lower than local production in Putzmeister.

The person in charge of the factory told reporters that not only the "lighthouse factory" can produce foreign equipment, but the company will also promote and copy the "lighthouse factory" model overseas. In Indonesia, China's construction machinery industry's first overseas "lighthouse factory" is operating steadily at an annual output of 3,000 excavators, 12 processes, more than 500 robots of the full network connection and unmanned production, completed the first overseas systematic output of intelligent manufacturing in China's construction machinery industry.

Yao Zhiheng, Director of Sany Heavy Industry Pump Intelligent Manufacturing Technology Institute: We are now talking about globalization from product exports to industrial exports, and through Chinese enterprises to lead the allocation of resources and better serve global customers. In the future, the "Lighthouse Factory" will not only be an independent factory, but will form a set of intelligent decision-making and highly flexible manufacturing system based on the "Lighthouse Factory", so as to help Chinese enterprises better participate in global competition.

Source: CCTV News

Recommended products

HBT12020C-5M

Trailer pump HBT12020C-5MRelated testimonials

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

Hunan Merchant Lecture Hall! To Wenbo!

2025.05.16

0 comments