Digital intelligence technology to improve the quality of building industrialization - China Construction News interviewed Ma Yunfei, director and chief engineer of Sany Construction Engineering

2024.12.17

China Construction News

(The full text of the following is reprinted from the December 17 "China Construction News", reporter Wang Haixia)

Empowering the high-quality development of cities with digital technology has become an important topic in the current construction industry. At the 2024 Seminar on High-quality Development of Chinese Cities, the reporter of this newspaper interviewed himTrinity ConstructionMa Yunfei, Director and Chief Engineer of Technology Co., Ltd. (hereinafter referred to as Sany Construction), based on the latest achievements of digitalization and industrialization, discussed the role of intelligent manufacturing in the transformation and development of the construction industry, and explored a new path for new technologies to help the high-quality development of the construction industry.

The level of construction industrialization still needs to be improved

What is Smart Construction? Intelligent construction is a new construction mode with modern information technology as the core and advanced construction technology led by industrialization. It is the focus of the current transformation and upgrading of building industrialization.

Ma Yunfei believes that there are two major pain points in traditional construction methods, one is that design, construction, procurement and other links are segmented, which requires the integration of modern information technology into the industry; Second, the cast-in-situ construction method of traditional concrete structure relies on a large number of on-site manual work, and there are many problems in the construction, such as scattered and dirty, poor labor, uncontrollable quality, and insufficient green environmental protection.

To this end, Sany Group has put forward the three concepts of "from construction to products, from construction to manufacturing, and from offline to online", and has opened up the five major stages of the construction industry with the platform technology of industrial Internet of Things + AI as the basic base, empowered intelligent construction with intelligent manufacturing, and helped accelerate the process of building industrialization.

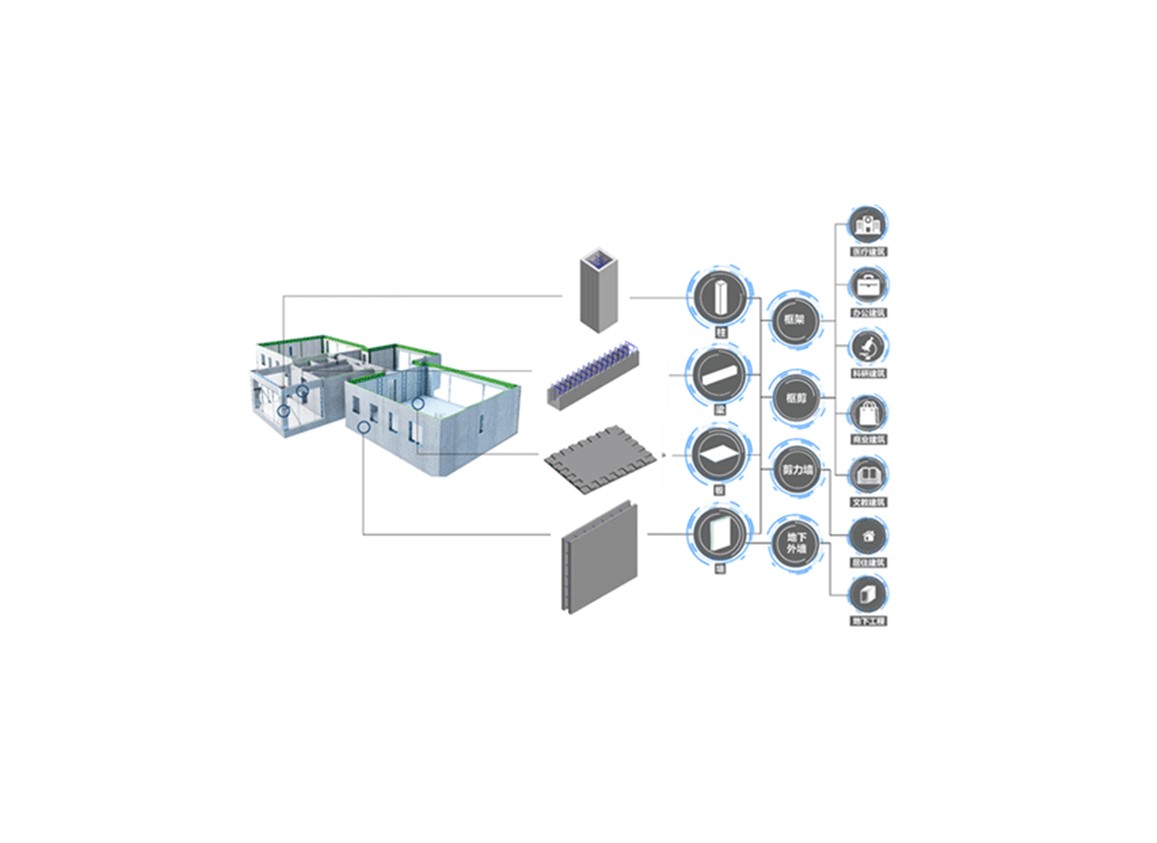

Specifically, "from building to product", that is, the industrialization of construction must start from the design side, and Sany Group's SPCS (equipment, technology, cloud platform) product technology is to carry out integrated and integrated product design from the DFMA concept, and consider factors such as production technology and construction technology to design building products suitable for industrial production. "From construction to manufacturing" is to turn the construction link into a combination of manufacturing and construction, that is, to complete the manufacturing of building parts and components in the factory through digitalization, informatization, mechanization and automation, giving full play to the advantages of intelligent equipment and realizing intelligent construction. "From offline to online" is to manage the traditional and offline building construction process through cloud leveling, and truly realize online collaboration and digital twin.

The industrialization of construction makes building a house like building a car

The Ministry of Housing and Urban-Rural Development's proposal to "build a house like a car" is to realize the industrialization of construction. As one of the world's "top three construction machinery enterprises", Sany Group has traditional advantages in the production of heavy trucks and automobiles, and has also made fruitful scientific and technological achievements in promoting the digital transformation of the construction industry.

In order to realize intelligent construction, Sany Construction Engineering has developed SPCS intelligent construction solutions from three aspects: equipment, technology and cloud platform. In terms of technology, it mainly focuses on the complex concrete main structure in traditional construction, and summarizes it as cavity, lap joint, and post-pouring with three key words. Through this system, the digital, mechanized and automated production of cavity components in the factory can be realized, and the industrialization of component production can be realized; Then the steel bar lap link and rapid assembly are carried out on the site to realize the industrialization of the site. In addition, moderate post-pouring in the cavity can maximize the characteristics of concrete structural materials.

The construction of this technical system can make building a house like building a car. Ma Yunfei introduced that the technical system saves 5-10% of the cost compared with the traditional prefabricated construction technology, and the construction speed can achieve a floor in 4 days, the structure is safer, and the building waterproof performance is better. For example, in the "First Batch of Replicable and Popularizable Demonstration Projects of the Intelligent Construction Engineering Technology Innovation Center of the Ministry of Housing and Urban-Rural Development" Xingsha Experimental School Affiliated to Hunan Normal University, after using the SPCS intelligent construction solution, the project construction period is reduced by 60 days compared with the traditional prefabricated technical solution, the cost is reduced by about 10%, and the project quality is greatly improved.

Sany Group has also developed a series of intelligent equipment for construction industrialization, such as PC, steel bar, AAC, and construction solid waste recycling equipment. Among them, in terms of PC equipment, more than 70% of the processing operations of traditional concrete components such as steel bars, formwork and concrete can be completed by mechanical automation, which can reduce labor by 40%, save water by 35%, save wood by 60%, and reduce energy consumption by 30%, which is a vivid interpretation of the development goal of new building industrialization with the integration of industrialization and greening.

The integration of digital and AI technology improves the quality of building industrialization

In the new stage of digital twin + AI integration and development, it is necessary to solve the pain points of traditional construction methods, promote digital management innovation in the whole life cycle of construction, and digitally transform to a wider dimension based on industrial construction technology.

Ma Yunfei believes that through the development of management platforms, design software, and management software, digital management is realized in the whole life cycle of construction, and online collaboration and digital twin of all cycles, roles, and elements in the entire construction process are the future development direction of architecture.

"The introduction of digital twin means that when building a physical building, a set of building information models that grow with the building are submitted simultaneously, and the model must be one code and information collaboration." Ma Yunfei believes that this is actually a higher requirement for the level of building industrialization, starting from the design stage of components, it is necessary to introduce intelligent design software to produce a one-yard architectural model. In the production stage, the intelligent equipment of the factory analyzes the model data, and the mechanized and automated processing of the prefabricated components is driven by data, in this process, the digital twin means that the construction status of the building is dynamically displayed in real time through the different colors of the building components, so that the construction progress can be seen at a glance.

Sany Group has also developed a special cloud platform for the construction industry, which realizes online collaboration, information sharing, data-driven, real-time feedback and dynamic coordination among all parties involved in the construction, thereby greatly improving the level of on-site management, reducing the construction change rate by 2/3, reducing on-site management personnel by 10%, and improving management efficiency by more than 10%, realizing the innovative practice of intelligent construction in construction management.

SPCS structural system

Structural standardsRecommended products

Related testimonials

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

Sany silicon energy "wins" Africa

2025.06.18

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

0 comments