CCTV Finance + People's Daily frequently focuses: Sany Renewable Energy goes to sea to accelerate sailing!

2025.03.26

CCTV Finance and Economics, People's Daily

In the context of the hot orders for wind power to "go to sea", what new requirements will be put forward for the production capacity of enterprises? How to deal with the next new export opportunities?

From March 23rd to 24th, CCTV Finance's "Tianxia Finance" column and "People's Daily" successively focused on Sany Renewable Energy to report the latest trends of enterprises in intelligent manufacturing of wind power equipment and speeding up going to sea.

Customized production

China's wind power exports are expected to grow further

In a wind turbine manufacturing workshop in Beijing, 16 automated production lines are running at full capacity in an orderly manner. The staff told reporters that in March this year, they had entered the peak production period, four months earlier than last year, and the production line was also upgraded to better meet the customized needs of export products.

Yang Bo, Deputy Director of Sany Renewable Energy Manufacturing Headquarters: In 2025, the production schedule of our entire overseas projects will triple compared to 2024. It can be compatible with flexible production from 3 MW to 15 MW models, and can now achieve the delivery speed of one (wind turbine) off the assembly line in three hours.

In addition, the exported wind turbines must meet the international standard of 25-year service life. In order to ensure the follow-up operation and maintenance of export wind turbines, from initial design to test and test, enterprises have established supporting measures for the whole chain.

Sany Renewable Energy Test Engineer Han Bo: For export blades, we have to carry out a fatigue test for 25 years (service standard). Generally (wavering) we are 1 million to 2 million (times), and then oscillating, we are generally 3 million to 4 million (times) to ensure a reliability of its (operation).

According to the Global Wind Energy Council, by 2025, the global installed capacity of offshore wind power will reach a new high, reaching 25GW. In the next five years, the world's new grid-connected wind power capacity will reach 680GW. Industry insiders said that overseas markets have become the main incremental markets for Chinese wind power companies.

Chen Sitong, power equipment and new energy analyst at China Securities Securities: The proportion of such high value-added offshore wind turbines exported by China in the future, as well as the proportion of high value-added parts, will be further increased. It is expected that in 2025, China's export volume of wind turbines and export orders will further increase, which is expected to open up more space to go to sea.

Break through the challenges of customization and high precision

New progress has been made in the intelligent production of high-end equipment

A gentle breeze, the standing wind turbines rotate leisurely, sending out a steady stream of green electricity. How is such a behemoth made?

Many people may not think that the production of blades, the key component of wind turbines, has long been a labor-intensive industry, and due to its large volume, heavy weight and complex surface surface, it often relies on a large number of manual processes such as laying, pouring, grinding and painting.

Nowadays, walking into Sany Renewable Energy's Shaoshan Blade Factory, the fully intelligent auxiliary positioning technology helps shape the main beam of the blade and form the "backbone" of the blade; Large-scale centralized perfusion technology realizes the automation of the whole process of resin material intake, storage and use, and builds the "muscle" of the blade; The robot cooperates with laser guidance technology to automatically complete the surface grinding and painting of the blade to improve the "skin" of the blade...... In just one day, an 82-meter-long blade can be rolled off the production line in the smart workshop.

"Such efficiency is due to the perfect combination of intelligent brain and intelligent equipment, which realizes automated production by improving the process flow." Peng Haibing, head of Sany Renewable Energy's Shaoshan Blade Factory, said that as long as a tablet computer, it can monitor the temperature and humidity of the workshop, the blade grinding smoothness coefficient and other indicators in real time, and realize the lean management of the whole process.

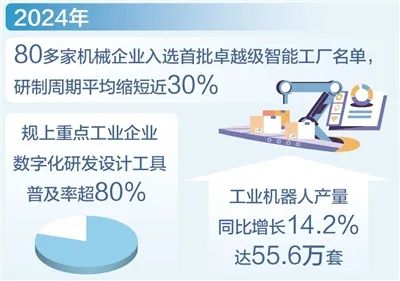

Data source: China Machinery Industry Federation Drawing: Wang Zheping

In recent years, new progress has been made in the intelligent production of high-end equipment in China. According to data from the China Machinery Industry Federation, more than 80 machinery companies will be selected into the list of the first batch of excellent smart factories in China in 2024, and the development cycle will be shortened by nearly 30% on average; The penetration rate of digital R&D and design tools in key industrial enterprises above the designated size exceeds 80%.

"This achievement is not easy to achieve." Liu Qianjun, Secretary-General of the Intelligent Manufacturing Branch of the China Machinery Industry Federation, introduced that the production and manufacturing of high-end equipment is a typical discrete manufacturing, with many product categories and complex structures, which puts forward higher requirements for intelligent transformation.

One of the challenges lies in the contradiction between customized needs and standardized production.

High-end equipment is mainly concentrated in aerospace, rail transit, construction machinery and other fields, these products are often highly customized, and each product may have different specifications.

"Enterprises often use collaborative robots, automatic guided vehicles, etc. to achieve dynamic adjustment of production lines, but it is still difficult to break through the flexible production of large items." Liu Qianjun said.

The second challenge lies in the process requirements of high-precision and high reliability of high-end equipment.

The processing accuracy of many high-end equipment is micron-level, and it is difficult for traditional automation equipment to meet the requirements. Complex process parameters also put forward extremely high requirements for intelligent transformation.

Data show that in 2024, the output of industrial robots in China will increase by 14.2% year-on-year to 556,000 sets, a new high. Many enterprise leaders expect that with the rapid development of intelligent manufacturing equipment, the intelligent transformation of high-end equipment factories can continue to make breakthroughs.

"The development of intelligent manufacturing equipment is conducive to the realization of the goals of efficient and flexible, agile response, human-machine collaboration and dynamic scheduling of high-end equipment intelligent factories." Liu Qianjun suggested that it is necessary to give better play to the leading role of state-owned central enterprises and leading enterprises in the industry, encourage them to explore the intelligent transformation of key processes, and provide reference for the intelligent transformation and upgrading of the industry. At the same time, strengthen financial support, and encourage the use of multiple financing models to promote the construction of smart factories through the formulation of differentiated credit policies and innovative financial products.

Content source: CCTV Finance, People's Daily

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationRelated testimonials

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

CCTV factory visit! Sales surged in the first quarter, and Sany Heavy Machinery was at full capacity

2025.04.09

CCTV "Focus Interview" focus! Sany helps the "double carbon" process!

2025.04.04

0 comments