The 4,500-kilometer Sichuan-Tibet Railway special inspection, the more difficult and dangerous, the more forward!

2022.06.12

Sany Heavy Machinery

In order to better serve customers, ensure the construction progress of the Sichuan-Tibet Railway with high quality, and practice the concept of quality changing the world and service creating value, since May 24, the Sichuan-Chongqing Branch has carried out special inspection work on the construction equipment of the Sichuan-Tibet Railway Sany to gain an in-depth understanding of customer needs, solve the problem of spare parts supply, and improve the service efficiency of the plateau.

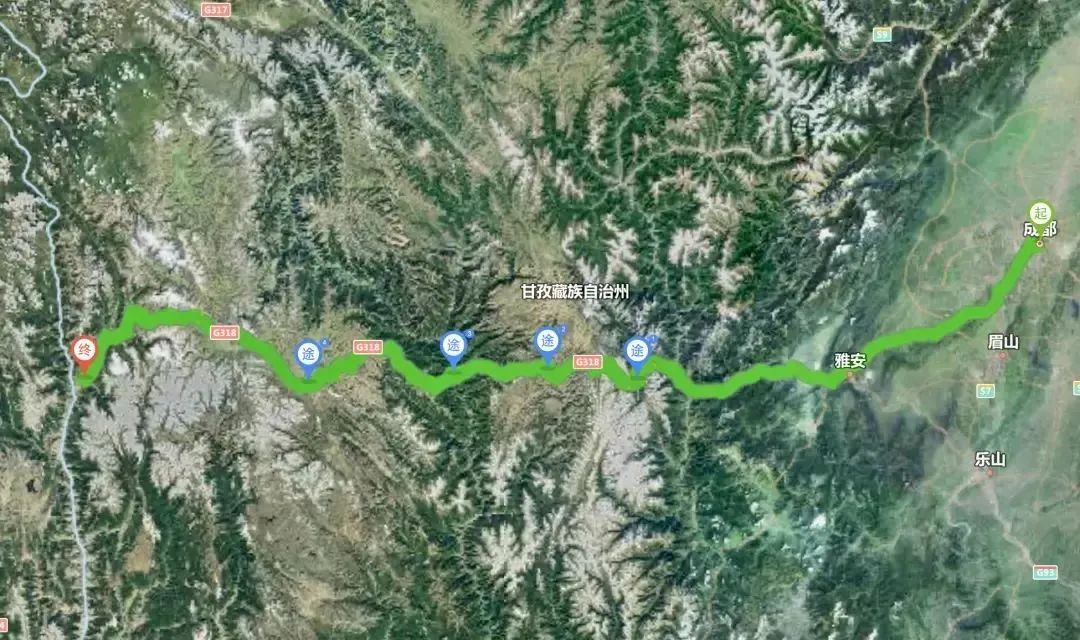

Patrol routes

Chengdu - Yajiang - Litang - Batang - Qamdo - Tongmai - Lulang

The Sichuan-Tibet Railway has a total of 25 Sany pile driver equipment, and has completed the special inspection of all equipment.

First stop Yajiang

Starting from Chengdu via Kangding and Xinduqiao to Yajiang to start a special inspection, this inspection helped customers clean the cab and air conditioning filter to ensure the comfort of the driver, including cleaning the air filter, ensuring that the air intake of the equipment is normal, changing the engine oil, cleaning the power head iron filings, etc.

The second stop is Litang

On May 26, the special inspection team arrived at the second station, Litang, due to the altitude of more than 4,000 meters, the high anti-anti is a major obstacle to the work. The inspection team needs oxygen for every service, but the engineers have been consistent in their service quality, carefully testing the oil grade, cleaning the air intake filter, heat sink, etc.

Stop 3 Batang

The third stop arrived at Batang, the special inspection team came to the construction site to help customers replace accessories, conduct special inspections, and senior engineers explained the precautions for the use of drill pipes, which won unanimous praise from customers.

Fourth stop: Qamdo, Tibet

After finishing the work in Batang at 4 o'clock in the afternoon, the special inspection team immediately drove for nine hours to Qamdo, Tibet, and the road was bumpy, not only needing to pass through rugged mountain roads and accident-prone sections such as mud and rockfalls, but also climbing over an altitude of 4,600 meters, the difficulty can be imagined. Even so, the inspection work is still in full swing and in an orderly manner.

The fifth stop: Tongmai, Tibet

In the complex environment of the plateau and mountainous areas, the engineers overcame low temperature and altitude sickness, arrived at the customer's construction site and immediately started special inspections, deeply understood customer needs, carefully solved customer problems, and practiced exceeding customer expectations and industry standards with practical actions.

The sixth stop: Lulang, Tibet

After arriving in Lulang, the construction engineer trained how to use the machine lock lever correctly on the spot, and inspected 5 local equipment, which was highly appreciated by the customer.

On May 31, the Sichuan-Tibet Railway Special Inspection Team of Sany Pile Driver Sichuan-Chongqing Branch completed the special inspection of a total of 25 Sany Pile Driver Equipment on the Sichuan-Tibet Railway, with a total of 4,500 kilometers.

Plateaus, hypoxia, rockfalls and other emergencies cannot stop the pace of Sany Service. The special inspection team comprehensively inspected the use of the equipment, further eliminated the hidden dangers of the equipment, and provided a strong guarantee for the Sichuan-Tibet Railway Project.

Next article:No.1 in the industry! Sany won 8 awards!

Related testimonials

Digital intelligence service is upgraded again, how does Sany build a win-win after-sales ecosystem?

2025.04.23

CCTV factory visit! Sales surged in the first quarter, and Sany Heavy Machinery was at full capacity

2025.04.09

In February, the domestic sales of excavators doubled year-on-year, and the construction machinery industry is now a strong recovery signal

2025.03.18

0 comments