Highly recommended! Sany large width 20 meter paver SAP200C-10!

2024.12.30

Product positioning

SAP200C-10 paver is a construction artifact created for high-speed 2-lane 4-lane asphalt wide construction. As a new generation product, it greatly improves construction efficiency and significantly reduces joints with the four core performances of high flatness, no segregation, strong power and economical operation, thus effectively improving the flatness and durability of the pavement and ensuring a significant improvement in pavement quality.

Construction case

In the Hubei Xiaogan Beijing-Hong Kong-Macao reconstruction and expansion project, the paver achieved one-time paving with a paving width of 19.25 meters in actual construction, which is the first time in the field of domestic and even international road construction.

In the construction of Guangxi Guanping Expressway, the SAP200C-10 paver showed its excellent performance, making the flatness of the upper and middle surface layers reach a high precision σ range of 0.327-0.375 and 0.504-0.535 respectivelyConstruction standardsIt greatly ensures the smoothness and safety of road driving, providing drivers with a more comfortable and safe driving experience.

The upper layer of the 2 lanes of Ningxia Yinkun Expressway G85 (Sun Mountain Development Zone-Pengyang Section) is constructed, with a cumulative construction length of 62km and a mean square difference of flatness σ=0.441~0.444, which meets the road requirements.

Not only that, SAP200C-10 has also been widely involved in the construction of a number of key domestic transportation construction projects, including Sichuan Meishan Taihe Avenue, Chengdu to Meishan Yizhou Avenue, Jiangxi Shangrao Wuyuan Jinyong Avenue, etc.

SAP200C-10 core selling points

High level

The frame screed with the torsion center coinciding with the resistance section, the back arch beam + large truss + end telescopic tensioning device is used to make the elevation angle of the end telescopic and contraction consistent with the change of the elevation angle of the main section, and the screed construction is as stable as Mount Tai.

There is no separation

The material curtain of the material baffle + spiral baffle is adopted, and the spiral blade arrangement is synchronously adopted, and the conveying material is uniformly controlled by four ultrasonic waves, so that the material level in the trough is kept highly consistent, the feeding is stable, and there is basically no segregation.

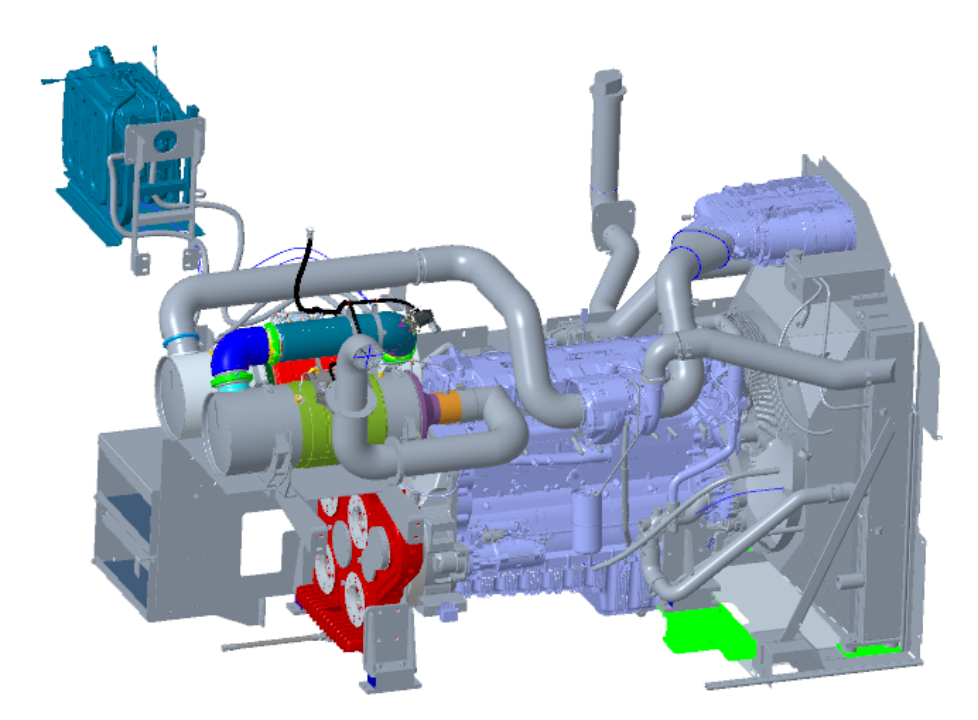

Strong motivation

The 368kW Dongfeng Cummins high-power water-cooled diesel engine matches the power requirements of driving traction, feeding width and paver width under the weight of 49 tons to meet the dual-purpose of asphalt water stability.

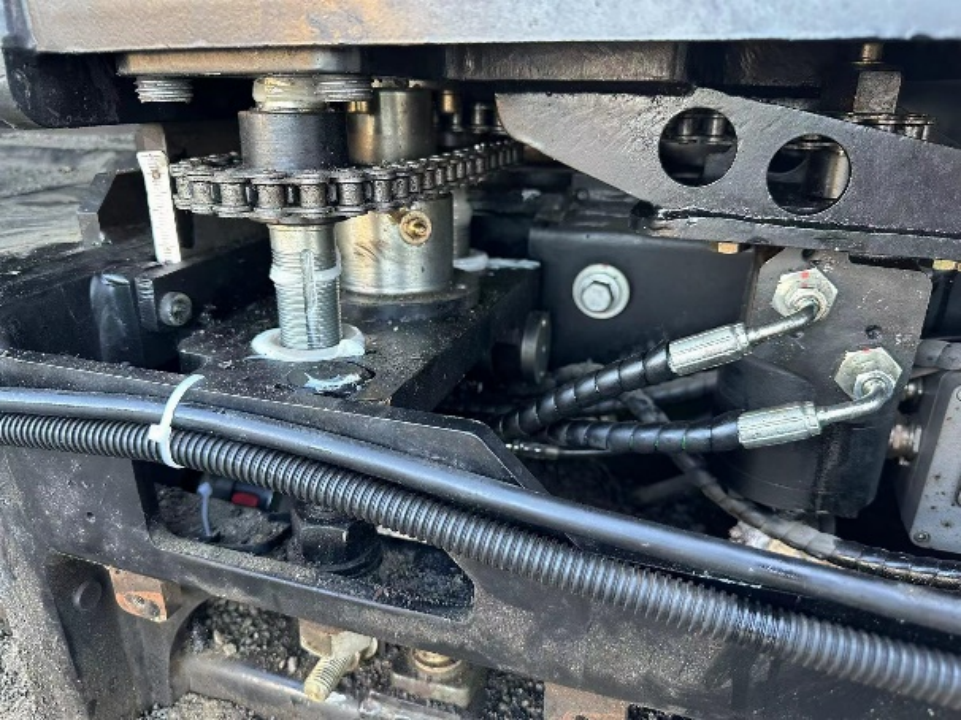

Save operation

A full range of electric adjustment (end telescopic screed, front telescopic material control baffle plate, hopper automatic receiving), greatly reduce labor intensity, 2 meters end telescopic + 1.4 meters folding spiral, no need to disassemble and assemble into the tunnel.

The SAP200C-10 20-meter paver not only represents the high-level development of road construction machinery, but also serves as a key driving force for transportation infrastructure to move towards higher quality and efficiency. With the continuous advancement of technology and the continuous expansion of the market, SAP200C-10 will continue to play a central role in more major transportation construction projects and contribute to the construction of a safer, more convenient and efficient modern transportation network. We firmly believe that in the future road construction journey, SAP200C-10 will work with industry partners to write a more brilliant chapter.

0 comments