NEW! Signed article by Xiang Wenbo!

2025.05.01

New Industrialization Research Center

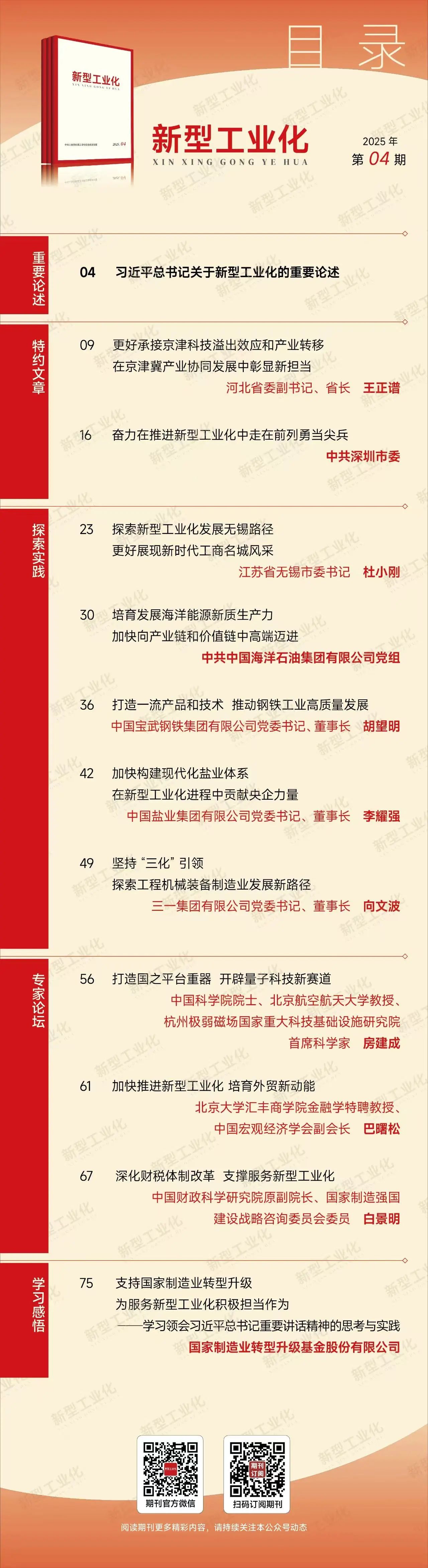

Recently, the Ministry of Industry and Information Technology's journal "New Industrialization" in 2025, Issue 4, "Exploration and Practice" column published an article signed by Xiang Wenbo, Secretary of the Party Committee and Chairman of Sany Group, and Chairman of Sany Heavy Industry, "Adhere to the Guidance of "Three Modernizations" and Explore a New Path for the Development of Construction Machinery and Equipment Manufacturing Industry.

The journal "New Industrialization" is mainly aimed at the majority of party members and cadres, theoretical workers, entrepreneurs, teachers and students of universities and scientific research institutes, and is committed to becoming an important position for publicizing and interpreting General Secretary Xi Jinping's important exposition on new industrialization, an important carrier for academic research, an important window for displaying practical results, and an important platform for tracking and exchanging the dynamic trend of a new round of scientific and technological revolution and industrial transformation.

The full text of the article signed by Xiang Wenbo is reproduced as follows:

Adhere to the "three modernizations" guidance

Explore a new way for the development of construction machinery and equipment manufacturing industrydiameter

Xiang Wenbo

General Secretary Xi Jinping pointed out that the development of new quality productivity is an inherent requirement and an important focus to promote high-quality development, and we must continue to do a good job in innovation to accelerate the development of new quality productivity. The new quality productivity has the characteristics of high technology, high efficiency and high quality, and is the internal driving force of new industrialization. In the construction machinery and equipment manufacturing industry, it is facing the "super technology window" of human society brought about by the fourth industrial revolution and the third energy revolution, through the development of new quality productivity, driving industrial upgrading and technological innovation, promoting high-end, intelligent and green industries, and injecting strong impetus into the high-quality development of the industry and the realization of new industrialization.

Sany Group Co., Ltd. (hereinafter referred to as "Sany Group") deeply grasps the rich connotation and practical requirements of new quality productivity, adheres to the enterprise development strategy of "globalization, digital intelligence, and low-carbonization", and continuously achieves breakthroughs in the fields of independent research and development, intelligent manufacturing, and market tackling, and grows into a leading enterprise in China's construction machinery and equipment manufacturing. With the forward-looking strategic layout, driven by innovation, we take the lead in exploring and practicing, leading the industry to achieve key products in global competition and cooperation, and successfully exploring a new path for China's construction machinery and equipment manufacturing enterprises to be self-reliant, self-reliant, transformation and upgrading, and green development.

1. Adhere to the development of globalization and open up a new situation with "both internal and external development".

The construction of a new development pattern with the domestic cycle as the main body and the domestic and international cycles reinforcing each other is a major decision made by the CPC Central Committee with Comrade Xi Jinping at the core in accordance with the changes in China's development stage, environment and conditions, especially the changes in China's comparative advantages.

Around 2000, most of China's construction machinery market was occupied by foreign brands. After more than 20 years of unremitting development, domestic brands have achieved a leap from catching up to leading. While occupying a dominant position in the domestic market, more and more industry enterprises have begun to face the global market stage and build global brand competitiveness.

As one of the leading domestic brand enterprises, Sany Group took the lead in trying to explore the international market as early as 2002. In recent years, based on China's headquarters, China's R&D, China's manufacturing, and China's market, combined with the characteristics of industrial development and its own reality, the company will take "globalization" as the primary strategy for current development, actively participate in global competition and cooperation, and let China's construction machinery products and services benefit the world's 8 billion people. For more than 20 years, Sany Group has made every effort to promote the global development strategy with the determination of "not going to sea, going out". Nowadays, through the allocation of global resources, Sany Group has accelerated the improvement of the global strength of the enterprise and cultivated and developed new quality productivity.

Policy guidance is the "compass" for the digital and intelligent transformation of manufacturing enterprises, and driven by the policy care of governments at all levels, Sany Group has taken the lead in actively carrying out the exploration and practice of digital and intelligent manufacturing projects in the industry. The picture shows the workshop of Sany Changsha No. 18 factory. Courtesy of Sany Group

Innovate the enterprise management model and realize the globalization of the organization. Implement the business strategy of "group-led, local operation, and service first", implement the organizational form of "platform empowerment + elite combat", and set up overseas regions and national regions as the overall strategic planning and empowerment platform at the global regional level, so as to further promote the localization of management and operation, so as to better adapt to the business environment around the world. It has established an overseas market channel system covering more than 400 overseas subsidiaries, joint ventures and agents, and the localization rate of overseas personnel is close to 70%. Establish a warehousing network of 7 domestic general warehouses in Beijing, Shanghai, Changsha, Shenyang, Zhuhai, Kunshan and Huzhou, 5 overseas regional center warehouses in Europe (Germany), the Middle East (United Arab Emirates), Latin America (Panama), North America (the United States) and Africa (South Africa), and nearly 1,000 overseas parts warehouses to improve global service capabilities.

Build a collaborative R&D system to realize R&D globalization. Build a "1+5+N" global collaborative R&D system, "1" refers to the global R&D center based on China, as the base camp of global R&D work; "5" refers to the five major R&D bases in Germany, the United States, Japan, India and Indonesia; "N" refers to N tentacles, which collect feedback market information through a global sales network and carry out positive product development according to local scenarios and customer needs. Starting from product research and development, Sany Group drives marketization with customization and supports globalization with high-end, and has realized more than 200 products on sale in overseas markets, covering more than 180 countries and regions around the world. In 2024 alone, more than 50 products will be developed and marketed for the European and American markets, more than 10 localized products will be defined, and 18 new products will be launched in the fiercely competitive international equipment market in the industry. Sany Group provides greener, more environmentally friendly, stable and reliable products to customers around the world, and mature markets such as Europe and the United States have become the fastest growing overseas market regions for enterprises. The company's products and mainstream brands in Europe and the United States in the key high-end market to form a "parallel tide" development pattern, the industrial layout gradually from the low-end to the high-end, leading the industry to achieve new breakthroughs for Chinese brands in overseas markets, especially in developed countries.

Deploy overseas localized production and realize the globalization of manufacturing. In overseas markets, in addition to continuously upgrading factories in the United States and Germany, it has also built new overseas factories in Indonesia, South Africa, Turkey and other places to accelerate the global layout of manufacturing and actively promote the replication, application and upgrading of China's intelligent manufacturing standards. Taking Sany Indonesia factory as an example, the factory has built a complete set of intelligent system system, including manufacturing operation system, warehouse management system, automated material distribution system, digital twin system, process simulation system, automatic reporting system, etc., through automatic calling, unmanned trolley distribution, visual positioning and tracking, trajectory heat map, abnormal alarm and other functions, while promoting the intelligence and efficiency of the operation process, it not only improves the safety and production efficiency of the operation, but also greatly reduces the energy consumption of the plant.

After years of exploration and development, there are now three Chinese companies in the top ten in the global construction machinery industry. The globalization of Sany Group has also entered a new stage. From the "internationalization" of simply selling domestically produced products to overseas markets at the beginning, to the "globalization" development strategy of turning product exports into industrial exports, based on China and looking at the world, we allocate R&D, manufacturing, sales, service and other resources on a global scale, so that Chinese enterprises can truly "equip" global competitiveness and help Chinese manufacturing to go overseas with high quality.

Scientifically understand the relationship between the domestic cycle and the domestic and international dual circulation, take the initiative and be good at acting, and find out the position and comparative advantages of the enterprise in the domestic cycle and the domestic and international dual circulation. At present, Sany Group's products serve more than 180 countries and regions around the world, of which it has become the first local brand in more than 30 countries and regions, and its products (at least one category) have occupied the first market share in 122 countries and regions, and in 2024, overseas business will contribute nearly half of the revenue and more than half of the profits to the enterprise, becoming the "ballast stone" to promote the high-quality development of the enterprise. Based on China's headquarters, China's R&D, China's manufacturing, and China's market, we vigorously promote the development path of organizational globalization, R&D globalization, and manufacturing globalization, and also pave a feasible path for China's construction machinery industry to develop globally.

2. Adhere to the development of digital intelligence and win the "turnaround battle" of transformation

At present, the new generation of information technology such as artificial intelligence, Internet of Things, and cloud computing is accelerating the penetration into all aspects of the economy and society. General Secretary Xi Jinping pointed out that it is necessary to grasp the opportunity of the integrated development of digitalization, networking and intelligence, and cultivate new kinetic energy with informatization and intelligence as levers; Promote the deep integration of the Internet, big data, and artificial intelligence with the real economy, and promote the fundamental transformation of the manufacturing industry model and enterprise form.

The construction machinery industry has a strong traditional manufacturing gene, facing many transformation problems such as high demand for product customization, technical bottlenecks, huge capital investment, shortage of management talents and inappropriate corporate culture. In years of business practice, Sany Group has deeply realized that no matter how difficult the road of transformation is, the only way to cope with the changes of the times is to take the initiative to embrace and seek change and innovation. In the face of the surging attack of the digital and intelligent era, the traditional manufacturing industry must continuously improve the core competitiveness of enterprises and cultivate and develop new quality productivity through technological innovation, management upgrading and cultural reshaping.

There is no successful precedent for the digital and intelligent transformation of construction machinery, how to use the new generation of information technology to "transform" the traditional manufacturing industry into advanced manufacturing, as an industry pathfinder, Sany Group regards the digital and intelligent transformation as a "either turn over, or overturn" enterprise strategic change. With the construction of "lighthouse factory" intelligent manufacturing as the core, and the four modernizations of processes, eight industrial software, data collection and application, and product electrification and intelligence as the starting point, we will finely manage manufacturing, accurately control costs, and comprehensively promote intelligent manufacturing, intelligent products and intelligent operations.

Deeply cultivate intelligent manufacturing and create a "lighthouse" in the industry. Policy guidance is the "compass" for the digital and intelligent transformation of manufacturing enterprises, and driven by the policy care of governments at all levels, Sany Group has taken the lead in actively carrying out the exploration and practice of digital and intelligent manufacturing projects in the industry. Sany Changsha No. 18 Factory Project was approved by the Ministry of Industry and Information Technology as the first batch of intelligent manufacturing pilot demonstration projects, and is committed to building it into a world-class model of intelligent manufacturing in the construction machinery industry. However, the parts of the heavy equipment manufacturing industry often weigh several tons, and at the same time have the characteristics of multi-variety and small-batch operations, which brings great challenges to the realization of intelligent manufacturing with fewer people. Sany Group has intelligently upgraded the nine major processes of pump truck manufacturing in Factory 18, breaking through a number of key core technologies such as automatic cutting and cutting, robot welding/group pairing, and the AI intelligent nesting system has increased the average utilization rate of steel in the entire enterprise by 11 percentage points, while the welding robot in the factory can control the weld at the millimeter level. At the same time, we have developed a manufacturing operation management platform (MOM) as the core, combined with multiple sets of digital systems such as workshop logistics management system (WMS), production planning system (APS), digital twin, etc., to form the "intelligent brain" of factory manufacturing, and gradually realize the digitalization of the whole process. Through process intelligence and end-to-end data flow integration, the computer dynamic decision-making, flexible configuration and precise scheduling of the three major elements in the production process - man, machine and material are successfully realized. In the No. 18 factory, the mixed production of less people has become a reality, the two general assembly lines can carry out the mixed flexible production of 69 kinds of products, relying on the in-depth application of digital technology, as large as 72 meters of booms, as small as 2 mm screws, all can be automatically assembled by robots.

Since 2019, Sany Group has invested more than 10 billion yuan to complete the intelligent manufacturing upgrade of all traditional factories. Sany Beijing Pile Driver Factory, Sany Changsha No. 18 Factory and Sany Shaoshan Blade Factory have successively obtained the "Lighthouse Factory" certification of the World Economic Forum in Davos, and the intelligent manufacturing industry has now ranked among the world's leading levels.

Upgrade intelligent products and lead the "unmanned era". The transformation of construction machinery products to data intelligent terminals is an important goal of Sany Group's digital intelligence strategy. As a means of production, the future construction machinery is bound to become a mobile intelligent terminal. Sany Group actively promotes the transformation of scientific research achievements and is committed to creating leading intelligent products. Relying on advanced technologies such as the Internet, big data, and artificial intelligence, a series of intelligent products have been launched. In 2019, the world's first 5G remote-controlled excavator jointly built by Sany Group and Huawei was unveiled to the public. Through the mobile 5G network, the staff in Shanghai started the unmanned excavator at the Luanchuan Molybdenum Mine in Luoyang, Henan Province, thousands of miles away, and the equipment smoothly carried out compound actions such as excavation, rotation and loading, which was the first case of 5G application in the global construction machinery industry. In 2024, the Sany SY550 remote-controlled excavator will be applied to emergency rescue scenarios for the first time, greatly improving the flexibility, safety and efficiency of rescue work. In recent years, in addition to the deeper application of unmanned excavators in rich scenarios such as smart mines, emergency rescue and disaster relief, and unmanned docks, the world's first unmanned mixer truck, unmanned road roller, unmanned paver, unmanned crane, unmanned tractor, fire-fighting drone and other unmanned equipment have been launched in Sany Group, leading the industry into the "unmanned intelligent era".

Guided by new quality productivity, Sany Group accelerates the exploration and practice of the strategic transformation of low-carbon enterprises, strives to achieve green development goals, and contributes to the "green power" of the equipment manufacturing industry. The picture shows Sany Group's wind farm in Ningxiang, Hunan. Courtesy of Sany Group

Promote intelligent operations and continue to explore value. On the basis of creating intelligent manufacturing and intelligent products, Sany Group continues to promote the collection of full and all-factor data, mine the value of data, and improve the efficiency of refined and intelligent operations. Not only that, intelligent operation also promotes enterprise management and customer value creation at the same time. Widely connect all kinds of equipment and systems, integrate the collection, aggregation and analysis of massive data, and realize digital twins through modeling, which promotes the optimal resource allocation and scientific and reasonable decision-making in production management, and promotes enterprises to improve quality, reduce costs and increase efficiency. In Sany Changsha No. 18 factory, more than 30TB of big data is generated in the factory every day, which is equivalent to the mobile phone network traffic of a county with a population of 200,000 in a day. Through data analysis and operation, the factory automation rate is close to 80%, the production capacity is increased by 123% compared with before the transformation, the personnel efficiency is increased by 98%, and the unit manufacturing cost is reduced by 29%.

In addition, with the help of big data and Internet of Things technology, each machine is connected to a huge network through on-board controllers, sensors and wireless communication modules, and data traces are formed with every wave of a shovel and a step. Big data accurately depicts the operating rate of infrastructure construction, and has become a weather vane for observing economic changes such as fixed asset investment. Through the C-end interconnection, the operating parameters such as the operating rate of nearly one million construction machinery and equipment have been collected massively, and the well-known "excavator index" in the industry has been launched, which can reflect the degree of economic prosperity and become an important reference basis for economic decision-making.

In the face of the widespread popularization of advanced AI applications such as large models, Sany Group promoted the exploration and practice of AI technology in enterprises for the first time. It is not only regarded as a technology, but also as a huge industry. Explore the industrial upgrading that AI technology may bring about in all fields and links of intelligent manufacturing, intelligent products, and intelligent operations. At present, all departments and positions in enterprises are required to have their own AI operation plans, and strive to realize the AI revolution from "local intelligence" to "global intelligence".

In 2022, the Ministry of Industry and Information Technology (MIIT) announced the pilot demonstration list for the integrated development of a new generation of information technology and manufacturing, and Sany Group was successfully selected as the first batch of "Digital Pilot" enterprises by virtue of its innovative practice in digital and intelligent transformation. Multiply the "number" and move forward towards the "wisdom". Sany Group will continue to accelerate the exploration and practice of digital and intelligent transformation, integrate and develop intelligent manufacturing, intelligent products and intelligent operations, make every effort to win the "turnaround battle" of digital and intelligent transformation, give full play to the demonstration and leading role of "pilot" enterprises, build a platform enterprise and ecological enterprise based on the deep integration of industrial Internet, big data and artificial intelligence technology, and create a benchmark for digital and intelligent transformation in the industry.

3. Adhere to low-carbon development and contribute to the "green power" of the equipment manufacturing industry

General Secretary Xi Jinping pointed out that green development is the background color of high-quality development, and new quality productivity itself is green productivity. We must accelerate the green transformation of the development mode and help achieve carbon peak and carbon neutrality. Green and low-carbon is the intrinsic requirement of new quality productivity, and the green and low-carbon development mechanism is an important guarantee for the development of green new quality productivity. As the core pillar industry of China's industrial system, the equipment manufacturing industry is an important engine to promote high-quality economic development, and it is also a key area to achieve the "double carbon" goal. For a long time, the green and low-carbon transformation of the construction machinery and equipment manufacturing industry has faced many lagging development problems, such as the insufficient penetration rate of new energy products, the lack of synergy in the development of new industries, and technical and economic constraints. Anchor the goal, based on yourself. Guided by new quality productivity, Sany Group accelerates the exploration and practice of the strategic transformation of low-carbon enterprises, strives to achieve green development goals, and contributes to the "green power" of the equipment manufacturing industry.

Iterate the product matrix and comprehensively develop electrified products. Sany Group will explore and practice low-carbon transformation into green and low-carbon products, make use of its deep technology accumulation and market first-mover advantage in the equipment manufacturing industry, give full play to its leading role in the industry, and comprehensively develop electrified products. Since 2021, it has taken the lead in innovating the operation and management model in the industry, and established a new energy technology committee to manage new energy technology development planning, patent layout, forward-looking technology research and industrial incubation. At present, all the traditional main engine divisions of Sany Group have established parallel electrification divisions. Comprehensively promote the electrification of main engine products and the development of related core component technologies, focus on the three major technical routes of pure electric, hybrid and hydrogen fuel, covering batteries, electric drives, electronic control, electronic appliances, control algorithms and thermal management and other fields, continue to iterate low-carbon products, and have a complete electrification product matrix.

We will continue to give full play to the advantages of the "1+5+N" global collaborative R&D system, drive R&D with the market, and define products with demand, so that the final electrified products on the market will not only be at the same frequency as the world's top level at the technical level, but also closer to the needs of first-line customers, and will be recognized by both technology and the market. In 2022, the first international dedicated electric mixer truck iONTRON408P, jointly developed by the Sany Sino-German team, successfully passed the EU model certification and was licensed, and the product has passed nearly 80 rigorous vehicle and parts certification tests, becoming the first electric construction machinery product in China to obtain the European market access qualification. In 2024 alone, Sany Group will launch a total of 101 models of 11 types of electrified products, and develop and apply 57 new technologies, including the industry's first application of vehicle-like sliding sleeve shift technology on electric loaders, successfully achieving no hydraulic lossElectric tractorMTB integrated power battery is adopted, the energy density is greatly improved, and the market response of new technologies and new products is good. In 2024, the company will take the lead in the industry to achieve sales of electrified products exceeding 10 billion yuan.

After R&D, application and market exploration in recent years, Sany Group has achieved a leading position in the field of new energy construction machinery that can be commercialized, and its products such as electric mixer trucks, electric pump trucks, electric cranes, electric dump trucks, electric port machinery, and electric heavy trucks rank first in the industry. Based on the full-category product matrix of electro-intelligent synergy, Sany Group explores and creates benchmark scenarios for the application of rich electrified products. For example, the overall solution of smart mines has been launched and applied in traditional manual projects such as coal mines, metal mines, sand and gravel aggregate mines and water conservancy projects, and the commercialization of unmanned electrified products has a cumulative operating mileage of more than 2 million kilometers and an operating earthwork volume of more than 10 million cubic meters. Effectively improve the difficult pain points such as the safety red line of traditional mines, poor environment, and employment faults, and use market-oriented commercial operation to explore and help the low-carbon and green development of society.

Optimize the industrial form and make an in-depth layout of the new energy industry. Adhere to the "two-wheel drive" of the low-carbon enterprise development strategy, grasp the products with one hand and the industry with the other, and make an in-depth layout of the new energy industry. Guided by the national "double carbon" goal, we will thoroughly implement the concept of green development, devote ourselves to promoting industrial transformation and upgrading, and contribute to the construction of national ecological civilization. Comprehensively deepen the industrial layout, widely cover low-carbon industries such as wind energy, solar energy, hydrogen energy and energy storage, accelerate the construction of a green and low-carbon development system, and aim to create a new and forward-looking green and low-carbon industrial development pattern.

Sany Renewable Energy, a wind power host company, is committed to becoming a global leader in clean energy equipment and services, and has now ranked among the top 10 in the global industry. In October 2024, China's first and the world's largest 35 MW six-degree-of-freedom wind turbine test bench was officially put into operation at the Sany Renewable Energy Wind Power Test Center. The test bench is completely independently developed and designed by Sany Renewable Energy, and is the world's largest wind turbine transmission test bench with the highest bearing power, the highest degree of reduction and the most comprehensive verification. In 2022, it officially entered the photovoltaic industry, opened up the entire photovoltaic industry chain from monocrystalline to cells and modules in only 9 months, explored the construction of a comprehensive energy system integrating photovoltaic, energy storage and diesel power, and applied it in global markets such as Zambia. In the hydrogen energy business segment, focusing on seven major technology R&D capabilities, including integration, materials, testing, simulation, process, electronic control, and hydrogen safety, it has released the world's largest single-system hydrogen electrolyzer and GW-level overall solution for green electricity hydrogen production. The energy storage battery system pioneered the magic tower stacking solution, and the battery swapping product achieved a rapid battery swap in 1.9 minutes, becoming the first in the industry.

Build a new era of dreams and set sail for a new journey. Sany Group believes that the current development of China's manufacturing industry is at the intersection of two once-in-a-lifetime opportunities: one is the Chinese dream of the great rejuvenation of the Chinese nation under the guidance of Xi Jinping Thought on Socialism with Chinese Characteristics for a New Era, and the second is the "super technology window" of human society brought about by the fourth industrial revolution and the third energy revolution. Sany Group will be guided by the development of new quality productivity, deeply understand the great significance of realizing new industrialization, adhere to independent innovation, seize opportunities, continue to stimulate new momentum for the high-quality development of enterprises and industries, and contribute to the high-quality development of the manufacturing industry.

Source: New Industrialization, Issue 4, 2025

Recommended products

Flat Top 370 (Standard Load/Composite)

Related testimonials

Xiang Wenbo × Wang Han's "Entrepreneurship Has to Talk" is here!

2025.05.20

The 2025 Changsha Exhibition has come to an end, and Sany shows the hard power of the whole industry chain!

2025.05.19

Xiang Wenbo's "Entrepreneurship has to talk" revealed the legend of entrepreneurship, Wang Han admitted frankly that 50 years old is the age of Chuang

2025.05.18

0 comments