Focusing on the G20, "What is a Sail" explores the Trinity South Africa Industrial Park

2025.11.27

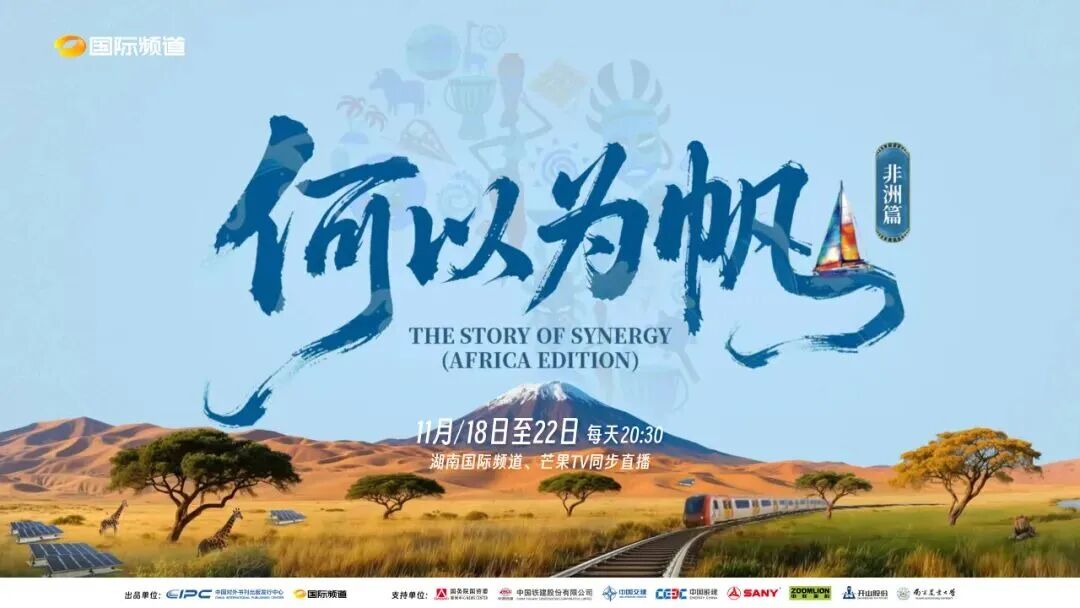

Hunan International Channel

The fourth episode of the second season of the "Protecting the Blue Planet, Enterprises in Action" series of themed documentaries "What is a Sail", "The Light of Manufacturing" - walked into the Sany South Africa Industrial Park and started a dialogue on "Manufacturing Foundation and Intelligent Manufacturing Future".

In the "African Moment" of the G20, the African chapter of "What is a Sail" is specially supported by the Information Center of the State-owned Assets Supervision and Administration Commission of the State Council, and jointly produced by the China Foreign Languages Publishing and Distribution Center of the China Foreign Languages Bureau and the International Channel of Hunan Radio and Television Station.

South African Industrial Park

"China Speed" and Localization Practices at the G20 Moment

In Johannesburg, an industrial park covering an area of about 30,000 square meters is rising from the ground. This South African industrial park, which integrates manufacturing, logistics and talent center, takes a key step in Sany to achieve localized manufacturing in Africa.

Arnold, a graduate of Beijing Institute of Technology, is the project's external liaison officer and is fluent in Chinese to communicate with Chinese infrastructure engineer Zeng Xiangshun. "When I translated the documents, I found that the design in China was not the same as the design in South Africa." Arnold said. One drawing, two specifications, in countless Q&A, adjustment and confirmation, together outline the outline of the future.

"He has systematically studied the proper terms of architecture, so the translation accuracy is very high." Zeng Xiangshun commented on his partner.

Arnold is proud of this: "My work may seem small, but it proves that industrial park projects can be implemented in South Africa according to our local standards. I am very happy and honored to be a part of it. ”

Host Center

World-class standards and the growth of African talent

"Pre-delivery inspection is not only technical work, but also a responsibility and commitment." At the main engine center, mechanical engineer Sibusiso Nkabinde is making the final confirmation of a new machine that will be delivered.

Five years ago, he was a college graduate who knew nothing about construction machinery. He has obtained additional professional certifications through his apprenticeship at Sany and has grown into a skilled backbone. "The equipment will be used to build bridges, build infrastructure, and support projects across Africa...... The inspections we do are to ensure the safety of the operators and ensure that the machine moves forward smoothly. ”

Xue Bufei, operation manager of the main engine center, commented on him: "Young, but experienced. Here, global unified standards and localized needs are deeply integrated, and local engineers can not only complete mechanical assembly and maintenance, but also participate in personalized debugging and adaptation of equipment.

At a road construction site more than 100 kilometers away from Johannesburg, local customer Rainier van Driest knows it well: "The machines are easy to operate, well-designed and easy for operators to get started. Approximately every 250 hours of operation, the service team will come to the home for a routine inspection to ensure that the equipment is free of any malfunctions. No matter how big or small, they can solve them quickly. ”

Accessory Center

From "Accessory Arrival" to "Trust Arrival"

"If the warehouse is in stock, the customer can come to pick it up an hour after placing the order." Liang Dong manages Sany's largest parts center warehouse in southern Africa. The local satisfaction rate here is as high as 90%, forming a service network across southern Africa, allowing parts to go directly from Johannesburg to Zimbabwe, Mozambique, Zambia, Botswana and other African countries.

Behind the efficiency is the coordinated development of the local team and the Chinese system. Mbulero Dengge, head of the shipping department, learned almost from scratch: "All the systems I use now are learned at Trinity, and most of the system interfaces are in Chinese. ”

Johannes Meier, an agent who has worked with Sany for 16 years, feels this efficiency firsthand: "Sany has an accessories warehouse in Ten Pisa, about 30 minutes from us. If you receive an order that we do not have in stock, send a driver to pick it up after placing the order, and it will be delivered within two hours. ”

Every on-time delivery is consolidating trust. This largest parts center in Southern Africa is like an engine that drives local operations and service capabilities, intertwining the growth trajectories of countless African partners and weaving a win-win bond of destiny for both parties.

Skills training and new energy

"Intelligent Classroom" for Africa's Future

"We have training every week." Ye Yifu, Director of Service Support Department of Sany South Africa, introduced. In the training center, students from different positions are having a heated discussion.

William Dessel has gained a lot from the class: "They gave us a lot of training to better understand the product and how the machine works, and to pass that knowledge on to customers and other technicians. ”

"Hand in hand" teaching has enabled many African young people to achieve transformation. Not only did Sibusiso grow from an apprentice to a technical backbone, but it also changed the accessories centerforkliftOperator Sasha Mordik's career trajectory: "Because I was not familiar with the industry before, my Chinese colleagues were not strict, but taught us step by step, and they were really good. ”

At the same time, green and low-carbon technologies are being implemented in South Africa - new energy training courses continue to advance, photovoltaic panels in the industrial park shine in the sun, Sany electric heavy trucks have completed the first batch of deliveries in Africa, and more electric excavators, mining trucks, and cranes will be put into application in the future...... The green background of China's intelligent manufacturing is quietly integrating into Africa's development picture.

"This is not just an ordinary building," Arnold said, "it represents a turning point for green and clean development in Africa." ”

From the first Chinese construction machinery to the hot land of Africa, to the rise of the industrial park today, more and more Chinese manufacturing enterprises are connected with African opportunities, integrating advanced technical standards and perfect industrial chains into the local area.

Source: Hunan International Channel

0 comments