Sany Heavy Industries Sany Heavy Industry (SH:600031)

Trinity International Sany International (HK:00631)

Trinity Renewable Trinity Renewable Energy (SH:688349)

Home > Trinity News > Sany Heavy Industry Pile Crane Factory was awarded the first "lighthouse factory" in the global heavy industry

Sany Heavy Industry Pile Crane Factory was awarded the first "lighthouse factory" in the global heavy industry

2021.09.27

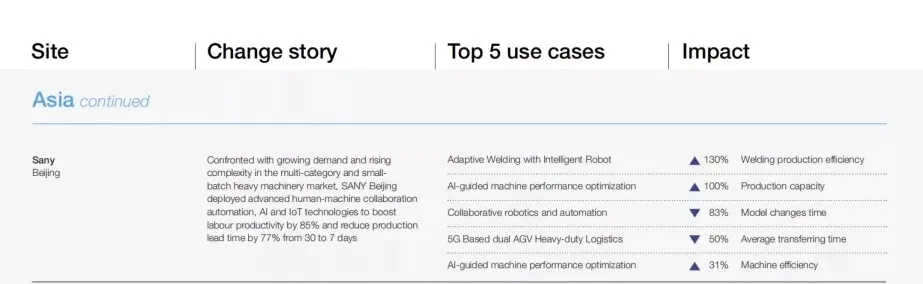

On September 27, the World Economic Forum (WEF) officially released a new list of "lighthouse factories" in the global manufacturing field, and Sany Heavy Industry's Beijing pile rig factory was successfully selected, becoming the first certified "lighthouse factory" in the global heavy industry industry.

The world's first!It represents the strength of China's manufacturing in the heavy industry industry

The Lighthouse Factory, known as the "world's most advanced factory", is a demonstrator of "digital manufacturing" and "globalization 4.0" jointly selected by the World Economic Forum in Davos and McKinsey & Company, representing the highest level of intelligent manufacturing and digitalization in the global manufacturing field today.

According to the official note of the Global Lighthouse Network, the Global Lighthouse Network is a community organization of production plants and other facilities that is a world leader in adopting and integrating cutting-edge technologies of the Fourth Industrial Revolution (4IR). The individual "lighthouse factories" that make up the lighthouse network refer to the leading enterprises that have been effective in the integration of cutting-edge technologies in the Fourth Industrial Revolution and can be regarded as a global example.

Since the launch of the project in 2018, 90 "lighthouse factories" have been certified worldwide, including the 21 shortlisted factories. In the global "lighthouse factory" network, there are a total of 29 in Chinese mainland, distributed in 3C electronics, home appliances, automobiles, steel, new energy and other industries. China is also the country with the most "lighthouse factories", which once again confirms the strong strength of Made in China. The Beijing pile rig factory of Sany Heavy Industry is the first world lighthouse factory in the global heavy industry industry, representing the hard core strength of Made in China in the heavy industry industry.

Picture丨The World Economic Forum spoke highly of the Sany Lighthouse factory

The official website of the World Economic Forum introduces the reason for the selection of Sany Pile Machinery Factory: In the face of the changing and increasingly complex needs of the multi-variety and small-batch construction machinery market, Sany uses advanced human-machine collaboration, automation, artificial intelligence and Internet of Things technology to increase labor productivity by 85% and shorten the production cycle from 30 days to 7 days, a reduction of 77%.

Picture丨Inside the "Lighthouse Factory" of Sany Pile Crane

For this global high-standard certification, Mr. Liang Wengen, chairman of Sany Heavy Industry, said: Beijing pile rig factory has become the world's lighthouse factory, a new business card of Sany, a milestone in Sany's digital transformation, and a key step for Sany to become a pioneer in intelligent manufacturing.

The industry believes that being rated as the world's "lighthouse factory" reflects Sany's outstanding achievements and "leader" strength in advanced manufacturing and digital transformation, and marks that Sany has won the opportunity in the competition of the fourth industrial revolution.

Pile Mechanics, the world's leading!

Picture丨Sany pile machine products

Sany Heavy Industry Beijing Pile Rig Factory is located in Nankou Industrial Park, Changping District, Beijing, covering an area of 40,000 square meters, is the world's largest pile machinery manufacturing base, and is also one of the factories with the highest degree of intelligence, the highest per capita output value and the lowest unit energy consumption in the global heavy industry industry.

The rotary drilling rig produced by Beijing Pile Rig Factory is Sany's trump card product, and it is also a "single champion product in the manufacturing industry" certified by the Ministry of Industry and Information Technology. At present, the global market share of Sany rotary drilling rigs has ranked first for 10 consecutive years, and one out of every three rotary drilling rigs in China is manufactured by Sany. Overseas, it is exported to more than 60 countries and regions such as Brazil and Thailand, and is highly recognized by global customers.

Flexible intelligent manufacturing!Intelligent production level has become a global "lighthouse"

Figure丨Flexible assembly island

As heavy equipment, the production mode of pile construction machinery is typical discrete manufacturing, with multiple varieties, small batches, and complex processes. The bigger challenge is the complexity of the workpiece, which is large, heavy and long, such as the longest of more than 170 drill pipes weighing 27 meters and weighing 8 tons, and more than 20 types of power heads weighing up to 16 tons.

After automation, digitalization and intelligent upgrading, Sany Pile Machinery Factory has a total of 8 flexible work centers, 16 intelligent production lines, and 375 fully networked production equipment. Based on the tree root interconnection industrial Internet platform, the production and manufacturing elements are fully connected, and the entire factory has become an "intelligent body" that deeply integrates the Internet, big data and artificial intelligence.

First of all, the Sany pile machine factory has an "intelligent brain" - FCC (factory control center), which is also the core of the intelligent manufacturing of the entire factory. Through FCC, orders can be quickly broken down into each flexible production line, every work island, every equipment, and every worker, realizing the whole process from order to delivery. Along the data flow, the product can "understand" the whole process and details of its manufacture.

Figure丨Intelligent assembly

Machine vision systems are the ubiquitous "eyes" in factories. With the help of 2D/3D vision sensing technology, AI algorithms and high-speed 5G networks, the pile rig factory has realized the in-depth application of intelligent industrial robots in the fields of adaptive welding and high-precision assembly of large-scale equipment, and solved many world problems such as "unmanned assembly of 16-ton power head" and "multi-layer single-lane continuous welding of drill pipe square head with a thickness of 40mm and a width of 60mm".

At present, in this factory, the sorting of small steel plates and the assembly of masts as large as more than ten tons can all be automated by robots.

Figure丨Dual AGV linkage based on 5G

The realization of smart logistics is handed over to the smart cargo handling "Scud" - AGV trolley. Under the guarantee of accurate timing and low latency 5G wireless industrial private network, the industry pioneered the "two-vehicle dream linkage" of two AGVs to realize the synchronous handling and automatic loading and unloading of 27-meter ultra-long and heavy materials.

Figure丨Intelligent welding

The "brain", "eyes" and "scud" efficiently and collaboratively decompose tasks, and the "hands" of the smart factory are also running at a rapid pace. In factories, "human-machine collaboration" technology based on 5G+AR equipment has been widely used. Traditional labor and dangerous work such as material sorting and pin assembly no longer require manual operation, and are all efficiently completed by robots.

At the same time, through strong human-machine collaboration, robot AI can also learn the skills and techniques of skilled workers without programming, and use it as a comprehensive teaching aid to "lead the old with the new", and finally realize the transfer of skills and the inheritance of the craftsmanship spirit of the "master" of the factory.

Figure丨Flexible welding island

In the background, the "root cloud platform" created by Tree Root Internet is also calculating day and night, which should match the optimal parameters for each process, each model, and even each tool according to the industrial big data collected by more than 36,000 collection points in the factory, and optimize the production cycle.

Dong Mingkai, president of Sany Intelligent Manufacturing Research Institute, introduced: "Today's pile rig factory is a smart and quick-eyed engineer, which has realized the parameterization and software of craftsman spirit and experience."

Highly flexible production allows production potential to be maximized. Compared with before the transformation, the output value of the pile rig factory in the same plant area has doubled, the overall production equipment operation rate has increased from 66.3% to 86.7%, and the average failure time has decreased by 58.5%. At present, the factory can produce nearly 30 models, and the level of "flexible intelligent manufacturing" is leading in the world, realizing "elephant dancing".

In 2020, the per capita output value of Sany Pile Machinery Factory has reached 10.728 million yuan, which is a well-deserved "lighthouse benchmark" in the global heavy industry industry.

Dong Mingkai said that the pile rig "lighthouse factory" took the lead in adopting the "Industry 4.0" standard in the industry, creating a benchmark for smart factories in the global industry, and setting a positive example and demonstration for the construction of other "lighthouse factories" in the global industry.

Unprecedented!Sany digital transformation has reached a new level

Picture丨Aerial photography of Sany pile machine "lighthouse factory"

In 2018, at the fourth "representative channel" of the first session of the 13th National People's Congress, Liang Wengen, deputy to the National People's Congress and chairman of Sany Heavy Industry, said that in the face of the digitalization of construction machinery and manufacturing, Sany "either capsized or turned over".

In 2019, as the first batch of lighthouse factory demonstration bases of the group, Sany Pile Factory fully launched the intelligent manufacturing upgrade work to explore the deep integration of digital technology and the industrial field.

To build the industry's first world-class "lighthouse factory", there is no technical precedent and no mature supplier. In order to achieve the set goals of the lighthouse factory, Sany has set up a special intelligent research institute, which has become the "vanguard" of Sany's digital transformation strategy.

Whether it is summer or winter cold, or in the face of the challenges of the epidemic, the vanguard carries forward the "lighthouse spirit" and has never stopped on the road of building the "lighthouse factory". From directors and executives to craftsmen, designers, programmers, inspectors and skilled workers on the spot, countless people work tirelessly on the front line to turn the impossible into possible.

After nearly two years of planning, design and construction, and overcoming thousands of problems, Sany has done an unprecedented thing - the monthly production capacity of the pile rig "lighthouse factory" exceeded 300 units, successfully reaching production and exceeding production, marking a new level of Sany's digital transformation.

"In the construction of the lighthouse factory, it not only cultivates a group of talents, but also provides the industry with Sany experience and thinking on the implementation of intelligent manufacturing," said Dai Qinghua, director and senior vice president of Sany Group. ”

Hundreds of people and billions!Play the leading role of a world-class "lighthouse factory"

Picture丨Sany pile machine products

Walking into the pile machine factory and standing next to the production line, you can find the reasons why this can be done: the culture of every second, the tight production, the innovation that dares to be the first, and the huge expansion of Chinese brands under the wave of digitalization. It is this scale effect and profound scientific and technological strength that push Sany Heavy Industry to the position of a global leader in advanced manufacturing.

It can be said that the transformation of the pile rig factory is a microcosm of Sany's promotion of digital strategic transformation in the past three years, and it is also the fruit of Sany to truly achieve user-centered and data-driven connection of the whole value chain operation. In response to the cyclical challenges of the industry, Sany is making great strides towards a digital enterprise of "product + service" through digital transformation.

At present, in addition to the Beijing pile machine factory, Sany has invested more than 12 billion yuan to launch 46 intelligent manufacturing lighthouse factories and intelligent production line projects in Changsha, Kunshan, Chongqing and other industrial parks, and has realized the real-time interconnection of nearly 10,000 production equipment and more than 100,000 materials.

Dai Qinghua, director and senior vice president of Sany Group, said that Sany Pile Crane Lighthouse Factory will continue to deepen digital transformation, build a "100 people and 100 billion" lighthouse factory in the heavy industry industry, and help Sany Group achieve the "Three Threes" strategic goal: at the end of the "14th Five-Year Plan", the whole group will achieve 300 billion sales, 3,000 workers and 30,000 engineers.

In response to the national intelligent manufacturing strategy, vigorously developing the industrial Internet, and further promoting intelligent manufacturing, Sany is committed to becoming a pioneer in intelligent manufacturing. At the same time, Sany's many experiences in building a "lighthouse factory" will also achieve capacity spillover, empower industrial chain partners, the industry, and even the entire "Made in China", and effectively play the leading role of a world-class "lighthouse factory".

Recommended products

Related recommendations

CCTV three consecutive reports! How to activate new manufacturing momentum in Sany "lighthouse factory"

2025.10.30

Gu Jiong, Secretary of the Party Committee and Director of Changsha Customs, and his delegation visited Sany Group

2025.10.29

The annual meeting of Sany Group on digital intelligence was successfully held

2025.10.27

0 comments