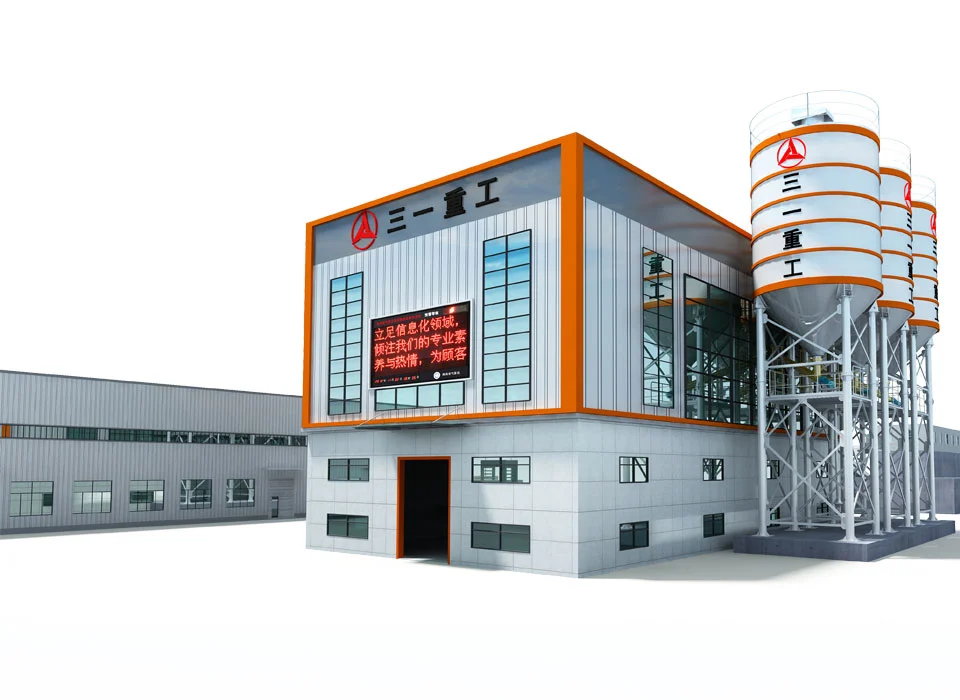

Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

HTZ5000 type

Mixing plant for HTZ5000 type backfill

150m³/h

Applicable working conditions

Product Brochure Earthworks

Earthworks Stone works

Stone works Waste disposal

Waste disposalProduct Details

Construction case

Performance parameters Product selling point

Theoretical production efficiency

150m³/h

Theoretical productivity

150m³/h

Mixer model

JS5000

Stirring motor power

2×75kW

Mixer nominal capacity

\L

Aggregate maximum particles

80mm

Powder bin capacity

(0~3)×500t

Batching capacity of the batching station

5L

Aggregate bin capacity

\m³

Aggregate type

2

Aggregate belt conveyor productivity

\t/h

Maximum productivity of screw conveyor

\t/h

Discharge height

\m

Installed capacity

410kW

Cumulative aggregate weighing range and accuracy

(900~4500)±2%kg

Cement weighing range and accuracy

(600~2000)±1%kg

Fly ash weighing range and accuracy

(330~1100)±1%kg

Water weighing range and accuracy

(750~2500)±1%kg

Weighing range and accuracy of admixtures

(45~150)±1%kg

1. Ring beam structure of powder tank

1. The gangue buffer bin adopts a self-locking structure

At the same time, the sensor is added to avoid multiple coils going down to the host at the same time

2. The inclined belt increases the coulter structure

It is convenient to clear the warehouse, avoid the agglomerate of gangue in the aggregate silo when the work is stopped for a long time, reduce the cleaning work, and avoid the cleaning accident;

The electrical layout and line installation fully consider safety, and safety switches are installed in many places to reduce the danger to personnel;

The layout of the building space is newly designed, and the operation and maintenance are unimpeded.

2. The top of the powder bin adopts a pulse bag type dust collector

1. The top of the powder bin adopts a pulse bag type dust collector

Increase the effective filtration area and filtration wind speed, easy to clean and check the agglomeration;

2. Closed stone grinding hopper

The forced laminated bag dust collector is more suitable for working conditions with high moisture content, which is easier to clean and thorough dust removal;

There is a fault emergency treatment pool to prevent the impact of abnormal waste materials on the environment;

The belt conveyor is fully enclosed for conveying, and there is no dust overflow.

1. The gangue buffer bin adopts a self-locking structure

At the same time, the sensor is added to avoid multiple coils going down to the host at the same time

2. The inclined belt increases the coulter structure

It is convenient to clear the warehouse, avoid the agglomerate of gangue in the aggregate silo when the work is stopped for a long time, reduce the cleaning work, and avoid the cleaning accident;

The electrical layout and line installation fully consider safety, and safety switches are installed in many places to reduce the danger to personnel;

The layout of the building space is newly designed, and the operation and maintenance are unimpeded.

2. The top of the powder bin adopts a pulse bag type dust collector

1. The top of the powder bin adopts a pulse bag type dust collector

Increase the effective filtration area and filtration wind speed, easy to clean and check the agglomeration;

2. Closed stone grinding hopper

The forced laminated bag dust collector is more suitable for working conditions with high moisture content, which is easier to clean and thorough dust removal;

There is a fault emergency treatment pool to prevent the impact of abnormal waste materials on the environment;

The belt conveyor is fully enclosed for conveying, and there is no dust overflow.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all