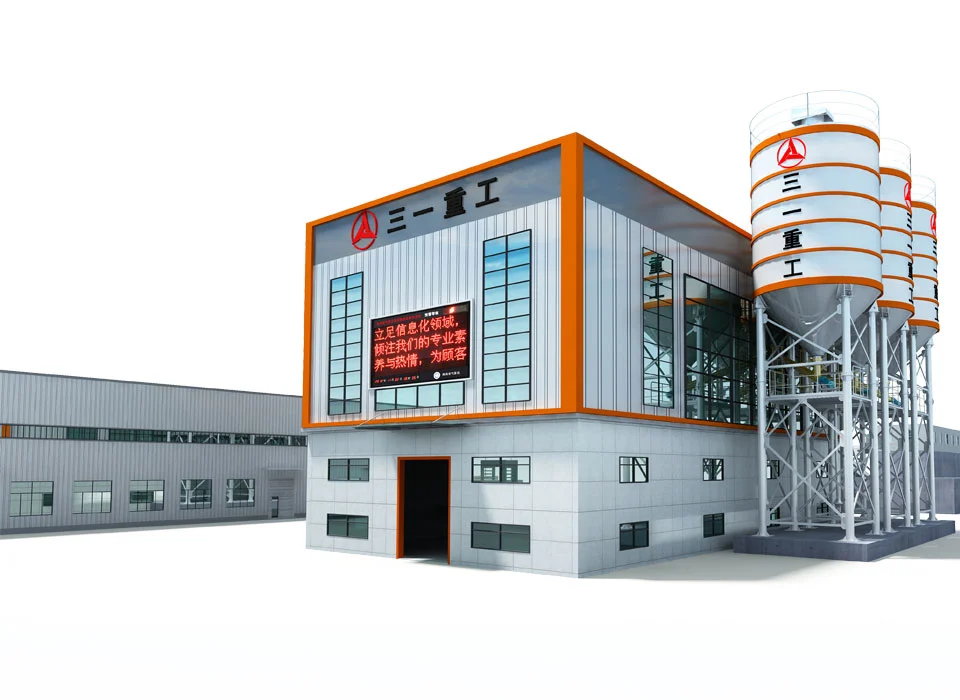

Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

HLS300H8

H8 Mixing Building

300m³/h

Applicable working conditions

Product Brochure highway

highway Housing construction

Housing construction Other works

Other worksProduct Details

Construction case

Performance parameters Product selling point

Theoretical production efficiency

300m³/h

Theoretical productivity

300m³/h

Mixer model

JS5000

Stirring motor power

2x75kW

Mixer nominal capacity

5000L

Aggregate maximum particles

Φ 80mm

Powder bin capacity

4x300t

Aggregate bin capacity

4x75m³

Aggregate type

4

Discharge height

≥3.8m

Installed capacity

440kW

Cumulative aggregate weighing range and accuracy

(900~5000)kg±2%kg

Cement weighing range and accuracy

(400~2600)kg±1%kg

Fly ash weighing range and accuracy

(300~1800)kg±1%kg

Water weighing range and accuracy

(200~1200)kg±1%kg

Weighing range and accuracy of admixtures

(20~100)kg±1%kg

1. Green

1. The discharge hopper is equipped with a rotary throttle valve, and the concrete enters the mixer truck with zero drop, without splashing; No dripping of storage material; There is no need to adjust the mixer discharge time frequently.

2. The new forced pulse bag box dust collector is treated with anti-rust technology on the surface, with high appearance and high configuration; Dust collection points are set on the top of the main engine, metering bucket and aggregate silo to effectively reduce the dust in the main building.

3. The special screw silent air compressor for the mixing building has the protection level improved, and the noise is reduced to less than 70 decibels.

Second, efficient

1. The aggregate bin is overheaded, saving the aggregate conveying time.

2. The main engine adopts a full-opening discharge door, which increases the unloading speed by 15% and reduces the residual material by 50%.

3. The arc bucket valve is used to optimize the length-to-width ratio to ensure the rapid discharging and batching of aggregates.

3. Reliable

1. Optimize the aspect ratio and discharging procedure of the powder discharge port of the main engine to reduce the phenomenon of the main engine holding the shaft.

2. The aggregate batching hopper adopts an internal vibration structure to solve the phenomenon of material blockage.

1. The discharge hopper is equipped with a rotary throttle valve, and the concrete enters the mixer truck with zero drop, without splashing; No dripping of storage material; There is no need to adjust the mixer discharge time frequently.

2. The new forced pulse bag box dust collector is treated with anti-rust technology on the surface, with high appearance and high configuration; Dust collection points are set on the top of the main engine, metering bucket and aggregate silo to effectively reduce the dust in the main building.

3. The special screw silent air compressor for the mixing building has the protection level improved, and the noise is reduced to less than 70 decibels.

Second, efficient

1. The aggregate bin is overheaded, saving the aggregate conveying time.

2. The main engine adopts a full-opening discharge door, which increases the unloading speed by 15% and reduces the residual material by 50%.

3. The arc bucket valve is used to optimize the length-to-width ratio to ensure the rapid discharging and batching of aggregates.

3. Reliable

1. Optimize the aspect ratio and discharging procedure of the powder discharge port of the main engine to reduce the phenomenon of the main engine holding the shaft.

2. The aggregate batching hopper adopts an internal vibration structure to solve the phenomenon of material blockage.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all