Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

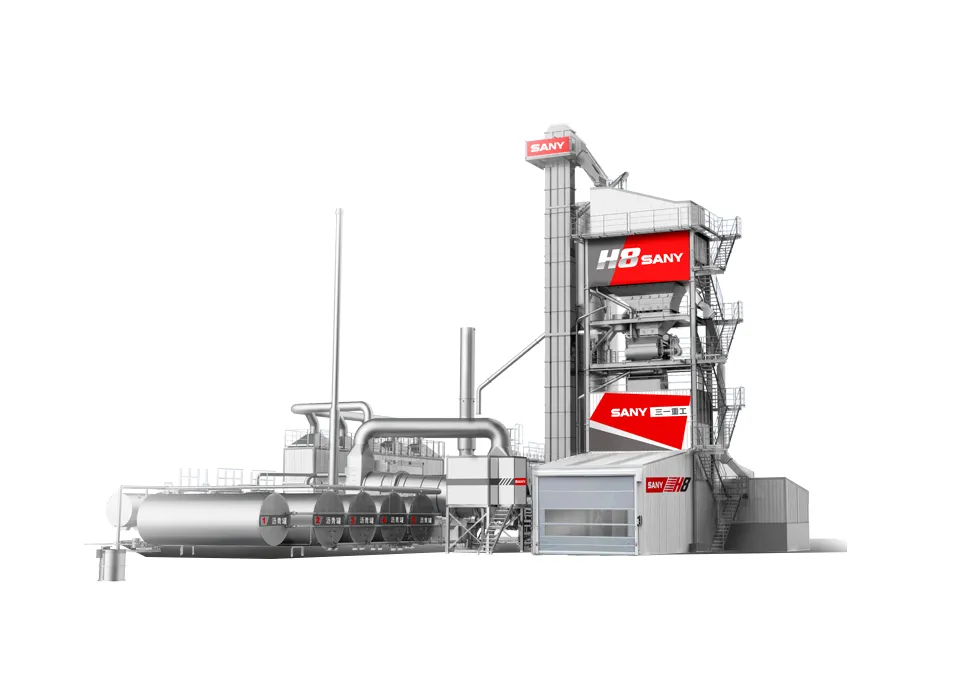

SLBH8

Asphalt environmental protection station

Applicable working conditions

Product Brochure  mine

mine highway

highway Railway/tunnel construction

Railway/tunnel construction Quarrying aggregates

Quarrying aggregates Municipal utilities

Municipal utilitiesProduct Details

Construction case

Performance parameters Product selling point

1. Dust-free main building:

The asphalt station is environmentally friendly: flap door material distribution technology, cancel the fully enclosed production of the trolley, and no dust leakage

Quadruple negative pressure vacuuming: negative pressure vacuuming in the material channel, strong pressure vacuuming at the moment of unloading of the main engine, local directional vacuuming of finished material discharge, measurement and stirring "mutual pressure relief".

2. Direct combustion of flue gas

Strong trapping: annular porous dust collection technology, independent valve control without trapping dead angles, accurate and controllable air volume, pipeline simulation and optimization, pressure loss reduced by 30%.

Pyrolysis and oxidation: the flue gas reaches the center of the flame directly, 1800°C (the reaction temperature is only 760C), direct pyrolysis and oxidation, no secondary pollution.

3. The receiving channel is fully sealed

Extra-long receiving channel, front and rear rolling shutter doors, fully enclosed material receiving of material trucks, flue gas and dust are in a static pressure state, and the adsorption effect is better.

The asphalt station is environmentally friendly: flap door material distribution technology, cancel the fully enclosed production of the trolley, and no dust leakage

Quadruple negative pressure vacuuming: negative pressure vacuuming in the material channel, strong pressure vacuuming at the moment of unloading of the main engine, local directional vacuuming of finished material discharge, measurement and stirring "mutual pressure relief".

2. Direct combustion of flue gas

Strong trapping: annular porous dust collection technology, independent valve control without trapping dead angles, accurate and controllable air volume, pipeline simulation and optimization, pressure loss reduced by 30%.

Pyrolysis and oxidation: the flue gas reaches the center of the flame directly, 1800°C (the reaction temperature is only 760C), direct pyrolysis and oxidation, no secondary pollution.

3. The receiving channel is fully sealed

Extra-long receiving channel, front and rear rolling shutter doors, fully enclosed material receiving of material trucks, flue gas and dust are in a static pressure state, and the adsorption effect is better.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all