Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

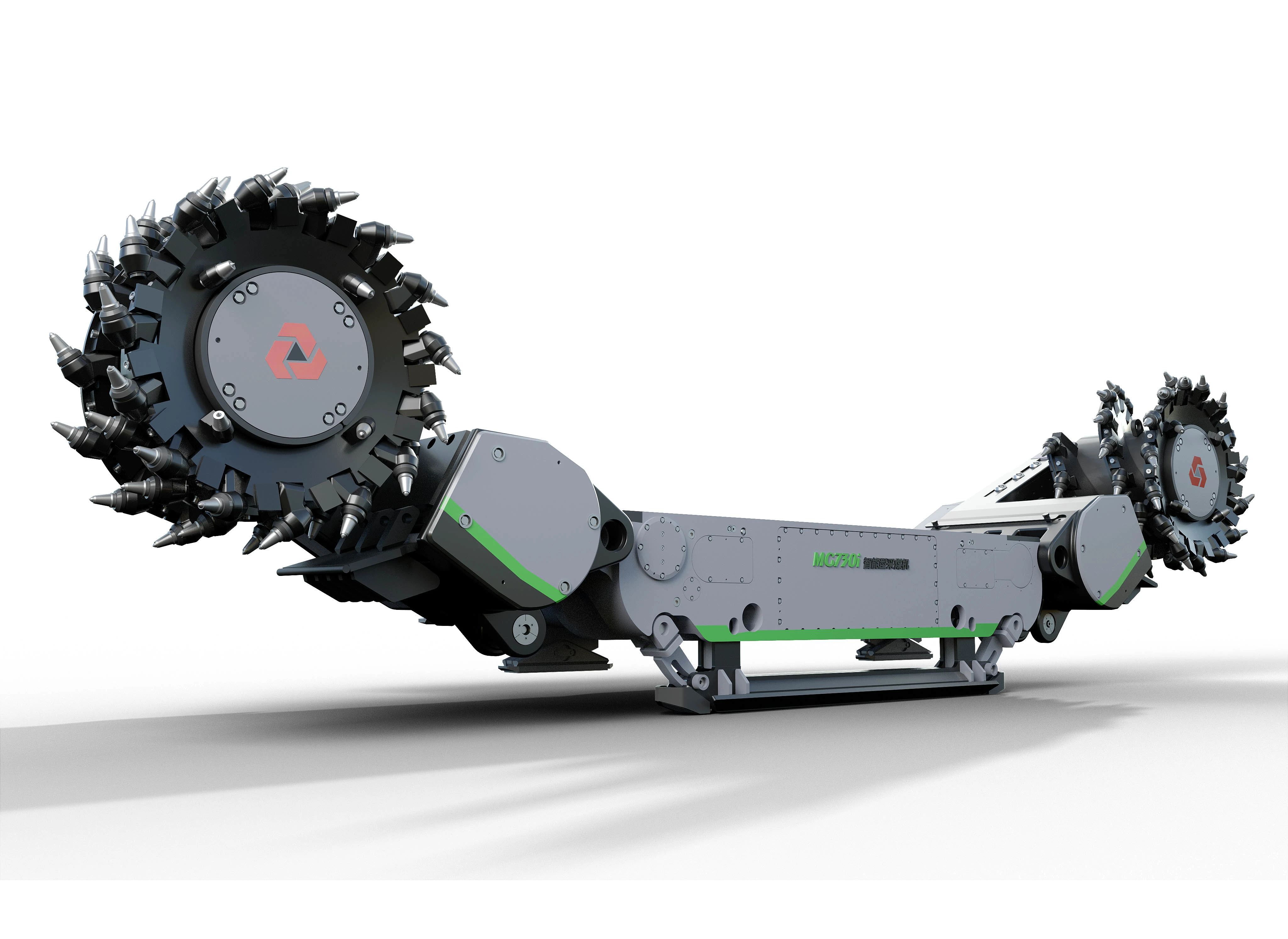

Product Details

Construction case

Performance parameters Product selling point

The length of the body

13872mm

The body is wide

1285mm

The body is high

1364mm

The quality of the whole machine

45t

Height of the surface

1202 (according to the package) / 1418 (according to the package) mm

The height of the coal

447 (according to the package) / 662 (according to the package) mm

Undercover volume

442 (according to the package) / 361 (according to the package) mm

Truncated depth

630/800mm

Drum speed

33.2rpm

Maximum non-detachable size

3020×1220×825mm

Maximum non-detachable weight

4.075t

Equipped with conveyor

SGZ730、SGZ764/GZ800

Mining height range

1900~4000mm

Working face inclination

≤35°/ ≤55°

Coal hardness

f≤4

Total installed power

610/710kW

Total cutting power

2×250/300kW

Traction power

2×45/55kW

Pump power

20kW

Supply voltage

1140v

Traction form

Gear-pins

Towing speed

0~8.5m/min

Traction

504/616kN

Manipulation methods

Hand control, remote control

Electrical control

Motion controllers

Core Benefits:

The configuration is high

The whole machine is highly configured, and imported products are used for bearings, hydraulic pumps, hydraulic valve groups, key seals and main electrical components.

Versatility

The installation of electrical components adopts a modular structure, and the internal transmission parts of the rocker arm, the internal transmission parts of the traction box, the internal transmission parts of the walking box, the sliding shoes, the oil cylinder, etc. can be interchangeable left and right.

High adaptability

It can meet the requirements of 2.0 m ~ 3.7 m and a variety of working conditions.

High reliability

Rocker shell quenching and tempering treatment: the guide sliding shoe adopts high-strength wear-resistant materials, imported bearing configuration, and a comprehensive and advanced test system.

Ease of maintenance

Maintenance-free copper sleeve, centralized oil injection, electrical parts installation adopts drawer structure, interception motor, traction motor, motor, height pump, oil cylinder, walking box and airborne electrical control parts can be extracted from the old pond side.

Automation and intelligence

Constant power automatic control, gas overrun alarm, danger value protection, fault inquiry and diagnosis, voice warning alarm, active memory cutting, rocker arm predictive maintenance.

The configuration is high

The whole machine is highly configured, and imported products are used for bearings, hydraulic pumps, hydraulic valve groups, key seals and main electrical components.

Versatility

The installation of electrical components adopts a modular structure, and the internal transmission parts of the rocker arm, the internal transmission parts of the traction box, the internal transmission parts of the walking box, the sliding shoes, the oil cylinder, etc. can be interchangeable left and right.

High adaptability

It can meet the requirements of 2.0 m ~ 3.7 m and a variety of working conditions.

High reliability

Rocker shell quenching and tempering treatment: the guide sliding shoe adopts high-strength wear-resistant materials, imported bearing configuration, and a comprehensive and advanced test system.

Ease of maintenance

Maintenance-free copper sleeve, centralized oil injection, electrical parts installation adopts drawer structure, interception motor, traction motor, motor, height pump, oil cylinder, walking box and airborne electrical control parts can be extracted from the old pond side.

Automation and intelligence

Constant power automatic control, gas overrun alarm, danger value protection, fault inquiry and diagnosis, voice warning alarm, active memory cutting, rocker arm predictive maintenance.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all

mine

mine