Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

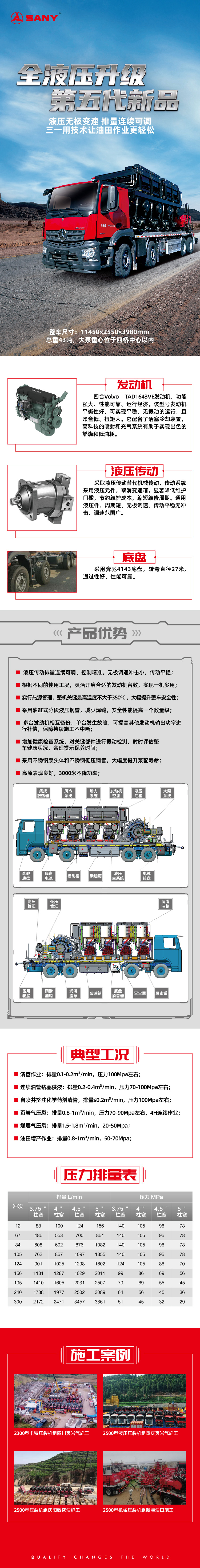

SYN5412TYL1700

Model 2300 hydraulic fracturing truck

40800kg

1700/2300KW/hp

105

Applicable working conditions

Product Brochure Fracturing acidification

Fracturing acidification Petrochemical

PetrochemicalProduct Details

Construction case

Performance parameters Product selling point

Overall dimensions (length × width × height)

11500×2000×4000mm

Total weight of the device

40800kg

Maximum operating pressure

70-4.5"Mpa

Maximum output flow

3000-4.5"L/min

Maximum output water power

1700/2300KW/hp

On-stage engine power

3×768(3×565)@1900KW(HP)

High-pressure manifold system

105Mpa

Total weight of the device

40800kg

Maximum output water power

1700/2300KW/hp

High-pressure manifold system

105

1. The hydraulic transmission displacement is continuously adjustable, the control is accurate, the impact of stepless speed regulation is small, and the transmission is stable;

2. According to different working conditions, flexibly open the appropriate number of engines to achieve multi-purpose of one machine;

3. Implement heat source management, and the key maximum temperature of the whole machine is not more than 350 °C, which greatly improves the safety of the whole vehicle;

4. The use of cylinder-type segmented hydraulic steel pipe reduces welds and improves safety performance by an order of magnitude;

5. Multiple engines back up each other, and if a single engine fails, the output power of other engines can be increased to compensate for continuous construction;

6. Add a health check system to detect the vibration of key components, evaluate the health status of the vehicle from time to time, and reasonably prompt the maintenance time;

7. Stainless steel pump head body and stainless steel low-pressure steel pipe are used to greatly improve the life of the pump;

8. The plateau performance is good, and the power does not drop at 3000 meters;

2. According to different working conditions, flexibly open the appropriate number of engines to achieve multi-purpose of one machine;

3. Implement heat source management, and the key maximum temperature of the whole machine is not more than 350 °C, which greatly improves the safety of the whole vehicle;

4. The use of cylinder-type segmented hydraulic steel pipe reduces welds and improves safety performance by an order of magnitude;

5. Multiple engines back up each other, and if a single engine fails, the output power of other engines can be increased to compensate for continuous construction;

6. Add a health check system to detect the vibration of key components, evaluate the health status of the vehicle from time to time, and reasonably prompt the maintenance time;

7. Stainless steel pump head body and stainless steel low-pressure steel pipe are used to greatly improve the life of the pump;

8. The plateau performance is good, and the power does not drop at 3000 meters;

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all