Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

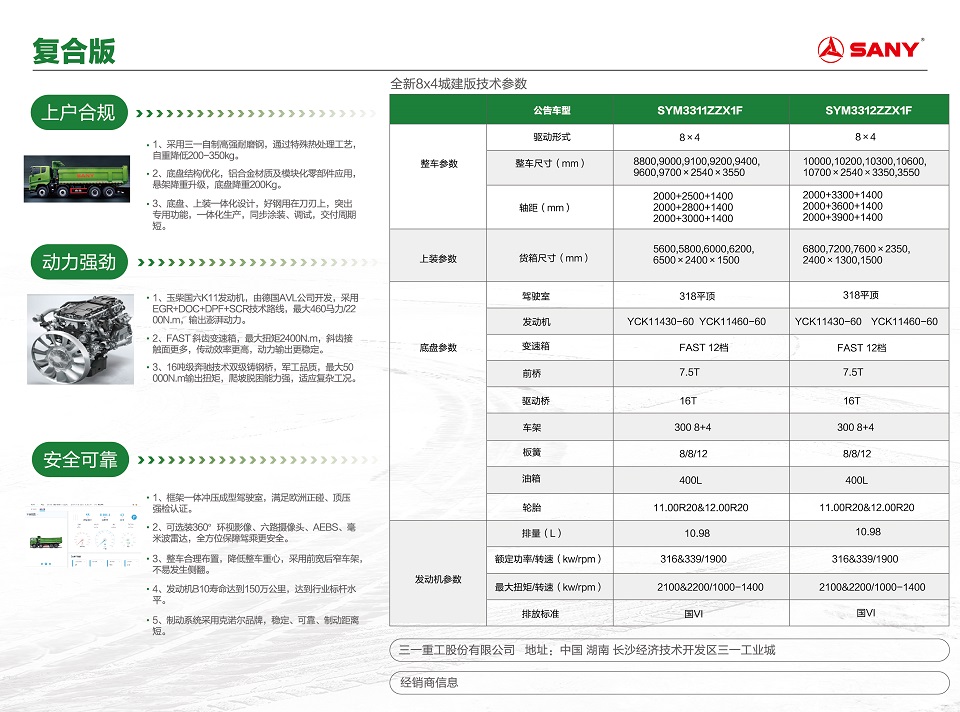

SYM3311ZZX1F

No. 2 project - 8×4 urban construction muck dump truck

8×4

10.98L

460PS

Applicable working conditions

Product Brochure Earthworks

Earthworks Dig the foundation

Dig the foundation Demolition works

Demolition worksProduct Details

Construction case

Performance parameters Product selling point

Drive form

8×4

wheelbase

2000+2500/2800/3000+1400mm

Vehicle size

8800/9000/9200/9400/9600/9800*2540*3250/3350/3550mm

Cargo box dimensions

5600/5800/6000/6200/6500/6800*2350/2400/2450*1500mm

cab

318 flat top

motor

Yuchai YCK11430/460-60

Gearbox

Fast 12JSDX240T

Front axle

7.5T

Drive axle

16T Beiben

Frame

300 8+4

Leaf springs

8/8/12

Fuel tanks

400L

tyre

12.00R20

Displacement

10.98L

Rated power/speed

339/1900kW/rpm

Maximum torque/speed

2200/1000-1500N·m/rpm

Emission standards

Country VI.

Drive form

8×4

Displacement

10.98L

Maximum horsepower

460PS

On-site compliance

Sany self-made high-strength wear-resistant steel is used, and the weight is reduced by 200-350kg through special heat treatment process.

The chassis structure is optimized, the aluminum alloy material and modular parts are applied, the suspension weight is upgraded, and the chassis weight is reduced by 200Kg.

The integrated design of chassis and bodywork, synchronous painting and debugging, and short delivery at the same time.

Powerful

Yuchai National VI K11 engine, developed by the German AVL company, adopts EGR+DOC+DPF+SCR technology route, and has strong power

The 16-ton Benji technology double-stage cast steel bridge has military quality, strong climbing ability, and adapts to complex working conditions

Safe and reliable

The frame integrated stamping and forming cab meets the European forward collision and top pressure strong inspection certification.

Optional 360° surround view image, six-way camera, AEBS, millimeter-wave radar, all-round protection of driving safety.

The vehicle is reasonably arranged, the center of gravity of the vehicle is reduced, and the front wide and rear narrow frame is not easy to roll over.

Sany self-made high-strength wear-resistant steel is used, and the weight is reduced by 200-350kg through special heat treatment process.

The chassis structure is optimized, the aluminum alloy material and modular parts are applied, the suspension weight is upgraded, and the chassis weight is reduced by 200Kg.

The integrated design of chassis and bodywork, synchronous painting and debugging, and short delivery at the same time.

Powerful

Yuchai National VI K11 engine, developed by the German AVL company, adopts EGR+DOC+DPF+SCR technology route, and has strong power

The 16-ton Benji technology double-stage cast steel bridge has military quality, strong climbing ability, and adapts to complex working conditions

Safe and reliable

The frame integrated stamping and forming cab meets the European forward collision and top pressure strong inspection certification.

Optional 360° surround view image, six-way camera, AEBS, millimeter-wave radar, all-round protection of driving safety.

The vehicle is reasonably arranged, the center of gravity of the vehicle is reduced, and the front wide and rear narrow frame is not easy to roll over.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all