Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

SSR260C-10H

26 tons C10 China IV full hydraulic dual-drive single-drum roller

177kW

26000kg

435/315kN

Applicable working conditions

Product Brochure Earthworks

Earthworks Stone works

Stone works highway

highway Railway/tunnel construction

Railway/tunnel construction Municipal utilities

Municipal utilities Water conservancy and hydropower

Water conservancy and hydropowerProduct Details

Construction case

Performance parameters Product selling point

Engine make and model

Shangchai SC7HG4

Rated power

177kW

Quality of work

26000kg

Front and rear load distribution

17000/9000kg

Vibration frequency

27/32Hz

Vibration frequency Low/High

27/32Hz

Minimum outside radius of turns

13640mm

Excitation force Large/small

435/315kN

Amplitude Big/Small

2.1/1.1mm

Theoretical climbing ability

50%

Rated power

177kW

Quality of work

26000kg

Excitation force

435/315kN

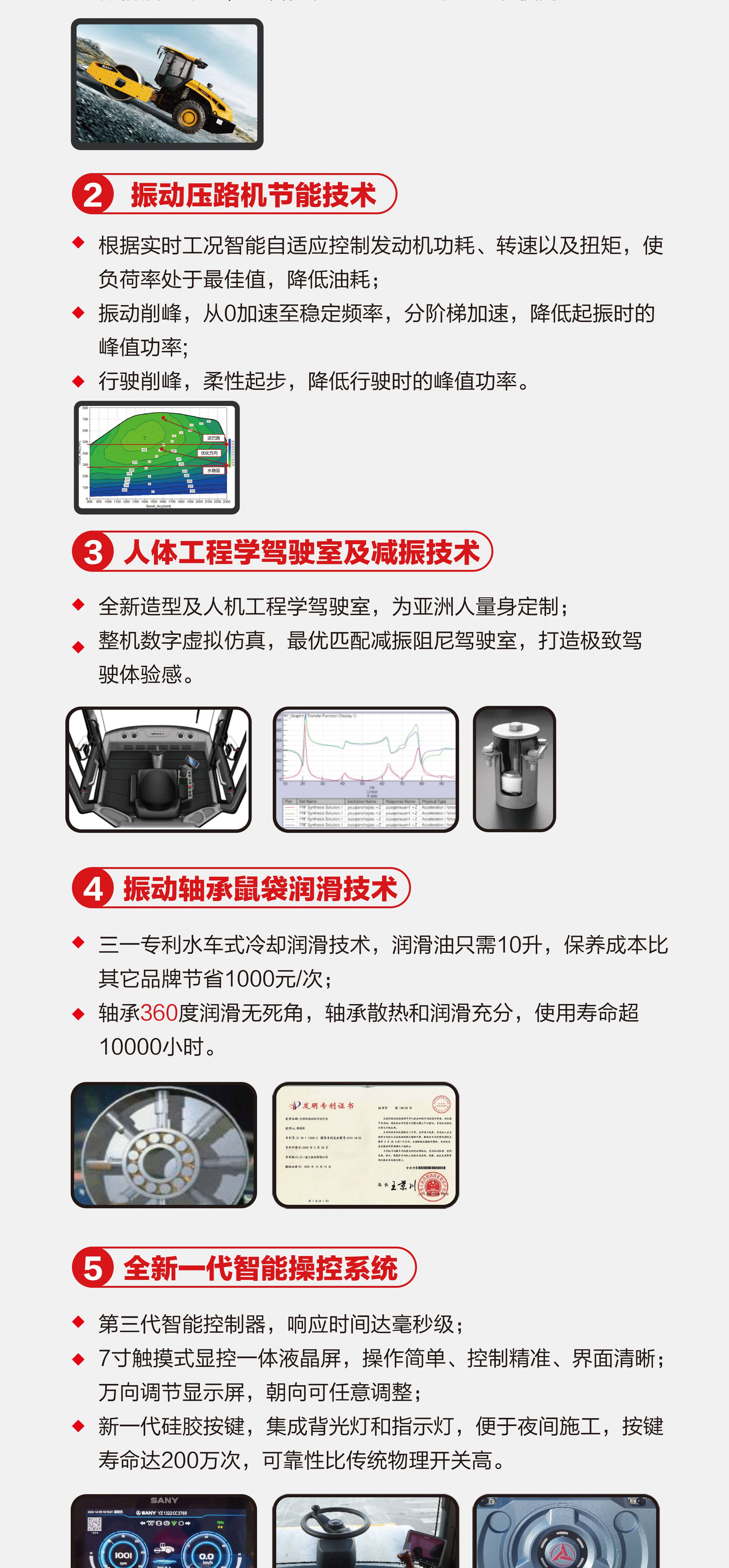

The compaction capacity of the industry is leading

Compaction thickness up to 1 m: forces up to 60 tonnes (17 tonnes for front wheel distribution + 43.5 tonnes for excitation); Dam compacted rockfill affects a depth of up to 1 metre;

Durable drum leather: 1.7 m diameter steel wheel, thickened and strengthened rim design, small deformation, wear resistance, suitable for heavy-duty compaction.

Climb the hill to get out of trouble

Climbing capacity 50%: steel drum and tire synchronous drive, standard rock tires, effectively avoid tire slippage during climbing, suitable for large ramp compaction operations;

Strong relief and suitable for all-terrain compaction: 4 working speeds, and the driving force of steel drum tires can be adjusted separately to effectively improve the ability to get out of trouble in the process of compaction on sand, wet soil and large slopes.

Safe and reliable

Safety and lifelong worry-free: three-level braking (service brake, parking brake, emergency braking) ensures 0 risks and 0 accidents in the equipment and construction process. The fully hydraulic wheel disc brake system is reliable and maintenance-free;

Reliable, durable and value-preserving core components: A new generation of predictive maintenance technology monitors the rear axle temperature, hydraulic oil cleanliness, engine oil, water vapor in real time, and intelligently prompts maintenance and problem solving to ensure the healthy and stable operation of the equipment.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all