Sany Heavy Industries Sany Heavy Industry (SH:600031)

Trinity International Sany International (HK:00631)

Trinity Renewable Trinity Renewable Energy (SH:688349)

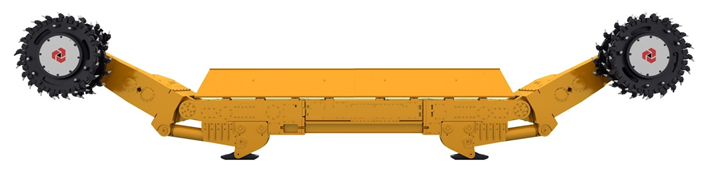

MG500/1340-WD type shearer

2022.01.25

Trinity reloaded

In January 2022, it attracted much attentionMG500/1340-WD Smart TypeShearersThe assembly and commissioning work was successfully completed.

As a member of the 1180 series shearers,The 1340 shearer has been comprehensively upgraded intelligently, and the whole machine is equipped with a 160kW crushing section and an automatic lifting top guard.

• Mining height range: 2.4-4.2m

• Power: 1340kW

• Cutting power: 2×500kW

• Traction power: 2×75kW

• Pumping station power: 30kW

• Crushing power: 160kW

• Drum diameter: Φ2240mm

• Production capacity: 4 million tons/year

The device will be sent soonGansu Huating Coal and Electricity Co., Ltd. Yanbei Coal MineUse. This 1340 shearer is the successor to the 980 shearer,The second 1180 series shearer purchased by Yanbei Coal Mine。

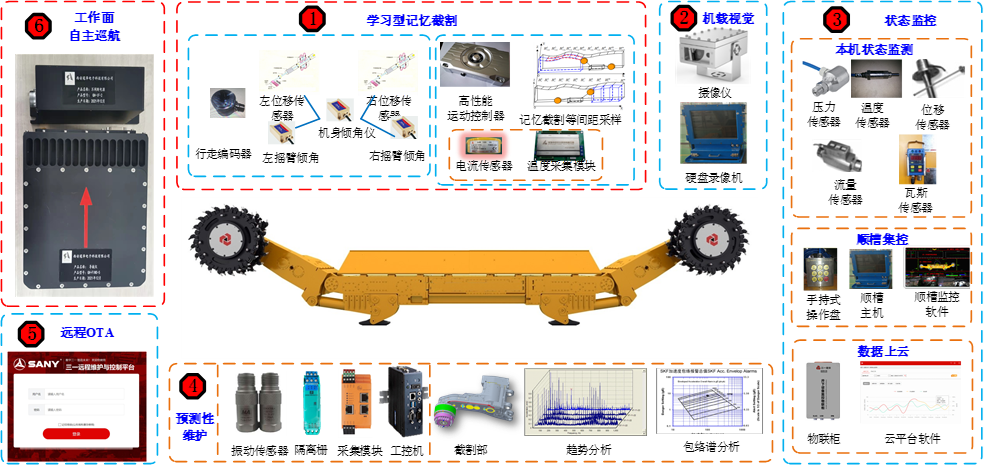

The 1340 shearer focuses on five major performances: safety, less manpower, perception, decision-making, and control, and is equipped with six major systems: learning memory interception, airborne vision, status monitoring, predictive maintenance, remote OTA, and autonomous cruise of the working face.It is an intelligent product with comprehensive perception, fault prediction and automatic control.

Learning memory truncation

• Accurately record parameters such as mining height, speed, and inclination angle;

• High positioning accuracy: repeat error ≤ 25mm;

• Flexible program architecture: up to 40 process segments can be configured;

• PWM closed-loop output: can achieve smooth control of the rocker arm at different speeds;

• Dynamically adjust the motor action to avoid long-term overheating and overloading of the motor, and extend the service life.

Onboard vision

The shearer is equipped with 4 cameras to convert the collected video images into Ethernet electrical signals for transmission. Real-time monitoring of roller changes, automatic video push and storage.

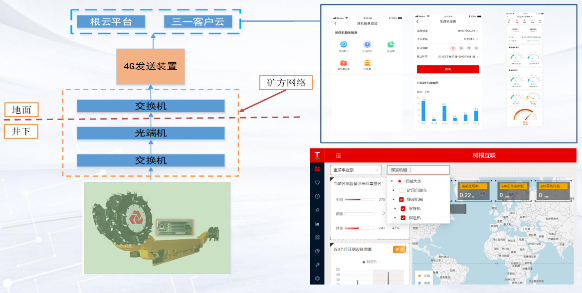

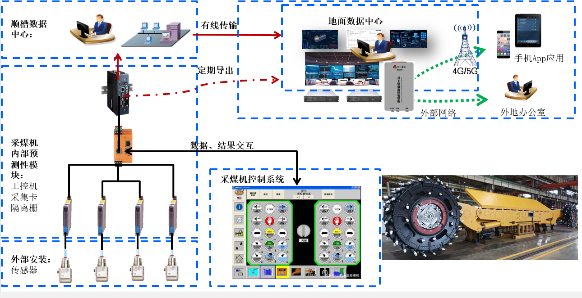

Status monitoring

Integrated monitoring service system, remote real-time access to underground shearers, remote visual monitoring to view the status information of shearers, and tracking the production status of the working face.

Predictive maintenance

Precise fault analysis to diagnose fault location, fault type, and severity. Based on the type of failure and historical data, analyze the possible trend of the next stage of failure and predict the remaining life of the failed part.

Remote OTA

It can realize remote update and debugging of shearer programs, which is convenient for timely and efficient handling of electrical system-related faults.

The working face cruises autonomously

The inertial navigation system accurately measures the running trajectory of the shearer and realizes automatic straightening to ensure the safe and automatic operation of the coal mining face.

Recommended products

0 comments

0 comments