Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Campaigns > Thin mining and high efficiency - Sany Heavy Installation MG330/730-WD series thin coal seam shearer

Thin mining and high efficiency - Sany Heavy Installation MG330/730-WD series thin coal seam shearer

2022.03.28

Trinity reloaded

In the mining of thin coal seam underground mines, there are generally complex working conditions such as faults, gangue, local thinning, and large dip angles, and "it is difficult to pass through the coal seam, it is difficult to load coal in a small drum, it is difficult to transport coal through low, and it is difficult to produce more faults and more stable" has become the main problem restricting the improvement of mining efficiency. So, how to achieve "It can be picked, loaded, transported, and used for a long timeIt is the key to achieving efficient mining of thin coal seams.

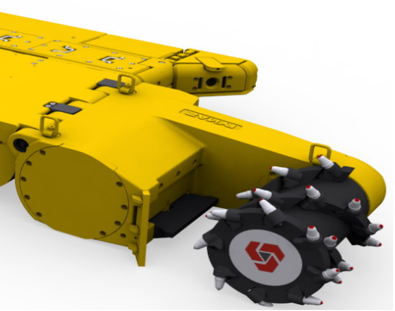

Sany MG330/730-WD seriesThin seam shearerBy adopting the self-developed suspension fuselage layout, configuring high-power C-shaped rocker arm and support system, a unique road of thin coal seam mining has been opened.

Picked

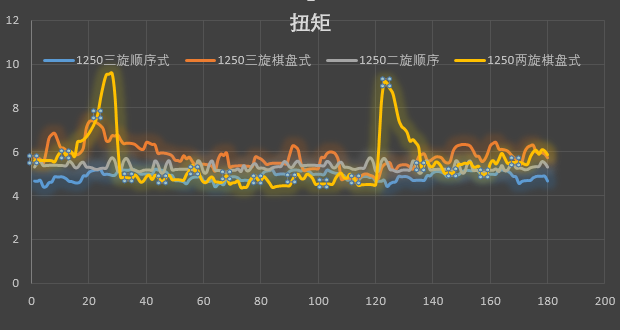

The single cutting power is 330kw, and the cutting density is 480Kw/㎡。 With Sany heavy-duty rock breaking drum, it can pass through F6 hardness coal seam.According to different coal quality, a variety of pick arrangement forms are customized to achieve efficient cutting of tough coal and hard coal.

Calculation of drum rock breaking efficiency

Fitted

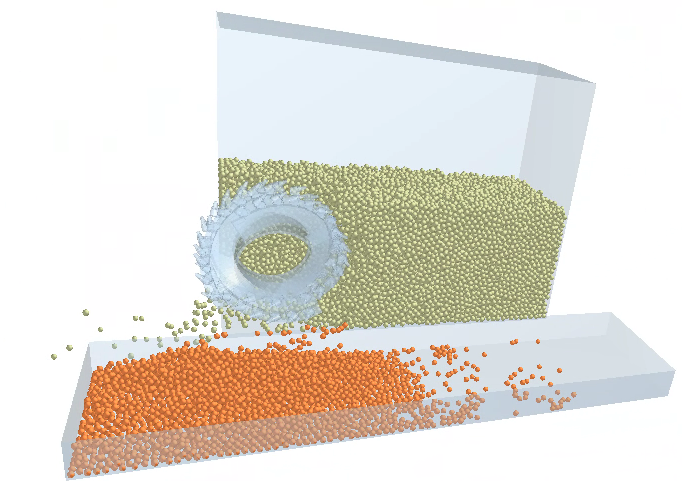

The cutting part adopts a C-shaped structure, which cuts coal with internal rotation and assists coal collection with shovel plate, which effectively improves the efficiency of coal loading. In order to solve the problem of coal loading difference in small drums, the key parameters such as spiral rise angle were optimized by three-dimensional simulation.Increase coal loading effect by 5.3%。

C-shaped internal rotation rocker arm andSimulation of drum coal loading optimization

Shipped out

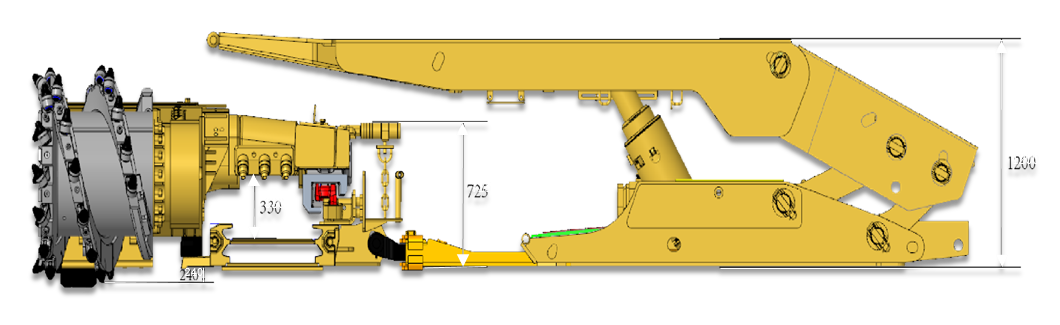

The whole machine is adoptedSuspended fuselage layoutWhen mining coal, the front drum cuts the bottom, and the fuselage is located in the coal wall as a whole. The structure can design the electronic control system and the traction transmission system inside the fuselage, so that the structure above the scraper can be the thinnest, effectively solve the contradiction between the height of the machine surface and the space of coal crossing, and can be configured with different scrapers for transportation.The coal space > 330mmto solve the problem of coal blockage in large coals.

At the same time, because the cutting part is arranged as a whole on the outside of the shovel plate groove, a large undercover amount can be realized, which is conducive to cutting through the upper and lower triangle coal.

Matching cross-sectional size

Use it for a long time

Through the development of new wear-resistant materials and casting materials, combined with advanced test and simulation methods, the average service life of key components has been increased by 25%.

·Walking wheelsDeep carburizing technology and multi-stage fitting tooth shape are used to meet the requirements of 1 million tons of coal mining;

·Guided sliding shoes: The application of cemented carbide and high fusion surfacing process, the service life is increased to more than 10 months;

·Large cast housing: Develop high-strength casting materials, optimize the heat treatment process, and increase the strength of the shell by 15%;

·Frequency convertersAnti-vibration means such as fixed-point reinforcement are used to meet the requirements of 8G anti-vibration;

·Drum: Self-developed alloy bean pick, pick consumption reduced by 15%.

High-strength walking wheels andInverter anti-vibration experiment

Wisdom of the heart

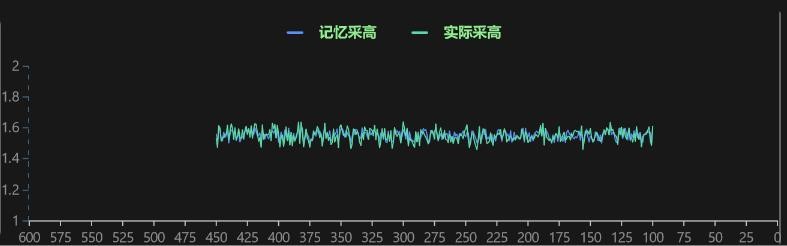

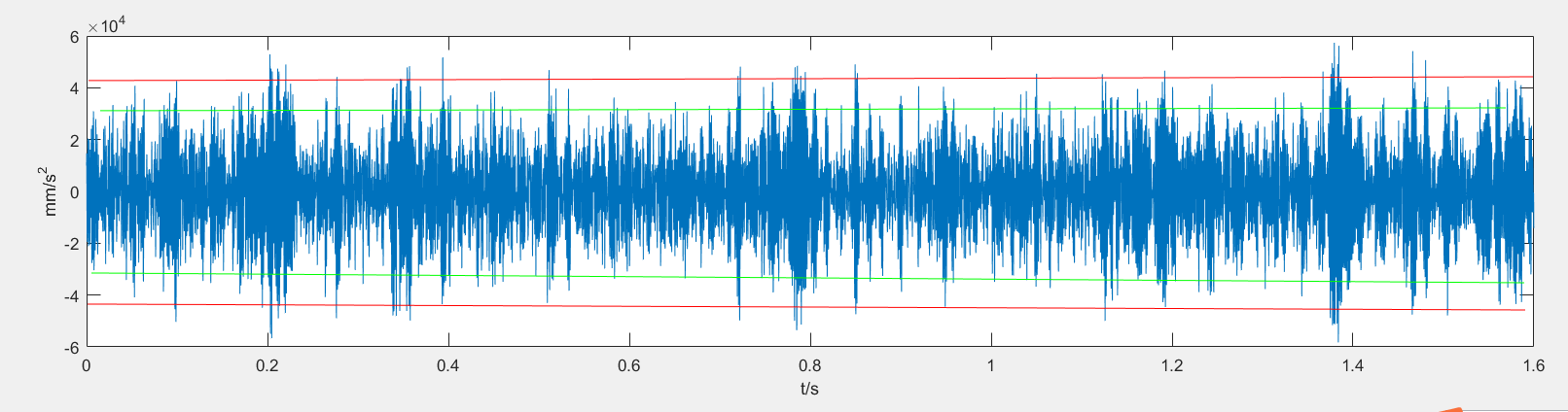

In order to meet the needs of intelligent mining, MG330/730-WD series thin coal seam shearers are equipped with a learning memory cutting system and a predictive maintenance system for the cutting department, and have been put into use in Shanxi Xingsheng Hongfa Coal Mine and Jixi Dongshan Coal Mine.The memory cutting error is ≤5cm, the fault diagnosis accuracy of the transmission system of the cutting part is ≥80%, and the life prediction accuracy is ≥80%.

Memory cut-off actual acquisition fitting curve

Predictive maintenance data

Sany thin coal seam shearer is committed to solving the problem of thin coal seam mining, and winning the trust and support of customers with high quality and service quality.

Since the beginning of 2021, Longmei Group has purchased 14 thin seam shearers.MG330/730-WD shearer during the use of Longmei Jixi Mining Bureau,It has set a mining record of 100,000 tons per month for many times, and has been recognized by customers for its extremely high mining efficiency and reliability.

In addition, in the face of extremely harsh all-rock working conditions,Customers in Sichuan also expressed their greatest trust in Sany with repurchases.

Recommended products

0 comments

Related testimonials

Build the Greater Bay Area together|Sany rotary excavator group is in full swing to create a Shenzhen skyline

2025.06.26

Su Chao & Sany Dream Linkage, Exclusive Benefits Revealed!

2025.06.26

Sany Heavy Machinery's first overseas factory localized supply chain return training ended successfully!

2025.06.26

0 comments